Archive for the ‘Innovation’ Category

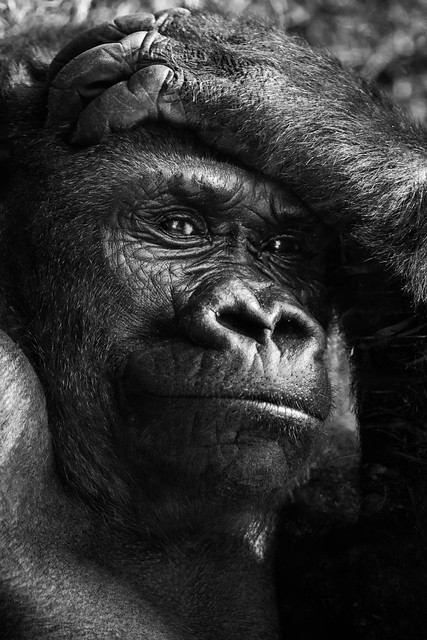

Uncertainty Isn’t All Bad

If you think you understand what your customers want, you don’t.

If you think you understand what your customers want, you don’t.

If you’re developing a new product for new customers, you know less.

If you’re developing a new technology for a new product for new customers, you know even less.

If you think you know how much growth a new product will deliver, you don’t.

If that new product will serve new customers, you know less.

If that new product will require a new technology, you know even less.

If you have to choose between project A and B, you’ll choose the one that’s most like what you did last time.

If project A will change the game and B will grow sales by 5%, you’ll play the game you played last time.

If project A and B will serve new customers, you’ll change one of them to serve existing customers and do that one.

If you think you know how the market will respond to a new product, it won’t make much of a difference.

If you don’t know how the market will respond, you may be onto something.

If you don’t know which market the product will serve, there’s a chance to create a whole new one.

If you know how the market will respond, do something else.

When we have a choice between certainty and upside, the choice is certain.

When we choose certainty over upside, we forget that the up-starts will choose differently.

When we have a lot to lose, we chose certainty.

And once it’s lost, we start over and choose uncertainty.

Image credit — Alexandra E Rust

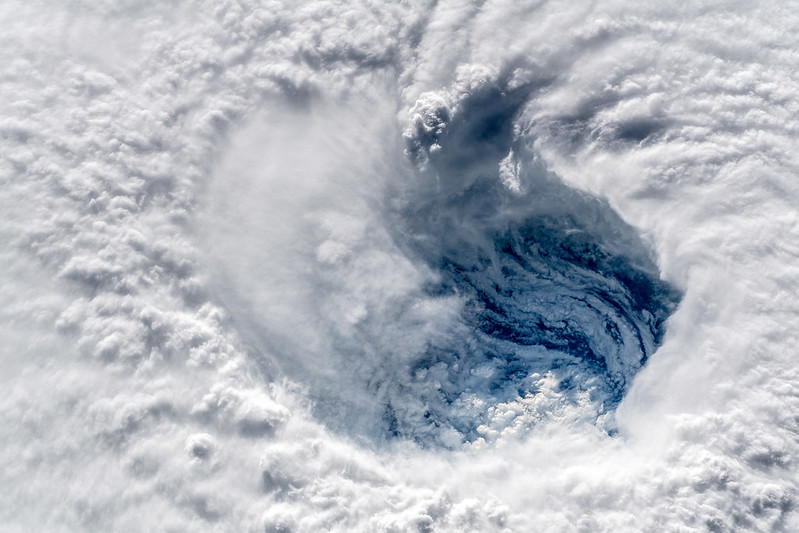

Companies, Acquisitions, Startups, and Hurricanes

If you run a company, the most important thing you can control is how you allocate your resources. You can’t control how the people in your company will respond to input, but you can choose the projects they work on. You can’t control which features and functions your customers will like, but you can choose which features and functions become part of the next product. And you can’t control if a new technology will work, but you can choose the design space to investigate. The open question – How to choose in a way that increases your probability of success?

If you want to buy a company, the most important thing you can control is how you allocate your resources. In this case, the resources are your hard-earned money and your choice is which company to buy. The open question – How to choose in a way that increases your probability of success?

If you want to invest in a startup company, the most important thing you can control is how you allocate your resources. This case is the same as the previous one – your money is the resource and the company you choose defines how you allocate your resources. This one is a little different in that the uncertainty is greater, but so is the potential reward. Again, the same open question – How to choose in a way that increases your probability of success?

Taking a step back, the three scenarios can be generalized into a category called a “system.” And the question becomes – how to understand the system in a way that improves resource allocation and increases your probability of success?

These people systems aren’t predictable in an if-A-then-B way. But they do have personalities or dispositions. They’ve got characteristics similar to hurricanes. A hurricane’s exact path cannot be forecasted, the meteorologist can use history and environmental conditions to broadly define regions where the probability of danger is higher. The meteorologist continually monitors the current state of the hurricane (the system as it is) and tracks its position over time to get an idea of its trajectory (a system’s momentum). The key to understanding where the hurricane could go next: where it is right now (current state), how it got there (how it has behaved over time), and how have other hurricanes tracked under similar conditions (its disposition). And it’s the same for systems.

To improve your understanding of how your system may respond, understand it as it is. Define the elements and how those elements interact. Then, work backward in time to understand previous generations of the system. Which elements were improved? Which ones were added? Then, like the meteorologist, start at the system’s genesis and move forward to the present to understand its path. Use the knowledge of its path and the knowledge of systems (it’s important to be the one that improves the immature elements of the system and systems follow S-curves until the S-curve flattens) to broadly define regions where the probability of success is higher.

These methods won’t guarantee success. But, they will help you choose projects, choose acquisitions, choose technologies, and choose startups in a way that increases your probability of success.

Image credit — Alexander Gerst

Disruption – the work that makes the best things obsolete.

I think the word “disruption” doesn’t help us do the right work. Instead, I use “innovation.” But that word has also lost much of its usefulness. There are different flavors of innovation and the flavor that maps to disruption is the flavor that makes things obsolete. This flavor of new work doesn’t improve things, it displaces them. So, when you see “innovation” in my posts, think “work that makes the best things obsolete.”

Doing work that makes the best things obsolete requires new behavior. Here’s a post that gives some tips to help make it easy for new behaviors to come to be. Within the blog post, there is a link to a short podcast that’s worth a listen. One Good Way to Change Behavior

And here’s a follow-on post about what gets in the way of new behavior. What’s in the way?

It’s difficult to define “disruption.” Instead of explaining what disruption is or isn’t, I like to use “no-to-yes.” Don’t improve the system by 3%, instead use no-to-yes to make the improved system do something the existing system cannot. Battle Success With No-to-Yes

Instead of “disruption” I like “compete with no one.” To compete with no one, you’ve got to make your services so fundamentally good that your competition doesn’t stand a chance. Compete With No One

Disruption, as a word, is not actionable. But here’s what is actionable: Choose to solve new problems. Choose to solve problems that will make today’s processes and outcomes worthless. Before you solve a problem ask yourself “Will the solution displace what we have today?” Innovation In Three Words

Here’s a nice operational definition of how to do disruption – Obsolete your best work.

And if you’re not yet out of gas, here are some posts that describe what gets in the way of new behavior and how to create the right causes and conditions for new behaviors to emerge.

Creating the Causes and Conditions for New Behavior to Grow

The only thing predictable about innovation is its unpredictability.

For innovation to flow, drive out fear.

Image credit — Thomas Wensing

The Difficulty of Commercializing New Concepts

If you have the data that says the market for the new concept is big enough, you waited too long.

If you have the data that says the market for the new concept is big enough, you waited too long.

If you require the data that verifies the market is big enough before pursuing new concepts, you’ll never pursue them.

If you’re afraid to trust the judgement of your best technologists, you’ll never build the traction needed to launch new concepts.

If you will sell the new concept to the same old customers, don’t bother. You already sold them all the important new concepts. The returns have already diminished.

If you must sell the new concept to new customers, it could create a whole new business for you.

If you ask your successful business units to create and commercialize new concepts, they’ll launch what they did last time and declare it a new concept.

If you leave it to your successful business units to decide if it’s right to commercialize a new concept created by someone else, they won’t.

If a new concept is so significant that it will dwarf the most successful business unit, the most successful business unit will scuttle it.

If the new concept is so significant it warrants a whole new business unit, you won’t make the investment because the sales of the yet-to-be-launched concept are yet to be realized.

If you can’t justify the investment to commercialize a new concept because there are no sales of the yet-to-be-launched concept, you don’t understand that sales come only after you launch. But, you’re not alone.

If a new concept makes perfect sense, you would have commercialized it years ago.

If the new concept isn’t ridiculed by the Status Quo, do something else.

If the new concept hasn’t failed three times, it’s not a worthwhile concept.

If you think the new concept will be used as you intend, think again.

If you’re sure a new concept will be a flop, you shouldn’t be. Same goes for the ones you’re sure will be successful.

If you’re afraid to trust your judgement, you aren’t the right person to commercialize new concepts.

And if you’re not willing to put your reputation on the line, let someone else commercialize the new concept.

Image credit – Melissa O’Donohue

Transcending a Culture of Continuous Improvement

We’ve been too successful with continuous improvement. Year-on-year, we’ve improved productivity and costs. We’ve improved on our existing products, making them slightly better and adding features.

Our recipe for success is the same as last year plus three percent. And because the customers liked the old one, they’ll like the new one just a bit more. And the sales can sell the new one because its sold the same way as the old one. And the people that buy the new one are the same people that bought the old one.

Continuous improvement is a tried-and-true approach that has generated the profits and made us successful. And everyone knows how to do it. Start with the old one and make it a little better. Do what you did last time (and what you did the time before). The trouble is that continuous improvement runs out of gas at some point. Each year it gets harder to squeeze out a little more and each year the return on investment diminishes. And at some point, the same old improvements don’t come. And if they do, customers don’t care because the product was already better than good enough.

But a bigger problem is that the company forgets to do innovative work. Though there’s recognition it’s time to do something different, the organization doesn’t have the muscles to pull it off. At every turn, the organization will revert to what it did last time.

It’s no small feat to inject new work into a company that has been successful with continuous improvement. A company gets hooked on the predictable results of continuous which grows into an unnatural aversion to all things different.

To start turning the innovation flywheel, many things must change. To start, a team is created and separated from the continuously improving core. Metrics are changed, leadership is changed and the projects are changed. In short, the people, processes, and tools must be built to deal with the inherent uncertainty that comes with new work.

Where continuous improvement is about the predictability of improving what is, innovation is about the uncertainty of creating what is yet to be. And the best way I know to battle uncertainty is to become a learning organization. And the best way to start that journey is to create formal learning objectives.

Define what you want to learn but make sure you’re not trying to learn the same old things. Learn how to create new value for customers; learn how to deliver that value to new customers; learn how to deliver that new value in new ways (new business models.)

If you’re learning the same old things in the same old way, you’re not doing innovation.

Innovation Truths

If it’s not different, it can’t be innovation.

If it’s not different, it can’t be innovation.

With innovation, ideas are the easy part. The hard part is creating the engine that delivers novel value to customers.

The first goal of an innovation project is to earn the right to do the second hardest thing. Do the hardest thing first.

Innovation is 50% customer, 50% technology and 75% business model.

If you know how it will turn out, it’s not innovation.

Don’t invest in a functional prototype until customers have placed orders for the sell-able product.

If you don’t know how the customer will benefit from your innovation, you don’t know anything.

If your innovation work doesn’t threaten the status quo, you’re doing it wrong.

Innovation moves at the speed of people.

If you know when you’ll be finished, you’re not doing innovation.

With innovation, the product isn’t your offering. Your offering is the business model.

If you’re focused on best practices, you’re not doing innovation. Innovation is about doing things for the first time.

If you think you know what the customer wants, you don’t.

Doing innovation within a successful company is seven times hard than doing it in a startup.

If you’re certain, it’s not innovation.

With innovation, ideas and prototypes are cheap, but building the commercialization engine is ultra-expensive.

If no one will buy it, do something else.

Technical roadblocks can be solved, but customer/market roadblocks can be insurmountable.

The first thing to do is learn if people will buy your innovation.

With innovation, customers know what they don’t want only after you show them your offering.

With innovation, if you’re not scared to death you’re not trying hard enough.

The biggest deterrent to innovation is success.

Image credit — Sherman Geronimo-Tan

Seeing Things as They Can’t Be

When there’s a big problem, the first step is to define what’s causing it. To do that, based on an understanding of the physics, a sequence of events is proposed and then tested to see if it replicates the problem. In that way, the team must understand the system as it is before the problem can be solved.

When there’s a big problem, the first step is to define what’s causing it. To do that, based on an understanding of the physics, a sequence of events is proposed and then tested to see if it replicates the problem. In that way, the team must understand the system as it is before the problem can be solved.

Seeing things as they are. The same logic applies when it’s time to improve an existing product or service. The first thing to do is to see the system as it is. But seeing things as they are is difficult. We have a tendency to see things as we want them or to see them in ways that make us look good (or smart). Or, we see them in a way that justifies the improvements we already know we want to make.

To battle our biases and see things as they are, we use tools such as block diagrams to define the system as it is. The most important element of the block diagram is clarity. The first revision will be incorrect, but it must be clear and explicit. It must describe things in a way that creates a singular understanding of the system. The best block diagrams can be interpreted only one way. More strongly, if there’s ambiguity or lack of clarity, the thing has not yet risen to the level of a block diagram.

The block diagram evolves as the team converges on a single understanding of things as they are. And with a diagram of things as they are, a solution is readily defined and validated. If when tested the proposed solution makes the problem go away, it’s inferred that the team sees things as they are and the solution takes advantage of that understanding to make the problem go away.

Seeing things as they may be. Even whey the solution fixes the problem, the team really doesn’t know if they see things as they are. Really, all they know is they see things as they may be. Sure, the solution makes the problem go away, but it’s impossible to really know if the solution captures the physics of failure. When the system is large and has a lot of moving parts, the team cannot see things as they are, rather, they can only see the system as it may be. This is especially true if the system involves people, as people behave differently based on how they feel and what happened to them yesterday.

There’s inherent uncertainty when working with larger systems and systems that involve people. It’s not insurmountable, but you’ve got to acknowledge that your understanding of the system is less than perfect. If your company is used to solving small problems within small systems, there will be little tolerance for the inherent uncertainty and associated unpredictability (in time) of a solution. To help your company make the transition, replace the language of “seeing things as they are” with “seeing things as they may be.” The same diagnostic process applies, but since the understanding of the system is incomplete or wrong, the proposed solutions cannot not be pre-judged as “this will work” and “that won’t work.” You’ve got to be open to all potential solutions that don’t contradict the system as it may be. And you’ve got to be tolerant of the inherent unpredictability of the effort as a whole.

Seeing things as they could be. To create something that doesn’t yet exist, something does things like never before, something altogether new, you’ve got to stand on top of your understanding of the system and jump off. Whether you see things as they are or as they may be, the new system will be different. It’s not about diagnosing the existing system; it’s about imagining the system as it could be. And there’s a paradox here. The better you understand the existing system, the more difficulty you’ll have imagining the new one. And, the more success the company has had with the system as it is, the more resistance you’ll feel when you try to make the system something it could be.

Seeing things as they could be takes courage – courage to obsolete your best work and courage to divest from success. The first one must be overcome first. Your body creates stress around the notion of making yourself look bad. If you can create something altogether better, why didn’t you do it last time? There’s a hit to the ego around making your best work look like it’s not all that good. But once you get over all that, you’ve earned the right to go to battle with your organization who is afraid to move away from the recipe responsible for all the profits generated over the last decade.

But don’t look at those fears as bad. Rather, look at them as indicators you’re working on something that could make a real difference. Your ego recognizes you’re working on something better and it sends fear into your veins. The organization recognizes you’re working on something that threatens the status quo and it does what it can to make you stop. You’re onto something. Keep going.

Seeing things as they can’t be. This is rarified air. In this domain you must violate first principles. In this domain you’ve got to run experiments that everyone thinks are unreasonable, if not ill-informed. You must do the opposite. If your product is fast, your prototype must be the slowest. If the existing one is the heaviest, you must make the lightest. If your reputation is based on the highest functioning products, the new offering must do far less. If your offering requires trained operators, the new one must prevent operator involvement.

If your most seasoned Principal Engineer thinks it’s a good idea, you’re doing it wrong. You’ve got to propose an idea that makes the most experienced people throw something at you. You’ve got to suggest something so crazy they start foaming at the mouth. Your concepts must rip out their fillings. Where “seeing things as they could be” creates some organizational stress, “seeing things as they can’t be” creates earthquakes. If you’re not prepared to be fired, this is not the domain for you.

All four of these domains are valuable and have merit. And we need them all. If there’s one message it’s be clear which domain you’re working in. And if there’s a second message it’s explain to company leadership which domain you’re working in and set expectations on the level of uncertainty and unpredictability of that domain.

Image credit – David Blackwell.

You don’t need more ideas.

Innovation isn’t achieved by creating more ideas. Innovation is realized when ideas are transformed into commercialized products and services. Innovation is realized when ideas are transformed into new business models that deliver novel usefulness to customers and deliver increased revenues to the company.

Innovation isn’t achieved by creating more ideas. Innovation is realized when ideas are transformed into commercialized products and services. Innovation is realized when ideas are transformed into new business models that deliver novel usefulness to customers and deliver increased revenues to the company.

In a way, creating ideas that languish in their own shadow is worse than not creating any ideas at all. If you don’t have any ideas, at least you didn’t spend the resources to create them and you don’t create the illusion that you’re actually making progress. In that way, it’s better to avoid creating new ideas if you’re not going to do anything with them. At least your leadership team will not be able to rationalize that everything will be okay because you have an active idea generation engine.

Before you schedule your next innovation session, don’t. Reason 1 – it’s not an innovation session, it’s an ideation session. Reason 2 – you don’t have resources to do anything with the best ideas so you’ll spend the resources and nothing will come of it. To improve the return on investment, don’t make the investment because there’ll be no return.

Truth is, you already have amazing ideas to grow your company. Problem is, no one is listening to the people with the ideas. And the bigger problem – because no one listened over the last ten years, the people with the ideas have left the company or stopped trying to convince you they have good ideas. Either way, you’re in trouble and creating more ideas won’t help you. Your culture is such that new ideas fall on deaf ears and funding to advance new concepts loses to continuous improvement.

If you do want to hold an ideation event to create new ideas that will reinvent your company, there are ways to do it effectively. First, define the customer of the ideation event. This is the person who is on the hook to commercialize things that will grow the business. This is the person who will have a career problem if ideas aren’t implemented. This is the person who can allocate the resources to turn the ideas into commercialized products, services. If this person isn’t an active advocate for the ideation event, don’t hold it. If this person will not show up to the report out of the ideation event, don’t hold it. If this person does not commit to advancing the best ideas, don’t hold the event.

Though innovation and ideas start with “i”, they’re not the same. Ideas are inexpensive to create but deliver no value. Innovation is expensive and delivers extreme value to customers and the company. If you’re not willing to convert the ideas into something that delivers values to customers, save the money and do continuous improvement. Your best people will leave, but at least you won’t waste money on creating ideas that will die on the vine.

If the resources aren’t lined up to run with the ideas, don’t generate the them. If you haven’t allocated the funding for the follow-on work, don’t create new ideas. If the person who is charged with growing the business isn’t asking for new ideas, don’t hold the ideation event.

You already have too many ideas. But what you lack is too few active projects to convert the best ideas into products and services that generate value for your customers and growth for your company.

Stop creating new ideas and start delivering novel usefulness to your customers.

Image credit – Marco Nürnberger

Before solving, learn more about the problem.

Ideas are cheap, but converting them into a saleable product and building the engine to make it all happen is expensive. Before spending the big money, spend more time than you think reasonable to answer these three questions.

Ideas are cheap, but converting them into a saleable product and building the engine to make it all happen is expensive. Before spending the big money, spend more time than you think reasonable to answer these three questions.

Is the problem big enough? There’s no sense spending the time and money to solve a problem unless you have a good idea the payback is worth the cost. Before spending the money to create the solution, spend the time to assess the benefits that will come from solving the problem.

Before you can decide if the problem is big enough, you have to define the problem and know who has it. One of the best ways to do this is to define how things are done today. Draw a block diagram that defines the steps potential customers follow or draw a picture of how they do things today. Define the products/services they use today and ask them what it would mean if you solved their problem. What’s particularly difficult at this point is they may not know they have a problem.

But before moving on, formalize who has the problem. Define the attributes of the potential customers and figure out how many have the same attributes and, possibly, the same problem. Define the segments narrowly to make sure each segment does, in fact, have the same problem. There will be a tendency to paint with broad strokes to increase the addressable market, but stay narrow and maintain focus on a tight group of potential customers.

Estimate the value of the solution based on how it compares to the existing alternative. And the only ones who can give you this information are the potential customers. And the only way they can give you the information is if you interview them and watch them work. And with this detailed knowledge, figure out the number of potential customers who have the problem. Do all this BEFORE any solving.

Will they pay for it? The only way to know if potential customers will pay for your solution is to show them an offering – a description of your value proposition and how it differs from the existing alternatives, a demo (a mockup of a solution and not a functional prototype) and pricing. (See LEANSTACK for more on an offering.) There will be a tendency to wait until the solution is ready, but don’t wait. And there will be a reluctance attach a price to the solution, but that’s the only way you’ll know how much they value your solution. And there will be difficulty defining a tight value proposition because that requires you to narrowly define what the solution does for the potential customer. And that’s scary because the value proposition will be clear and understandable and the potential customer will understand it well enough to decide they if they like it or not.

If you don’t assign a price and ask them to buy it, you’ll never know if they’ll buy it in real life.

Can you deliver it? List all the elements that must come together. Can you make it? Can you sell it? Can you ship it? Can you service it? Are your partners capable and committed? Do you have the money do put everything in place?

Like with a chain, it takes one bad link to make the whole thing fall apart. Figure out if any of your links are broken or missing. And don’t commit resources until they’re all in place and ready to go.

Image credit — Matthias Ripp

The Most Powerful Question

Artificial intelligence, 3D printing, robotics, autonomous cars – what do they have in common? In a word – learning.

Artificial intelligence, 3D printing, robotics, autonomous cars – what do they have in common? In a word – learning.

Creativity, innovation and continuous improvement – what do they have in common? In a word – learning.

And what about lifelong personal development? Yup – learning.

Learning results when a system behaves differently than your mental model. And there four ways make a system behave differently. First, give new inputs to an existing system. Second, exercise an existing system in a new way (for example, slow it down or speed it up.) Third, modify elements of the existing system. And fourth, create a new system. Simply put, if you want a system to behave differently, you’ve got to change something. But if you want to learn, the system must respond differently than you predict.

If a new system performs exactly like you expect, it isn’t a new system. You’re not trying hard enough.

When your prediction is different than how the system actually behaves, that is called error. Your mental model was wrong and now, based on the new test results, it’s less wrong. From a learning perspective, that’s progress. But when companies want predictable results delivered on a predictable timeline, error is the last thing they want. Think about how crazy that is. A company wants predictable progress but rejects the very thing that generates the learning. Without error there can be no learning.

If you don’t predict the results before you run the test, there can be no learning.

It’s exciting to create a new system and put it through its paces. But it’s not real progress – it’s just activity. The valuable part, the progress part, comes only when you have the discipline to write down what you think will happen before you run the test. It’s not glamorous, but without prediction there can be no error.

If there is no trial, there can be no error. And without error, there can be no learning.

Let’s face it, companies don’t make it easy for people to try new things. People don’t try new things because they are afraid to be judged negatively if it “doesn’t work.” But what does it mean when something doesn’t work? It means the response of the new system is different than predicted. And you know what that’s called, right? It’s called learning.

When people are afraid to try new things, they are afraid to learn.

We have a language problem that we must all work to change. When you hear, “That didn’t work.”, say “Wow, that’s great learning.” When teams are told projects must be “on time, on spec and on budget”, ask the question, “Doesn’t that mean we don’t want them to learn?”

But, the whole dynamic can change with this one simple question – “What did you learn?” At every meeting, ask “What did you learn?” At every design review, ask “What did you learn?” At every lunch, ask “What did you learn?” Any time you interact with someone you care about, find a way to ask, “What did you learn?”

And by asking this simple question, the learning will take care of itself.

Image credit m.shattock

Seeing What Isn’t There

It’s relatively straightforward to tell the difference between activities that are done well and those that are done poorly. Usually sub-par activities generate visual signals to warn us of their misbehavior. A bill isn’t paid, a legal document isn’t signed or the wrong parts are put in the box. Though the specifics vary with context, the problem child causes the work product to fall off the plate and make a mess on the floor.

It’s relatively straightforward to tell the difference between activities that are done well and those that are done poorly. Usually sub-par activities generate visual signals to warn us of their misbehavior. A bill isn’t paid, a legal document isn’t signed or the wrong parts are put in the box. Though the specifics vary with context, the problem child causes the work product to fall off the plate and make a mess on the floor.

We have tools to diagnose the fundamental behind the symptom. We can get to root cause. We know why the plate was dropped. We know how to define the corrective action and implement the control mechanism so it doesn’t happen again. We patch up the process and we’re up and running in no time. This works well when there’s a well-defined in place, when process is asked to do what it did last time, when the inputs are the same as last time and when the outputs are measured like they were last time.

However, this linear thinking works terribly when the context changes. When the old processes are asked to do new work, the work hits the floor like last time, but the reason it hits the floor is fundamentally different. This time, it’s not that an activity was done poorly. Rather, this time there’s something missing altogether. And this time our linear-thinker toolbox won’t cut it. Sure, we’ll try with all our Six Sigma might, but we won’t get to root cause. Six Sigma, lean and best practices can fix what’s broken, but none of them can see what isn’t there.

When the context changes radically, the work changes radically. New-to-company activities are required to get the new work done. New-to-industry tools are needed to create new value. And, sometimes, new-to-world thinking is the only thing that will do. The trick isn’t to define the new activity, choose the right new tool or come up with the new thinking. The trick is to recognize there’s something missing, to recognize there’s something not there, to recognize there’s a need for something new. Whether it’s an activity, a tool or new thinking, we’ve got to learn to see what’s not there.

Now the difficult part – how to recognize there’s something missing. You may think the challenging part is to figure out what’s needed to fill the void, but it isn’t. You can’t fill a hole until you see it as a hole. And once everyone agrees there’s a hole, it’s pretty easy to buy the shovels, truck in some dirt and get after it. But if don’t expect holes, you won’t see them. Sure, you’ll break your ankle, but you won’t see the hole for what it is.

If the work is new, look for what’s missing. If the problem is new, watch out for holes. If the customer is new, there will be holes. If the solution is new, there will be more holes.

When the work is new, you will twist your ankle. And when you do, grab the shovels and start to put in place what isn’t there.

Image credit – Tony Atler

Mike Shipulski

Mike Shipulski