Archive for the ‘Design Engineers’ Category

The best time to design cost out of our products is now.

With inflation on the rise and sales on the decline, the time to reduce costs is now.

With inflation on the rise and sales on the decline, the time to reduce costs is now.

But before you can design out the cost you’ve got to know where it is. And the best way to do that is to create a Pareto chart that defines product cost for each subassembly, with the highest cost subassemblies on the left and the lowest cost on the right. Here’s a pro tip – Ignore the subassemblies on the right.

Use your costed Bill of Materials (BOMs) to create the Paretos. You’ll be told that the BOMs are wrong (and they are), but they are right enough to learn where the cost is.

For each of the highest-cost subassemblies, create a lower-level Pareto chat that sorts the cost of each piece-part from highest to lowest. The pro tip applies here, too – Ignore the parts on the right.

Because the design community designed in the cost, they are the ones who must design it out. And to help them prioritize the work, they should be the ones who create the Pareto charts from the BOMs. They won’t like this idea, but tell them they are the only ones who can secure the company’s future profits and buy them lots of pizza.

And when someone demands you reduce labor costs, don’t fall for it. Labor cost is about 5% of the product cost, so reducing it by half doesn’t get you much. Instead, make a Pareto chart of part count by subassembly. Focus the design effort on reducing the part count of subassemblies on the left. Pro tip – Ignore the subassemblies on the right. The labor time to assemble parts that you design out is zero, so when demand returns, you’ll be able to pump out more products without growing the footprint of the factory. But, more importantly, the cost of the parts you design out is also zero. Designing out the parts is the best way to reduce product costs.

Pro tip – Set a cost reduction goal of 35%. And when they complain, increase it to 40%.

In parallel to the design work to reduce part count and costs, design the test fixtures and test protocols you’ll use to make sure the new, lower-cost design outperforms the existing design. Certainly, with fewer parts, the new one will be more reliable. Pro tip – As soon as you can, test the existing design using the new protocols because the only way to know if the new one is better is to measure it against the test results of the old one.

And here’s the last pro tip – Start now.

Image credit — aisletwentytwo

Stop reusing old ideas and start solving new problems.

Creating new ideas is easy. Sit down, quiet your mind, and create a list of five new ideas. There. You’ve done it. Five new ideas. It didn’t take you a long time to create them. But ideas are cheap.

Creating new ideas is easy. Sit down, quiet your mind, and create a list of five new ideas. There. You’ve done it. Five new ideas. It didn’t take you a long time to create them. But ideas are cheap.

Converting ideas into sellable products and selling them is difficult and expensive. A customer wants to buy the new product when the underlying idea that powers the new product solves an important problem for them. In that way, ideas whose solutions don’t solve important problems aren’t good ideas. And in order to convert a good idea into a winning product, dirt, rocks, and sticks (natural resources) must be converted into parts and those parts must be assembled into products. That is expensive and time-consuming and requires a factory, tools, and people that know how to make things. And then the people that know how to sell things must apply their trade. This, too, adds to the difficulty and expense of converting ideas into winning products.

The only thing more expensive than converting new ideas into winning products is reusing your tired, old ideas until your offerings run out of sizzle. While you extend and defend, your competitors convert new ideas into new value propositions that bring shame to your offering and your brand. (To be clear, most extend-and-defend programs are actually defend-and-defend programs.) And while you reuse/leverage your long-in-the-tooth ideas, start-ups create whole new technologies from scratch (new ideas on a grand scale) and pull the rug out from under you. The trouble is that the ultra-high cost of extend-and-defend is invisible in the short term. In fact, when coupled with reuse, it’s highly profitable in the moment. It takes years for the wheels to fall off the extend-and-defend bus, but make no mistake, the wheels fall off.

When you find the urge to create a laundry list of new ideas, don’t. Instead, solve new problems for your customers. And when you feel the immense pressure to extend and defend, don’t. Instead, solve new problems for your customers.

And when all that gets old, repeat as needed.

“Cave paintings” by allspice1 is licensed under CC BY-ND 2.0

Advice To Young Design Engineers

If your solution isn’t sold to a customer, you didn’t do your job. Find a friend in Marketing.

If your solution can’t be made by Manufacturing, you didn’t do your job. Find a friend in Manufacturing.

Reuse all you can, then be bold about trying one or two new things.

Broaden your horizons.

Before solving a problem, make sure you’re solving the right one.

Don’t add complexity. Instead, make it easy for your customers.

Learn the difference between renewable and non-renewable resources and learn how to design with the renewable ones.

Learn how to do a Life Cycle Assessment.

Learn to see functional coupling and design it out.

Be afraid but embrace uncertainty.

Learn how to communicate your ideas in simple ways. Jargon is a sign of weakness.

Before you can make sure you’re solving the right problem, you’ve got to know what problem you’re trying to solve.

Learn quickly by defining the tightest learning objective.

Don’t seek credit, seek solutions. Thrive, don’t strive.

Be afraid, and run toward the toughest problems.

Help people. That’s your job.

Image credit – Marco Verch

Creating a brand that lasts.

One of the best ways to improve your brand is to improve your products. The most common way is to provide more goodness for less cost – think miles per gallon. Usually it’s a straightforward battle between market leaders, where one claims quantifiable benefit over the other – Ours gets 40 mpg and theirs doesn’t. And the numbers are tied to fully defined test protocols and testing agencies to bolster credibility. Here’s the data. Buy ours

One of the best ways to improve your brand is to improve your products. The most common way is to provide more goodness for less cost – think miles per gallon. Usually it’s a straightforward battle between market leaders, where one claims quantifiable benefit over the other – Ours gets 40 mpg and theirs doesn’t. And the numbers are tied to fully defined test protocols and testing agencies to bolster credibility. Here’s the data. Buy ours

But there’s a more powerful way to improve your brand, and that’s to map your products to reliability. It’s far a more difficult game than the quantified head-to-head comparison of fuel economy and it’s a longer play, but done right, it’s a lasting play that is difficult to beat. Run the thought experiment: think about the brands you associate with reliability. The brands that come to mind are strong, lasting brands, brands with staying power, brands whose products you want to buy, brands you don’t want to compete against. When you buy their products you know what you’re going to get. Your friends tell you stories about their products.

There’s a complete a complete tool set to create products that map to reliability, and they work. But to work them, the commercialization team has to have the right mindset. The team must have the patience to formally define how all the systems work and how they interact. (Sounds easy, but it can be painfully time consuming and the level of detail is excruciatingly extreme.) And they have to be willing to work through the discomfort or developing a common understanding how things actually work. (Sounds like this shouldn’t be an issue, but it is – at the start, everyone has a different idea on how the system works.) But more importantly, they’ve got to get over the natural tendency to blame the customer for using the product incorrectly and learn to design for unintended use.

The team has got to embrace the idea that the product must be designed for use in unpredictable ways in uncontrolled conditions. Where most teams want to narrow the inputs, this team designs for a wider range of inputs. Where it’s natural to tighten the inputs, this team designs the product to handle a broader set of inputs. Instead of assuming everything will work as intended, the team must assume things won’t work as intended (if at all) and redesign the product so it’s insensitive to things not going as planned. It’s strange, but the team has to design for hypothetical situations and potential problems. And more strangely, it’s not enough to design for potential problems the team knows about, they’ve got to design for potential problems they don’t know about. (That’s not a typo. The team must design for failure modes it doesn’t know about.)

How does a team design for failure modes it doesn’t know about? They build a computer-based behavioral model of the system, right down to the nuts, bolts and washers, and they create inputs that represent the environment around the system. They define what each element does and how it connects to the others in the system, capturing the governing physics and propagation paths of connections. Then they purposefully break the functions using various classes of failure types, run the analysis and review the potential causes. Or, in the reverse direction, the team perturbs the system’s elements with inputs and, as the inputs ripple through the design, they find previously unknown undesirable (harmful) functions.

Purposefully breaking the functions in known ways creates previously unknown potential failure causes. The physics-based characterization and the interconnection (interaction) of the system elements generate unpredicted potential failure causes that can be eliminated through design. In that way, the software model helps find potential failures the team did not know about. And, purposefully changing inputs to the system, again through the physics and interconnection of the elements, generates previously unknown harmful functions that can be designed out of the product.

If you care about the long-term staying power of your brand, you may want to take a look at TechScan, the software tool that makes all this possible.

Image credit — Chris Ford.

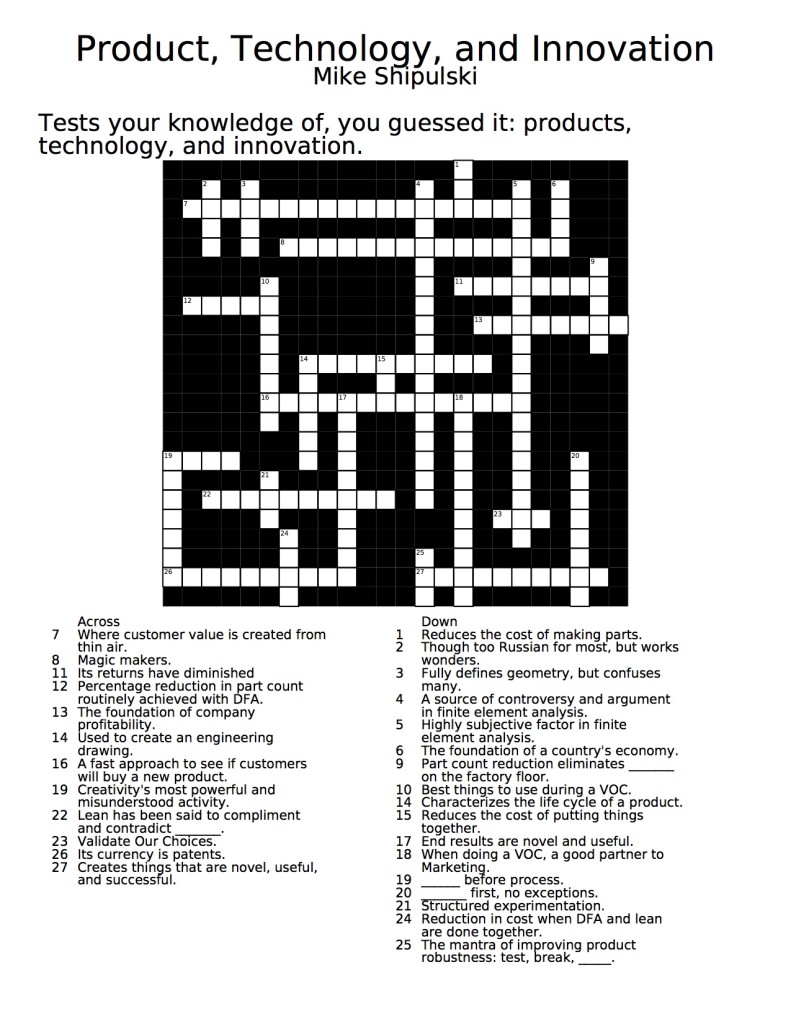

Crossword Puzzle – Product, Technology, Innovation

Here’s something a little different – a crossword puzzle to test your knowledge on products, technology, and innovation. Complete the puzzle using the image below, or download it (and answer key) using the green arrows below, and take your time with it over the Thanksgiving holiday.

[wpdm_file id=5]

[wpdm_file id=4]

What They Didn’t Teach Me in Engineering School

The technical stuff is the easy part. Technical systems respond predictably, but people don’t.

The technical stuff is the easy part. Technical systems respond predictably, but people don’t.

There’s nothing worse than solving the wrong problem, so before you start solving you’ve better done a whole lot of defining.

There is no exact answer; engineering is all about judgment.

Organizational structure is important. Whatever the structure, see its strengths and make them work for you. If you try to fight it, it will eat you.

Innovation isn’t about ideas, innovation is about commercializing ideas.

Engineering analysis can win minds, but not hearts. And hearts govern minds.

The engineer’s role is not to minimize risk; it’s to understand the commercial reward and take risk accordingly.

What people believe is far more powerful than what they think.

New technology threatens status quoers, and, in turn, they block it.

There is no problem unless someone important thinks there’s one.

All technical systems are really human systems masquerading as technical systems.

If you let it, fear dominates. Be afraid and do it anyway. But along the way, keep in mind that others are too afraid to try.

Engineering is not sane and rational; engineering is about people.

Engineering Incantations

Know what’s new in the new design. To do that, ask for a reuse analysis and divvy up newness into three buckets – new to your company, new to your industry, new to world. If the buckets are too big, jettison some newness, and if there’s something in the new-to-world bucket, be careful.

Know what’s new in the new design. To do that, ask for a reuse analysis and divvy up newness into three buckets – new to your company, new to your industry, new to world. If the buckets are too big, jettison some newness, and if there’s something in the new-to-world bucket, be careful.

Create test protocols (how you’ll test) and minimum acceptance criteria (specification limits) before doing design work. It’s a great way to create clarity.

Build first – build the crudest possible prototype to expose the unfamiliar, and use the learning to shape the next prototypes and to focus analyses. Do this until you run out of time.

Cost and function are joined at the hip, so measure engineering on both.

Have a healthy dissatisfaction for success. Recognize success, yes, but also recognize it’s fleeting. Someone will obsolete your success, and it should be you.

To get an engineering team to believe in themselves, you must believe in them. To believe in them, you must believe in yourself.

Circle of Life

Engineers solve technical problems so

Other engineers can create products so

Companies can manufacture them so

They can sell them for a profit and

Use the wealth to pay workers so

Workers can support their families and pay taxes so

Their countries have wealth for good schools to

Grow the next generation of engineers to

Solve the next generation of technical problems so…

More Risk, Less Consequence

WHY? To grow sales in existing markets and create sales in new markets.

WHY? To grow sales in existing markets and create sales in new markets.

WHAT? Create innovative technologies and design products with more function and less cost.

HOW? Educate the engineering engine.

This is easier said than done, because for years we’ve set one-sided expectations – new products must work and timelines must be met – and driven risk tolerance out of our engineering engine. Now it’s time to inject it back in.

The message – Our thinking must change. We must take more risk, but do it safely by reducing negative consequences of risk.

To reduce negative consequences of risk, we must learn to localize risk through the narrowest and deepest problem definition, and learn to secure the launch so it’s safe to try new things.

We must do more up-front technology work, but learn to do it far more narrowly and deeply. We must learn to hold ourselves accountable to rigorous problem definition, and we must put our best people on technology projects.

To focus creativity we must learn to set seemingly unrealistic time constraints; to focus our actions we can look to a powerful mantra – spend a little, learn a lot.

The trouble with new thinking is it takes new thinking. If you don’t have it, go get it. If you already have it, figure out why you haven’t used it.

You might be a superhero if…

- Using just dirt, rocks, and sticks, you can bring to life a product that makes life better for society.

- Using just your mind, you can radically simplify the factory by changing the product itself.

- Using your analytical skills, you can increase product function in ways that reinvent your industry.

- Using your knowledge of physics, you can solve a longstanding manufacturing problem by making a product insensitive to variation.

- Using your knowledge of Design for Manufacturing and Assembly, you can reduce product cost by 50%.

- Using your knowledge of materials, you can eliminate a fundamental factory bottleneck by changing what the product is made from.

- Using your curiosity and creativity, you can invent and commercialize a product that creates a new industry.

- Using your superpowers, you think you can fix a country’s economy one company at a time.

Win Hearts and Minds

As an engineering leader you have the biggest profit lever in the company. You lead the engineering teams, and the engineering teams design the products. You can shape their work, you can help them raise their game, and you can help them change their thinking. But if you don’t win their hearts and minds, you have nothing.

As an engineering leader you have the biggest profit lever in the company. You lead the engineering teams, and the engineering teams design the products. You can shape their work, you can help them raise their game, and you can help them change their thinking. But if you don’t win their hearts and minds, you have nothing.

Engineers must see your intentions are good, you must say what you do and do what you say, and you must be in it for the long haul. And over time, as they trust, the profit lever grows into effectiveness. But if you don’t earn their trust, you have nothing.

But even with trust, you must be light on the tiller. Engineers don’t like change (we’re risk reducing beings), but change is a must. But go too quickly, and you’ll go too slowly. You must balance praise of success with praise of new thinking and create a standing-on-the-shoulders-of-giants mindset. But this is a challenge because they are the giants – you’re asking them to stand on their own shoulders.

How do you know they’re ready for new thinking? They’re ready when they’re willing to obsolete their best work and to change their work to make it happen. Strangely, they don’t need to believe it’s possible – they only need to believe in you.

Now the tough part: There’s a lot of new thinking out there. Which to choose?

Whatever the new thinking, it must make sense at a visceral level, and it must be simple. (But not simplistic.) Don’t worry if you don’t yet have your new thinking; it will come. As a seed, here are my top three new thinkings:

Define the problem. This one cuts across everything we do, yet most underwhelm it. To get there, ask your engineers to define their problems on one page. (Not five, one.) Ask them to use sketches, cartoons, block diagram, arrows, and simple nouns and verbs. When they explain the problem on one page, they understand the problem. When they need two, they don’t.

Test to failure. This one’s subtle but powerful. Test to define product limits, and don’t stop until it breaks. No failure, no learning. To get there, resurrect the venerable test-break-fix cycle and do it until you run out of time (product launch.) Break the old product, test-break-fix the new product until it’s better.

Simplify the product. This is where the money is. Product complexity drives organizational complexity – simplify the product and simply everything. To get there, set a goal for 50% part count reduction, train on Design for Assembly (DFA), and ask engineering for part count data at every design review.

I challenge you to challenge yourself: I challenge you to define new thinking; I challenge you to help them with it; I challenge you to win their hearts and minds.

Mike Shipulski

Mike Shipulski