Archive for the ‘Green’ Category

Where is petroleum consumed?

In last week’s post, I provided a chart that describes the sources of electricity for the United States. Coal is the largest source of electricity (38%) and natural gas is the next largest (25%). The largest non-carbon source is nuclear (22%) and the largest renewable sources are wind (6%) and solar (5%). The data from the chart came from Otherlab who was contracted by the Advanced Research Project Agency of the Department of Energy (ARPA-e) to review all available energy data sources and create an ultra-high resolution picture of the U.S. energy economy.

In last week’s post, I provided a chart that describes the sources of electricity for the United States. Coal is the largest source of electricity (38%) and natural gas is the next largest (25%). The largest non-carbon source is nuclear (22%) and the largest renewable sources are wind (6%) and solar (5%). The data from the chart came from Otherlab who was contracted by the Advanced Research Project Agency of the Department of Energy (ARPA-e) to review all available energy data sources and create an ultra-high resolution picture of the U.S. energy economy.

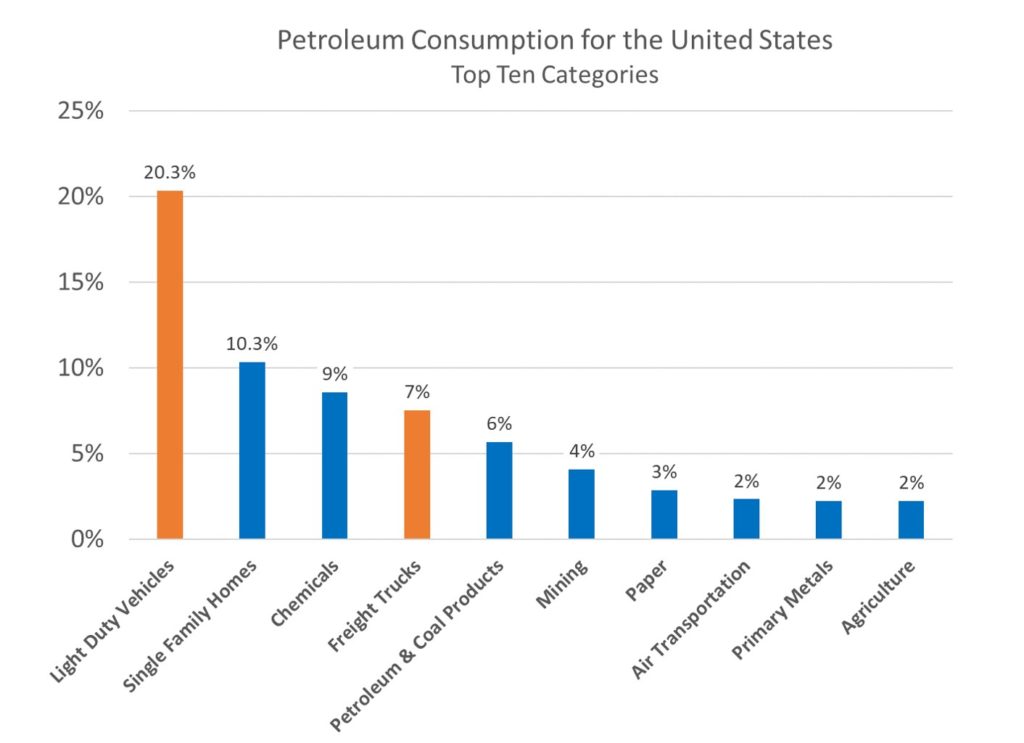

Using the same data set, I created a chart to break out the top ten categories for petroleum consumption for the United States.

The category Light-Duty Vehicles (cars, light trucks) is the largest consumer at 20% and is more than the sum of the next two categories – Single-Family Homes (10%) and Chemicals (9%).

When Light-Duty Vehicles at 20% are combined with Freight Trucks (think eighteen-wheelers) at 7%, they make up 27% of the country’s total consumption, making the Transportation sector the thirstiest. The most effective way to reduce petroleum consumption is to replace vehicles powered by internal combustion engines with electric vehicles (EVs). But there’s a catch.

As internal combustion engines diminish and EVs come online, petroleum consumption will drop and will help the planet. But, as EVs come online the demand for electricity will increase, making it even more important to replace coal and natural gas with zero-carbon sources of electricity: nuclear, hydro, wind and solar.

To save the planet, here’s what you can do. Vote for political candidates who will end federal subsidies for coal and natural gas. That single change will accelerate the adoption of wind and solar, as it will increase the existing cost advantage of wind and solar. And if that freed-up money can be reallocated to federally-funded R&D to improve the controllability of electrical grids, the change will come even sooner.

And at the state and local level, you can vote for candidates that want to make it easier for wind and solar projects to be funded.

And, lastly, you can buy an EV. You will see a much larger selection of new electric vehicles over the next year and the driving range continues to improve. Over the next year, most new EV models will be high performance and high cost, lower-cost EVs should follow soon after.

Image credit – NASA Goodard Flight Center

It’s All Connected

There’s a natural tendency to simplify, to reduce, to narrow. In the name of problem solving, it’s narrow the scope, break it into small bites, and don’t worry about the subtle complexities. And for a lot of situations that works. But after years of fixing things one bite at a time, there are fewer and fewer situations that fit the divide and conquer approach. (Actually, they’re still there, but their return on investment is super low.) And after years of serial discretization, what are left are situations that cannot be broken up, that cut across interfaces, that make up a continuum. What are left are big problems and big situations that have huge payoff if solved, but are interconnected.

There’s a natural tendency to simplify, to reduce, to narrow. In the name of problem solving, it’s narrow the scope, break it into small bites, and don’t worry about the subtle complexities. And for a lot of situations that works. But after years of fixing things one bite at a time, there are fewer and fewer situations that fit the divide and conquer approach. (Actually, they’re still there, but their return on investment is super low.) And after years of serial discretization, what are left are situations that cannot be broken up, that cut across interfaces, that make up a continuum. What are left are big problems and big situations that have huge payoff if solved, but are interconnected.

Whether it’s cross-discipline, cross-organization, cross-cultural, or cross-best practice, the fundamental of these big kahunas is they cross interfaces. And that’s why they’ve never been attacked, and that’s why they’ve never been solved. But with payoffs so big, it’s time to take on connectedness.

For me, the most severe example of connectedness is woven around the product. To commercialize a product there are countless business process that cut across almost every interface. Here are a few: innovation, technology development, product development, robustness testing, product documentation, manufacturing engineering, marketing, sales, and service. Each of these processes is led by one organization and cuts across many; each cut across expertise-specialization interfaces; each requires information and knowledge from the other; and each new product development project must cooperate with all the others. They cannot be separated or broken into bits. Change one with intent and change the others with unintended consequences. No doubt – they’re connected.

Green thinking is much overdue, but with it comes connectedness squared. With pre-green product commercialization, the product flowed to the end user and that was about it. But with environmental movement there’s a whole new return path of interconnected business processes. Green thinking has turned the product life cycle into the circle of life – the product leaves, it lives it’s life, and it always comes back home.

And with this return path of connectedness, how the product goes together in manufacturing must be defined in conjunction with how it will be disassembled and recycled. Stress analysis must be coordinated with packaging design, regulations of banned substances, and material reuse of retired product. Marketing literature must be co-produced with regulatory strategy and recycling technologies. It’s connected more than ever.

But the bad news is the good news. Yes, things are more interwoven and the spider web is more tangled. But the upside – companies that can manage the complexity will have a significant advantage. Those that can navigate within connectedness will win.

The first step is to admit there’s a problem, and before connectedness can be managed, it must be recognized. And before it can become competitive advantage, it must be embraced.

Amplify The Social Benefits of Your Products

To do g ood for the planet and make lots of money (or the other way around), I think companies should shift from an economic framework to a social one. Green products are a good example. Facts are facts: today, as we define cost, green products cost more; burning fossil fuel is the lowest cost way to produce electricity and move stuff around (people, products, raw material). Green products are more expensive and do less, yet they sell. But the economic benefits don’t sell, the social ones do. Lower performance and higher costs of green products should be viewed not as weaknesses, but as strengths.

ood for the planet and make lots of money (or the other way around), I think companies should shift from an economic framework to a social one. Green products are a good example. Facts are facts: today, as we define cost, green products cost more; burning fossil fuel is the lowest cost way to produce electricity and move stuff around (people, products, raw material). Green products are more expensive and do less, yet they sell. But the economic benefits don’t sell, the social ones do. Lower performance and higher costs of green products should be viewed not as weaknesses, but as strengths.

Green technologies are immature and expensive, but there’s no questions they’re the future. Green products will create new markets, and companies that create new markets will dominate them. The first sales of expensive green products are made by those who can afford them; they put their money where their mouths are and pay more for less to make a social statement. In that way, the shortcoming of the product amplifies the social statement. It’s clear the product was purchased for the good of others, not solely for the goodness of the product itself. The sentiment goes like this: This product is more expensive, but I think the planet is worth my investment. I’m going to buy, and feel good doing it.

The Prius is a good example. While its environmental benefits can be debated, it clearly does not drive as well as other cars (handling, acceleration, breaking). Yet people buy them. People buy them because that funny shape is mapped to a social statement: I care about the environment. Prius generates a signal: I care enough about the planet to put my money where my mouth is. It’s a social statement. I propose companies use a similar social framework to create new markets with green products that do less, cost more, and overtly signal their undeniable social benefit. (To be clear, the product should undeniably make the planet happy.)

The company that creates a new market owns it. (At least it’s theirs to lose). Early sales impregnate the brand with the green product’s important social statement, and the new market becomes the brand and its social statement. And more than that, early sales enable the company to work out the bugs, allow the technology to mature, and yield lower costs. Lower costs enable a cost effective market build-out.

Don’t shy away from performance gaps of green technologies, embrace them; acknowledge them to amplify the social benefit. Don’t shy away from a high price, embrace it; acknowledge the investment to amplify the social benefit. Be truthful about performance gaps, price it high, and proudly do good for the planet.

Make your green programs actionable

There’s a big push to be green. Though we want to be green, we’re not sure how to get there. We’ve got high-level metrics, but they’re not actionable. It’s time to figure out what we can change to be green.

There’s a big push to be green. Though we want to be green, we’re not sure how to get there. We’ve got high-level metrics, but they’re not actionable. It’s time to figure out what we can change to be green.

One way manufacturers can be green is to reduce their carbon footprint. That’s one level deeper than simply “being green,” but it’s not actionable either. Digging deeper, manufacturers can reduce their carbon footprint by generating less greenhouse gases, specifically carbon dioxide. Reducing carbon dioxide production is a good goal, but it’s still not actionable.

Looking deeper, carbon dioxide is the result of burning fossil fuels,

Want to be green? Look to your product.

We’re starting to come to terms with the green revolution; we’re staring to realize that green is good for our planet and even better for our business. But how do we put greenwashing behind us and truly make a difference?

We’re starting to come to terms with the green revolution; we’re staring to realize that green is good for our planet and even better for our business. But how do we put greenwashing behind us and truly make a difference?

To improve recyling, find the non-recyclable stuff in your product and design it out. Make a Pareto chart of non-recyclable stuff (by weight) by major subassembly, and focus the design effort on the biggest brown bars of the Pareto. (Consider packaging a major subassembly and give it its own bar.)

To improve carbon footprint of logistics, find the weight and volume of your product and design out the biggest and heaviest. Make a Pareto chart of weight by major subassembly, and focus the design effort on the heaviest brown bars. Make a Pareto chart of volume by major subassembly, (Make cube around the subassembly and calculate volume in mm3.) and focus the design effort on the biggest bars. (Don’t forget the packaging.)

To improve energy efficiency of your factory, find electricity consumption and design it out. Make a Pareto chart of electricity consumption by major process step then map it to the product – to the element of the product that creates the need for electricity, and focus the design effort on the biggest bars.

Going forward, here are some thoughts to help grow your business with green (and save the planet):

- It’s easier to design out brown than to design in green.

- To design out brown, you’ve got to know where it is.

- The product creates brown – look to the product to eliminate it.

Mike Shipulski

Mike Shipulski