Posts Tagged ‘Design Alternatives’

Incomplete Definition – A Way Of Life

At the start of projects, no one knows what to do. Engineering complains the specification isn’t fully defined so they cannot start, and marketing returns fire with their complaint – they don’t yet fully understand the customer needs, can’t lock down the product requirements, and need more time. Marketing wants to keep things flexible and engineering wants to lock things down; and the result is a lot of thrashing and flailing and not nearly enough starting.

At the start of projects, no one knows what to do. Engineering complains the specification isn’t fully defined so they cannot start, and marketing returns fire with their complaint – they don’t yet fully understand the customer needs, can’t lock down the product requirements, and need more time. Marketing wants to keep things flexible and engineering wants to lock things down; and the result is a lot of thrashing and flailing and not nearly enough starting.

Both camps are right – the spec is only partially formed and customer needs are only partially understood – but the project must start anyway. But the situation isn’t as bad as it seems. At the start of a project fully wrung out specs and fully validated customer needs aren’t needed. What’s needed is definition of product attributes that set its character, definition of how those attributes will be measured, and definition of the competitive products. The actual values of the performance attributes aren’t needed, just their name, their relative magnitude expressed as percent improvement, and how they’ll be measured.

And to do this the project manager asks the engineering and marketing groups to work together to create simple bar charts for the most important product attributes and then schedules the meeting where the group jointly presents their single set of bar charts.

This little trick is more powerful than it seems. In order to choose competitive products, a high level characterization of the product must be roughed out; and once chosen they paint a picture of the landscape and set the context for the new product. And in order to choose the most important performance (or design) attributes, there must be convergence on why customers will buy it; and once chosen they set the context for the required design work.

Here’s an example. Audi wants to start developing a new car. The marketing-engineering team is tasked to identify the competitive products. If the competitive products are BMW 7 series, Mercedes S class, and the new monster Hyundai, the character of the new car and the character of the project are pretty clear. If the competitive products are Ford Focus, Fiat F500, and Mini Cooper, that’s a different project altogether. For both projects the team doesn’t know every specification, but it knows enough to start. And once the competitive products are defined, the key performance attributes can be selected rather easily.

But the last part is the hardest – to define how the performance characteristics will be measured, right down to the test protocols and test equipment. For the new Audi fuel economy will be measured using both the European and North American drive cycles and measured in liters per 100 kilometer and miles per gallon (using a pre-defined fuel with an 89 octane rating); interior noise will be measured in six defined locations using sound meter XYZ and expressed in decibels; and overall performance will be measured by the lap time around the Nuremburg Ring under full daylight, dry conditions, and 25 Centigrade ambient temperature, measured in minutes.

Bar charts are created with the names of the competitive vehicles (and the new Audi) below each bar and performance attribute (and units, e.g., miles per gallon) on the right. Side-by-side, it’s pretty clear how the new car must perform. Though the exact number is not know, there’s enough to get started.

At the start of a project the objective is to make sure you’re focusing on the most performance attributes and to create clarity on how the attributes (and therefore the product) will be measured. There’s nothing worse than spending engineering resources in the wrong area. And it’s doubly bad if your misplaced efforts actually create constraints that limit or reduce performance of the most important attributes. And that’s what’s to be avoided.

As the project progresses, marketing converges on a detailed understanding of customer needs, and engineering converges on a complete set of specifications. But at the start, everything is incomplete and no part of the project is completely nailed down.

The trick is to define the most important things as clearly as possible, and start.

Assess Design Alternatives With Axiomatic Design

Al Hamilton, of Axiomatic Design Solutions, wrote a good article on how Axiomatic Design can be used to evaluate multiple design alternatives.

Here is an excerpt from the article:

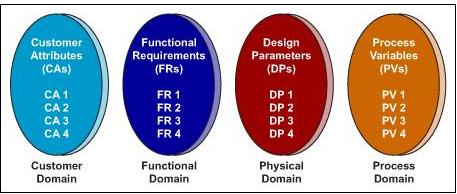

Axiomatic design breaks the design process into four domains, shown in Figure 1. The customer domain can be thought of as the voice of the customer (VOC).

- The functional domain is initially populated by mapping the VOC into independent measurable functions. High-level functions are driven by the customer; lower-level functions are driven by design choices. Every function must be measurable.

- The physical domain is the domain of physics, chemistry, math and algorithms.

- The process domain is where the specifics of how the design parameters identified in the physical domain will be implemented.

Dr. Mike Shipulski, director of engineering at Hypertherm, a manufacturer of plasma cutting systems, has made extensive use of axiomatic design. Shipulski observes, “By first defining the functions we are to achieve, we align our problem solving on the right areas and broaden possible design opportunities. With axiomatic design, we have a framework for avoiding problems that are often detected only during system-level testing.”

Mike Shipulski

Mike Shipulski