Archive for the ‘DFMA’ Category

It’s not so easy to move manufacturing work back to the US.

I hear it’s a good idea to move manufacturing work back to the US.

Before getting into what it would take to move manufacturing work back to the US, I think it’s important to understand why manufacturing companies moved their work out of the US. Simply put, companies moved their work out of the US because their accounting systems told them they would make more money if they made their products in countries with lower labor costs. And now that labor costs have increased in these no longer “low-cost countries”, those same accounting systems think there’s more money to be made by bringing manufacturing back to the US.

At a low level of abstraction, manufacturing, as a word, is about making discrete parts like gears, fenders, and tires using machines like gear shapers, stamping machines, and injection molding machines. The cost of manufacturing the parts is defined by the cost of the raw material, the cost of the machines, the cost of energy to power the machines, the cost of the factory, and the cost of the people to run the machines. And then there’s assembly, which, as a word, is about putting those discrete parts together to make a higher-level product. Where manufacturing makes the gears, fenders, and tires, assembly puts them together to make a car. And the cost of assembly is defined by the cost of the factory, the cost of fixtures, and the cost of the people to assemble the parts into the product. And the cost of the finished product is the sum of the cost of making the parts (manufacturing) and the cost of putting them together (assembly).

It seems pretty straightforward to make more money by moving the manufacturing of discrete parts back to the US. All that has to happen is to find some empty factory space, buy new machines, land them in the factory, hire the people to run the machines, train them, source the raw material, hire the manufacturing experts to reinvent/automate the manufacturing process to reduce cycle time and reduce labor time and then give them six months to a year to do that deep manufacturing work. That’s quite a list because there’s little factory space available that’s ready to receive machines, the machines cost money, there are few people available to do manufacturing work, the cost to train them is high (and it takes time and there are no trained trainers). But the real hurdles are the deep work required to reinvent/automate the process and the lack of manufacturing experts to do that work. The question you should ask is – Why does the manufacturing process have to be reinvented/automated?

There’s a dirty little secret baked into the accounting systems’ calculations. The cost accounting says there can be no increased profit without reducing the time to make the parts and reducing the labor needed to make them. If the work is moved from country A to country B and the costs (cycle time, labor hours, labor rate) remain constant, the profit remains constant. Simply moving from country A to country B does nothing. Without the deep manufacturing work, profits don’t increase. And if your country doesn’t have the people with the right expertise, that deep manufacturing work cannot happen.

And the picture is similar for moving assembly work back to the US. All that has to happen is to find empty factory space, hire and train people to do the assembly work, reroute the supply chains to the new factory, redesign the product so it can be assembled with an automated assembly line, hire/train the people to redesign the product so it can be assembled in an automated way, design the new automated assembly process, build it, test it, hire/train the automated assembly experts to do that work, hire the people to support and run the automated assembly line, and pay for the multi-million-dollar automated assembly line. And the problems are similar. There’s not a lot of world-class factory space, there are few people available to run the automated assembly line, and the cost of the automated assembly line is significant. But the real problems are the lack of experts to redesign the product for automated assembly and the lack of expertise to design, build, and validate the assembly line. And here are the questions you should ask – Why do we need to automate the assembly process and why does the product have to be redesigned to do that?

It’s that dirty little secret rearing its ugly head again. The cost accounting says there can be no increased profit without reducing the labor to assemble the parts. make them. If the work is moved from country A to country B and the assembly costs (labor hours, labor rate) remain constant, the profit remains constant. Simply moving from country A to country B does nothing. Without deep design work (design for automated assembly) and ultra-deep automated assembly work, profits don’t increase. And if your country doesn’t have the people with the right expertise, that deep design and automated assembly work cannot happen.

If your company doesn’t have the time, money, and capability to reinvent/automate manufacturing processes, it’s a bad idea to move manufacturing work back to the US. It simply won’t work. Instead, find experts who can help you develop/secure the capability to reinvent/automate manufacturing processes to reduce the cost of manufacturing.

If your company doesn’t have the time, money, and capability to design products for automated assembly and to design, build, and validated automated assembly systems, it’s a bad idea to move assembly work back to the US. It, too, simply won’t work. Instead, partner with experts who know how to do that work so you can reduce the cost of assembly.

The best time to design cost out of our products is now.

With inflation on the rise and sales on the decline, the time to reduce costs is now.

With inflation on the rise and sales on the decline, the time to reduce costs is now.

But before you can design out the cost you’ve got to know where it is. And the best way to do that is to create a Pareto chart that defines product cost for each subassembly, with the highest cost subassemblies on the left and the lowest cost on the right. Here’s a pro tip – Ignore the subassemblies on the right.

Use your costed Bill of Materials (BOMs) to create the Paretos. You’ll be told that the BOMs are wrong (and they are), but they are right enough to learn where the cost is.

For each of the highest-cost subassemblies, create a lower-level Pareto chat that sorts the cost of each piece-part from highest to lowest. The pro tip applies here, too – Ignore the parts on the right.

Because the design community designed in the cost, they are the ones who must design it out. And to help them prioritize the work, they should be the ones who create the Pareto charts from the BOMs. They won’t like this idea, but tell them they are the only ones who can secure the company’s future profits and buy them lots of pizza.

And when someone demands you reduce labor costs, don’t fall for it. Labor cost is about 5% of the product cost, so reducing it by half doesn’t get you much. Instead, make a Pareto chart of part count by subassembly. Focus the design effort on reducing the part count of subassemblies on the left. Pro tip – Ignore the subassemblies on the right. The labor time to assemble parts that you design out is zero, so when demand returns, you’ll be able to pump out more products without growing the footprint of the factory. But, more importantly, the cost of the parts you design out is also zero. Designing out the parts is the best way to reduce product costs.

Pro tip – Set a cost reduction goal of 35%. And when they complain, increase it to 40%.

In parallel to the design work to reduce part count and costs, design the test fixtures and test protocols you’ll use to make sure the new, lower-cost design outperforms the existing design. Certainly, with fewer parts, the new one will be more reliable. Pro tip – As soon as you can, test the existing design using the new protocols because the only way to know if the new one is better is to measure it against the test results of the old one.

And here’s the last pro tip – Start now.

Image credit — aisletwentytwo

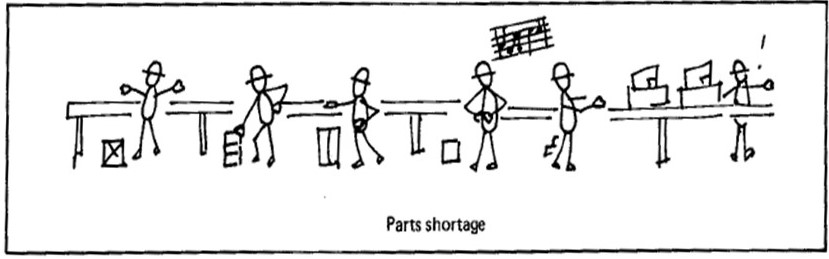

Supply chains don’t have to break.

We’ve heard a lot about long supply chains that have broken down, parts shortages, and long lead times. Granted, supply chains have been stressed, but we’ve designed out any sort of resiliency. Our supply chains are inflexible, our products are intolerant to variation and multiple sources for parts, and our organizations have lost the ability to quickly and effectively redesign the product and the parts to address issues when they arise. We’ve pushed too hard on traditional costing and have not placed any value on flexibility. And we’ve pushed too hard on efficiency and outsourced our design capability so we can no longer design our way out of problems.

We’ve heard a lot about long supply chains that have broken down, parts shortages, and long lead times. Granted, supply chains have been stressed, but we’ve designed out any sort of resiliency. Our supply chains are inflexible, our products are intolerant to variation and multiple sources for parts, and our organizations have lost the ability to quickly and effectively redesign the product and the parts to address issues when they arise. We’ve pushed too hard on traditional costing and have not placed any value on flexibility. And we’ve pushed too hard on efficiency and outsourced our design capability so we can no longer design our way out of problems.

Our supply chains are inflexible because that’s how we designed them. The products cannot handle parts from multiple suppliers because that’s how we designed them. And the parts cannot be made by multiple suppliers because that’s how we designed them.

Now for the upside. If we want a robust supply chain, we can design the product and the parts in a way that makes a robust supply chain possible. If we want the flexibility to use multiple suppliers, we can design the product and parts in a way that makes it possible. And if we want the capability to change the product to adapt to unforeseen changes, we can design our design organizations to make it possible.

There are established tools and methods to help the design community design products in a way that creates flexibility in the supply chain. And those same tools and methods can also help the design community create products that can be made with parts from multiple suppliers. And there are teachers who can help rebuild the design community’s muscles so they can change the product in ways to address unforeseen problems with parts and suppliers.

How much did it cost you when your supply chain dried up? How much did it cost you the last time a supplier couldn’t deliver your parts? How much did it cost you when your design community couldn’t redesign the product to keep the assembly line running? Would you believe me if I told you that all those costs are a result of choices you made about how to design your supply chain, your product, your parts, and your engineering community?

And would you believe me if I told you could make all that go away? Well, even if you don’t believe me, the potential upside of making it go away is so significant you may want to look into it anyway.

Image credit — New Manufacturing Challenge, Suzaki, 1987.

Product Thinking

Product costs, without product thinking, drop 2% per year. With product thinking, product costs fall by 50%, and while your competitors’ profit margins drift downward, yours are too high to track by conventional methods. And your company is known for unending increases in stock price and long term investment in all the things that secure the future.

The supply chain, without product thinking, improves 3% per year. With product thinking, longest lead processes are eliminated, poorest yield processes are a thing of the past, problem suppliers are gone, and your distributers associate your brand with uninterrupted supply and on time delivery.

Product robustness, without product thinking, is the same year-on-year. Re-injecting long forgotten product thinking to simplify the product, product robustness jumps to unattainable levels and warranty costs plummet. And your brand is known for products that simply don’t break.

Rolled throughput yield is stalled at 90%. With product thinking, the product is simplified, opportunities for defects are reduced, and throughput skyrockets due to improved RTY. And your brand is known as a good value – providing good, repeatable functionality at a good price.

Lean, without product thinking has delivered wonderful results, but the low hanging fruit is gone and lean is moving into the back office. With product thinking, the design is changed and value-added work is eliminated along with its associated non-value added work (which is about 8 times bigger); manufacturing monuments with their long changeover times are ripped out and sold to your competitors; work from two factories is consolidated into one; new work is taken on to fill the emptied factories; and profit per square foot triples. And your brand is known for best-in-class quality, unbeatable on time delivery, world class performance, and pioneering the next generation of lean.

The sales argument is low price and good payment terms. With product thinking, the argument starts with product performance and ends with product reliability. The sales team is energized, and your brand is linked with solid products that just plain work.

The marketing approach is stickers and new packaging. With product thinking, it’s based on competitive advantage explained in terms of head-to-head performance data and a richer feature set. And your brand stands for winning technology and killer products.

Product thinking isn’t for everyone. But for those that try – your brand will thank you.

Circle of Life

Engineers solve technical problems so

Other engineers can create products so

Companies can manufacture them so

They can sell them for a profit and

Use the wealth to pay workers so

Workers can support their families and pay taxes so

Their countries have wealth for good schools to

Grow the next generation of engineers to

Solve the next generation of technical problems so…

You might be a superhero if…

- Using just dirt, rocks, and sticks, you can bring to life a product that makes life better for society.

- Using just your mind, you can radically simplify the factory by changing the product itself.

- Using your analytical skills, you can increase product function in ways that reinvent your industry.

- Using your knowledge of physics, you can solve a longstanding manufacturing problem by making a product insensitive to variation.

- Using your knowledge of Design for Manufacturing and Assembly, you can reduce product cost by 50%.

- Using your knowledge of materials, you can eliminate a fundamental factory bottleneck by changing what the product is made from.

- Using your curiosity and creativity, you can invent and commercialize a product that creates a new industry.

- Using your superpowers, you think you can fix a country’s economy one company at a time.

Lean and Supply Chain Sensitivity

At every turn, lean has increased profits in the factory. Its best trick is to look at the work through a time lens, see wasted time, and get rid of it.

At every turn, lean has increased profits in the factory. Its best trick is to look at the work through a time lens, see wasted time, and get rid of it.

Work is blocked by problems. You watch the work to spot blockages in the form of piles, otherwise known as inventory. When you find a pile, you know the problem is one operation downstream.

As lean works its magic, inventory is reduced, which decreases carrying costs. More importantly, however, it also reduces the time to see a problem. Whether the problem is related to quality, delivery or resources, everything stops immediately. It’s clear what to fix, and there’s incentive to fix it quickly because with lean, the factory is more sensitive to problems.

What works in the factory will also work in the supply chain, and that’s where lean is going.

A Recipe for Unreasonable Profits

There’s an unnatural attraction to lean – a methodology to change the value stream to reduce waste. And it’s the same with Design for Manufacturing (DFM) – a methodology to design out cost of your piece-parts. The real rain maker is Design for Assembly (DFA) which eliminates parts altogether (50% reductions are commonplace.) DFA is far more powerful.

There’s an unnatural attraction to lean – a methodology to change the value stream to reduce waste. And it’s the same with Design for Manufacturing (DFM) – a methodology to design out cost of your piece-parts. The real rain maker is Design for Assembly (DFA) which eliminates parts altogether (50% reductions are commonplace.) DFA is far more powerful.

The cost for a designed out part is zero. Floor space for a designed out part is zero. Transportation cost for a designed out part is zero. (Can you say Green?) From a lean perspective, for a designed out part there is zero waste. For a designed out part the seven wastes do not apply.

Here’s a recipe for unreasonable profits:

Design out half the parts with DFA. For the ones that remain, choose the three highest cost parts and design out the cost. Then, and only then, do lean on the manufacturing processes.

For a video version of the post, see this link: (Video embedded below.)

A Recipe for Unreasonable Profits.

How To Create a Sea of Manufacturing Jobs

It’s been a long slide from greatness for US manufacturing. It’s been downhill since the 70s – a multi-decade slide. Lately there’s a lot of hype about a manufacturing renaissance in the US – re-shoring, on-shoring, right-shoring. But the celebration misguided. A real, sustainable return to greatness will take decades, decades of single-minded focus, coordination, alignment and hard work – industry, government, and academia in it together for the long haul.

It’s been a long slide from greatness for US manufacturing. It’s been downhill since the 70s – a multi-decade slide. Lately there’s a lot of hype about a manufacturing renaissance in the US – re-shoring, on-shoring, right-shoring. But the celebration misguided. A real, sustainable return to greatness will take decades, decades of single-minded focus, coordination, alignment and hard work – industry, government, and academia in it together for the long haul.

To return to greatness, the number of new manufacturing jobs to be created is distressing. 100,000 new manufacturing jobs is paltry. And today there is a severe skills gap. Today there are unfilled manufacturing jobs because there’s no one to do the work. No one has the skills. With so many without jobs it sad. No, it’s a shame. And the manufacturing talent pipeline is dry – priming before filling. Creating a sea of new manufacturing jobs will be hard, but filling them will be harder. What can we do?

The first thing to do is make list of all the open manufacturing jobs and categorize them. Sort them by themes: by discipline, skills, experience, tools. Use the themes to create training programs, train people, and fill the open jobs. (Demonstrate coordinated work of government, industry, and academia.) Then, using the learning, repeat. Define themes of open manufacturing jobs, create training programs, train, and fill the jobs. After doing this several times there will be sufficient knowledge to predict needed skills and proactive training can begin. This cycle should continue for decades.

Now the tough parts – transcending our short time horizon and finding the money. Our time horizon is limited to the presidential election cycle – four years, but the manufacturing rebirth will take decades. Our four year time horizon prevents success. There needs to be a guiding force that maintains consistency of purpose – manufacturing resurgence – a consistency of purpose for decades. And the resurgence cannot require additional money. (There isn’t any.) So who has a long time horizon and money?

The DoD has both – the long term view (the military is not elected or appointed) and the money. (They buy a lot of stuff.) Before you call me a war hawk, this is simply a marriage of convenience. I wish there was, but there is no better option.

The DoD should pull together their biggest contractors (industry) and decree that the stuff they buy will have radically reduced cost signatures and teach them and their sub-tier folks how to get it done. No cost reduction, no contract. (There’s no reason military stuff should cost what it does, other than the DoD contractors don’t know how design things cost effectively.) The DoD should educate their contractors how to design products to reduce material cost, assembly time, supply chain complexity, and time to market and demand the suppliers. Then, demand they demonstrate the learning by designing the next generation stuff. (We mistakenly limit manufacturing to making, when, in fact, radical improvement is realized when we see manufacturing as designing and making.)

The DoD should increase its applied research at the expense of its basic research. They should fund applied research that solves real problems that result in reduced cost signatures, reduce total cost of ownership, and improved performance. Likely, they should fund technologies to improve engineering tools, technologies that make themselves energy independent and new materials. Once used in production-grade systems, the new technologies will spill into non-DoD world (broad industry application) and create new generation products and a sea of manufacturing jobs.

I think this is approach has a balanced time horizon – fill manufacturing jobs now and do the long term work to create millions of manufacturing jobs in the future.

Yes, the DoD is at the center of the approach. Yes, some have a problem with that. Yes, it’s a marriage of convenience. Yes, it requires coordination among DoD, industry, and academia. Yes, that’s almost impossible to imagine. Yes, it requires consistency of purpose over decades. And, yes, it’s the best way I know.

What is Design for Manufacturing and Assembly?

Design for Manufacturing (DFM) is all about reducing the cost of piece-parts. Design for Assembly is all about reducing the cost of putting things together (assembly). What’s often forgotten is that function comes first. Change the design to reduce part cost, but make sure the product functions well. Change the parts (eliminate them) to reduce assembly cost, but make sure the product functions well.

Paradoxically, DFM and DFA are all about function.

Here’s a link to a short video that explains DFM and DFA: link to video. (and embedded below)

Engineering’s Contribution to the Profit Equation

We all want to increase profits, but sometimes we get caught in the details and miss the big picture:

We all want to increase profits, but sometimes we get caught in the details and miss the big picture:

Profit = (Price – Cost) x Volume.

It’s a simple formula, but it provides a framework to focus on fundamentals. While all parts of the organization contribute to profit in their own way, engineering’s work has a surprisingly broad impact on the equation.

The market sets price, but engineering creates function, and improved function increases the price the market will pay. Design the product to do more, and do it better, and customers will pay more. What’s missing for engineering is an objective measure of what is good to the customer.

Mike Shipulski

Mike Shipulski