Archive for the ‘Top Line Growth’ Category

Working In Domains of High Uncertainty

X: When will you be done with the project?

X: When will you be done with the project?

Me: This work has never been done before, so I don’t know.

X: But the Leadership Team just asked me when the project will be done. So, what should I say?

Me: Since nothing has changed since the last time you asked me, I still don’t know. Tell them I don’t know.

X: They won’t like that answer.

Me: They may not like the answer, but it’s the truth. And I like telling the truth.

X: Well, what are the steps you’ll take to complete the project?

Me: All I can tell you is what we’re trying to learn right now.

X: So all you can tell me is the work you’re doing right now?

Me: Yes.

X: It seems like you don’t know what you’re doing.

Me: I know what we’re doing right now.

X: But you don’t know what’s next?

Me: How could I? If this current experiment goes up in smoke, the next thing we’ll do is start a different project. And if the experiment works, we’ll do the next right thing.

X: So the project could end tomorrow?

Me: That’s right.

X: Or it could go on for a long time?

Me: That’s right too.

X: Are you always like this?

Me: Yes, I am always truthful.

X: I don’t like your answers. Maybe we should find someone else to run the project.

Me: That’s up to you. But if the new person tells you they know when the project will be done, they’re the wrong person to run the project. Any date they give you will be a guess. And I would not want to be the one to deliver a date like that to the Leadership Team.

X: We planned for the project to be done by the end of the year with incremental revenue starting in the first quarter of next year.

Me: Well, the project work is not bound by the revenue plan. It’s the other way around.

X: So, you don’t care about the profitability of the company?

Me: Of course I care. That’s why we chose this project – to provide novel customer value and sell more products.

X: So the project is intended to deliver new value to our customers?

Me: Yes, that’s how the project was justified. We started with an important problem that, if solved, would make them more profitable.

X: So you’re not just playing around in the lab.

Me: No, we’re trying to solve a customer problem as fast as we can. It only looks like we’re playing around.

X: If it works, would our company be more profitable?

Me: Absolutely.

X: Well, how can I help?

Me: Please meet with the Leadership Team and thank them for trusting us with this important project. And tell them we’re working as fast as we can.

Image credit – Florida Fish and Wildlife

X: Me: format stolen from Simon Wardley (@swardley). Thank you, Simon.

Too Much of a Good Thing

Product cost reduction is a good thing.

Product cost reduction is a good thing.

Too much focus on product cost reduction prevents product enhancements, blocks new customer value propositions, and stifles top-line growth.

Voice of the Customer (VOC) activities are good.

Because customers don’t know what’s possible, too much focus on VOC silences the Voice of the Technology (VOT), blocks new technologies, and prevents novel value propositions. Just because customers aren’t asking for it doesn’t mean they won’t love it when you offer it to them.

Standard work is highly effective and highly productive.

When your whole company is focused on standard work, novelty is squelched, new ideas are scuttled, and new customer value never sees the light of day.

Best practices are highly effective and highly productive.

When your whole company defaults to best practices, novel projects are deselected, risk is radically reduced (which is super risky), people are afraid to try new things and use their judgment, new products are just like the old ones (no sizzle), and top-line growth is gifted to your competitors.

Consensus-based decision-making reduces bad decisions.

In domains of high uncertainty, consensus-based decision-making reduces projects to the lowest common denominator, outlaws the use of judgment and intuition, slows things to a crawl, and makes your most creative people leave the company.

Contrary to Mae West’s maxim, too much of a good thing isn’t always wonderful.

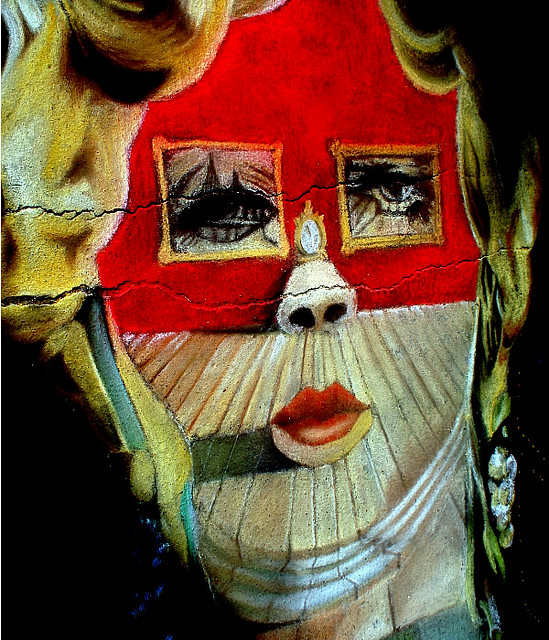

Image credit — Krassy Can Do It

The Next Evolution of Your Success

New ways to work are new because they have not been done before.

New ways to work are new because they have not been done before.

How many new ways to work have you demonstrated over the last year?

New customer value is new when it has not been shown before.

What new customer value have you demonstrated over the last year?

New ways to deliver customer value are new when you have not done it that way before.

How much customer value have you demonstrated through non-product solutions?

The success of old ways of working block new ways.

How many new ways to work have been blocked by your success?

The success of old customer value blocks new customer value.

How much new customer value has been blocked by your success with old customer value?

The success of tried and true ways to deliver customer value blocks new ways to deliver customer value.

Which new ways to deliver unique customer value have been blocked by your success?

Might you be more successful if you stop blocking yourself with your success?

How might you put your success behind you and create the next evolution of your success?

Image credit — Andy Morffew

If you want to change things, do a demo.

When you demo something new, you make the technology real. No longer can they say – that’s not possible.

When you demo something new, you make the technology real. No longer can they say – that’s not possible.

When you demo something new, you help people see what it is and what it isn’t. And that brings clarity.

When you demo something new, people take sides. And that says a lot about them.

When you demo something new, be prepared to demo it again. It takes time for people to internalize new concepts.

When someone asks you to repeat the demo so others can see it, it’s a sign there’s something interesting about the demo. Repeat it.

When someone calls out fault with a minor element of the demo, they also reinforce the strength of the main elements.

When you demo something new and it works perfectly, you should have demo’d it sooner.

When the demo works perfectly, you’re not trying hard enough.

When you demo something new, there is no way to predict the action items spawned by the demo. In fact, the reason to do the demo is to learn the next action items.

When you demo something new, make the demo short so the conversation can be long.

When you demo something new, shut your mouth and let the demo do the talking.

When you demo something new, keep track of the questions that arise. Those questions will inform the next demo.

When you demo something new and it’s misunderstood, congratulations. You’ve helped the audience loosen their thinking.

If you want to change people’s thinking, do a demo.

Image credit – Ralf Steinberger

Overcoming Not Invented Here (NIH), The Most Powerful Blocker of Innovation

When new ideas come from the outside, they are dismissed out of hand. The technical term for this behavior is Not Invented Here (NIH). Because it was not invented by the party with official responsibility, that party stomps it into dust. But NIH doesn’t stomp in public; it stomps in mysterious ways.

When new ideas come from the outside, they are dismissed out of hand. The technical term for this behavior is Not Invented Here (NIH). Because it was not invented by the party with official responsibility, that party stomps it into dust. But NIH doesn’t stomp in public; it stomps in mysterious ways.

Wow! That’s a great idea! Then, mysteriously, no progress is made and it dies a slow death.

That’s cool! Then there’s a really good reason why it can’t be worked.

That’s interesting! Then that morphs into the kiss of death.

We never thought of that. But it won’t scale.

That’s novel! But no one is asking for it.

That’s terribly exciting! We’ll study it into submission.

That’s incredibly different! And likely too different.

When the company’s novel ideas die on the vine, they likely die at the hands of NIH. If you can’t understand why a novel idea never made it out of the lab, investigate the crime scene and you may find NIH’s fingerprints. If customers liked the new idea yet it went nowhere, it could be NIH was behind the crime. If it makes sense, but it doesn’t make progress, NIH is the prime suspect.

If a team is not receptive to novel ideas from the outside, it’s because they consider their own ideas sufficiently good to meet their goals. Things are going well and there’s no reason to adopt new ideas from the outside. And buried in this description are the two ways to overcome NIH.

The fastest way to overcome NIH is to help a new idea transition from an idea conceived by someone outside the team to an idea created by someone inside the team. Here’s how that goes. The idea is first demonstrated by the external team in the form of a functional prototype. This first step aims to help the internal team understand the new idea. Then, the first waiting period is endured where nothing happens. After the waiting period, a somewhat different functional prototype is created by the external team and shown to the internal team. The objective is to help the internal team understand the new idea a little better. Then, the second waiting period is endured where nothing happens. Then, a third functional prototype is created and shown to the internal team. This time, shortcomings are called out by the external team that can only be addressed by the internal team. Then, the last waiting period is endured. Then, after the third waiting period, the internal team addresses the shortcomings and makes the idea their own. NIH is dead, and it’s off to the races.

The second fastest way to overcome NIH is to wait for the internal team to transition to a team that is receptive to new ideas initiated outside the team. The only way for a team to make the transition is for them to realize that their internal ideas are insufficient to meet their objectives. This can only come after their internal ideas are shown to be inadequate multiple times. Only after exhausting all other possibilities, will a team consider ideas generated from outside the team.

When the external team recognizes the internal team is out of ideas, they demonstrate a functional prototype to the internal team. And they do it in an “informational” way, meaning the prototype is investigatory in nature and not intended to become the seed of the internal team’s next generation platform. And as it turns out, it’s only a strange coincidence that the functional prototype is precisely what the internal team needs to fuel the next-generation platform. And the prototype is not fully wrung out. And as it turns out, the parts that need to be wrung out are exactly what the external team knows how to do. And when the internal team needs expertise from the external team to address the novel elements, as it turns out the external team conveniently has the time to help out.

Not Invented Here (NIH) is real. And it’s a powerful force. And it can be overcome. And when it is overcome, the results are spectacular.

Image credit — Becky Mastubara

Bucking The Best Practice

Doing what you did last works well, right up until it doesn’t.

Doing what you did last works well, right up until it doesn’t.

When you put 100% effort into doing what you did last time and get 80% of the output of last time, it’s time to do something different next time.

If it worked last time, but the environment or competition has changed, chances are it won’t work this time.

You can never step in the same river twice, and it’s the same with best practices.

Doing what you did last time is predictable until it isn’t.

The cost of trying the same thing too often is the opportunity cost of unlearned learning, which only comes from doing new things in new ways.

Our accounting systems don’t know how to capture the lost value due to unlearned learning, but your competition does.

Doing what you did last time may be efficient, but that doesn’t matter when it becomes ineffective.

Without new learning, you have a tired business model that will give you less year on year.

If you do what you did last time, you slowly learn what no longer works, but that’s all.

The best practice isn’t best when the context is different.

It’s not okay to do what you did last time all the time.

If you always do what you did last time, you don’t grow as a person.

If you do what you did last time, there are no upside surprises but there may be downside surprises.

Doing what you did last time is bad for your brain and your business.

How much of your work is repeating what you did last time? And how do you feel about that?

If you are tired of doing what you did last time, what are you going to do about it?

Might you sneak in some harmless novelty when no one is looking?

Might you conspire to try something new without raising the suspicion of the Standard Work Police?

Might you run a small experiment where the investment is small but the learning could be important?

Might you propose trying something new in a small way, highlighting the potential benefit and the safe-to-fail nature of the approach?

Might you propose small experiments run in parallel to increase the learning rate?

Might you identify an important problem that has never been solved and try to solve it?

Might you come up with a new solution that radically grows company profits?

Might you create a solution that obsoletes your company’s most profitable offering?

Might you bring your whole self to your work and see what happens?

Image credit – Marc Dalmulder

Projects, Problems and People

The projects you choose define the problems you solve.

The projects you choose define the problems you solve.

The problems you choose to solve define the novel value delivered to the customer.

The people you choose to run the projects set the character of the projects.

The choice of the projects’ character defines how the people feel about working on the projects.

How people choose to feel about working on the projects influences the character of the projects.

The people on the projects choose how the problems are solved.

How people choose to solve problems defines how well the problems are solved.

The choice around how well problems are solved sets the level of goodness delivered to the customer.

The level of goodness you choose to deliver to the customer governs the incremental revenue you create.

It doesn’t seem right that the amount of incremental revenue is a choice.

But, when you choose the right projects and the right people to run them and you choose the right problems and the right people to solve them, incremental revenue becomes your choice.

image credit — officallychaz

You are defined by the problems you solve.

You can solve problems that reduce the material costs of your products.

You can solve problems that reduce the material costs of your products.

You can solve problems that reduce the number of people that work at your company.

You can solve problems that save your company money.

You can solve problems that help your customers make progress.

You can solve problems that make it easier for your customers to buy from you.

You can solve too many small problems and too few big problems.

You can solve problems that ripple profits through your whole organization.

You can solve local problems.

You can solve problems that obsolete your best products.

You can solve problems that extend and defend your existing products.

You can solve problems that spawn new businesses.

You can solve the wrong problems.

You can solve problems before their time or after it is too late.

You can solve problems that change your company or block it from change.

You are defined by the problems you solve. So, which type of problems do you solve and how do you feel about that?

Image credit – Maureen Barlin

The Curse of Too Many Active Projects

If you want your new product development projects to go faster, reduce the number of active projects. Full stop.

If you want your new product development projects to go faster, reduce the number of active projects. Full stop.

A rule to live by: If the new product development project is 90% complete, the company gets 0% of the value. When it comes to new product development projects, there’s no partial credit.

Improving the capabilities of your project managers can help you go faster, but not if you have too many active projects.

If you want to improve the speed of decision-making around the projects, reduce the number of required decisions by reducing the number of active projects.

Resource conflicts increase radically as the number of active projects increases. To fix this, you guessed it, reduce the number of active projects.

A project that is run under the radar is the worst type of active project. It sucks resources from the official projects and prevents truth telling because no one can admit the dark project exists.

With fewer active projects, resource intensity increases, the work is done faster, and the projects launch sooner.

Shared resources serve the projects better and faster when there are fewer active projects.

If you want to go faster, there’s no question about what you should do. You should stop the lesser projects to accelerate the most important ones. Full stop.

And if you want to stop some projects, I suggest you try to answer this question: Why does your company think it’s a good idea to have far too many active new product development projects?

Image credit — JOHN K THORNE

Becoming More Innovative

It’s difficult to describe what an innovative company looks like, and there’s no singular recipe or direction that is right for all companies. Here are some From: To: pairings that I hope will help you in your migration toward innovation. You’re heading in the right direction as your company generates Tos and fewer Froms.

It’s difficult to describe what an innovative company looks like, and there’s no singular recipe or direction that is right for all companies. Here are some From: To: pairings that I hope will help you in your migration toward innovation. You’re heading in the right direction as your company generates Tos and fewer Froms.

From: No one is asking for that technology.

To: What does this new technology stand for?

From: How will the company benefit?

To: How will the customer benefit?

From: What’s the smallest improvement that will make a difference?

To: How can we make the most significant difference?

From: When will you be done?

To: What will you learn?

From: This might not work.

To: How might this work?

From: Start, Start, Continue.

To: Stop, Start, Continue.

From: We’ve tried that before and it didn’t work.

To: What’s changed since last time?

From: What does perfect look like?

To: How is the work done today and which elements can we improve?

From: Defend and Defend the core.

To: Extend and Defend the core.

From: Define the idealized future state.

To: Start with the work.

From: That won’t work!

To: Hey, watch this!

Reducing Time To Market vs. Improving Profits

X: We need to decrease the time to market for our new products.

X: We need to decrease the time to market for our new products.

Me: So, you want to decrease the time it takes to go from an idea to a commercialized product?

X: Yes.

Me: Okay. That’s pretty easy. Here’s my idea. Put some new stickers on the old product and relaunch it. If we change the stickers every month, we can relaunch the product every month. That will reduce the time to market to one month. The metrics will go through the roof and you’ll get promoted.

X: That won’t work. The customers will see right through that and we won’t sell more products and we won’t make more money.

Me: You never said anything about making more money. You said you wanted to reduce the time to market.

X: We want to make more money by reducing time to market.

Me: Hmm. So, you think reducing time to market is the best way to make more money?

X: Yes. Everyone knows that.

Me: Everyone? That’s a lot of people.

X: Are you going to help us make more money by reducing time to market?

Me: I won’t help you with both. If you had to choose between making more money and reducing time to market, which would you choose?

X: Making money, of course.

Me: Well, then why did you start this whole thing by asking me for help improving time to market?

X: I thought it was the best way to make more money.

Me: Can we agree that if we focus on making more money, we have a good chance of making more money?

X: Yes.

Me: Okay. Good. Do you agree we make more money when more customers buy more products from us?

X: Everyone knows that.

Me: Maybe not everyone, but let’s not split hairs because we’re on a roll here. Do you agree we make more money when customers pay more for our products?

X: Of course.

Me: There you have it. All we have to do is get more customers to buy more products and pay a higher price.

X: And you think that will work better than reducing time to market?

Me: Yes.

X: And you know how to do it?

Me: Sure do. We create new products that solve our customers’ most important problems.

X: That’s totally different than reducing time to market.

Me: Thankfully, yes. And far more profitable.

X: Will that also reduce the time to market?

Me: I thought you said you’d choose to make more money over reducing time to market. Why do you ask?

X: Well, my bonus is contingent on reducing time to market.

Me: Listen, if the previous new product development projects took two years, and you reduce the time to market to one and half years, there’s no way for you to decrease time to market by the end of the year to meet your year-end metrics and get your bonus.

X: So, the metrics for my bonus are wrong?

Me: Right.

X: What should I do?

Me: Let’s work together to launch products that solve important customer problems.

X: And what about my bonus?

Me: Let’s not worry about the bonus. Let’s worry about solving important customer problems, and the bonuses will take care of themselves.

Image credit — Quinn Dombrowski

X: Me: format stolen from @swardley. Thank you, Simon.

Mike Shipulski

Mike Shipulski