Posts Tagged ‘Competitiveness’

Going Against The Grain

If you have nothing to say, be the person that doesn’t say it.

If you have nothing to say, be the person that doesn’t say it.

If you’re not the right person to do it, you’re also the right person not to do it. Why is it so difficult for to stop doing what no longer makes sense?

If it made sense to do it last time, it’s not necessarily the right thing to do this time, even if it was successful last time. But if it was successful last time, it will be difficult to do something different this time.

If we always standardize on what we did last time, mustn’t this time always be the same as last time? And musn’t next time always be the same as this time?

If it’s new, it’s scary. And if it’s scary, it’s bad. And we don’t like to get in trouble for doing bad things. And that’s why it’s difficult to do new things.

Deming said to “Drive out fear.” But that’s scary. What are the attributes of the people willing to face the fear and demonstrate that fear can be overcome? At your company are they promoted? Do they stay? Do they leave?

Without someone overcoming their internal fear, there can be no change.

If a new thing is blocked from commercialization because it wasn’t invented here, why not reinvent it just as it is, declare ownership, and commercialize it?

If prevention is worth a pound of cure, why do people that put out forest fires get the credit while those that prevent them go unnoticed? Does that mean your career will benefit it you start small fires in private and put them out quickly for all to see?

If you always do what’s best for your career, that’s not good for your career.

When you do something that’s good for someone’s career but comes at the expense of yours, that’s good for your career.

Why not say nothing when nothing is the right thing to say?

Why not say no when no is the right thing to say?

Why not do something new even though it’s different than what was successful last time?

Why not demonstrate fearlessness and break the trail for others?

Why not be afraid and do it anyway?

Why not build on something developed by another team and give them credit?

Why not do what’s right instead of doing what’s right for your career?

Why not do something for others? As it turns out, that’s the best thing to do for yourself.

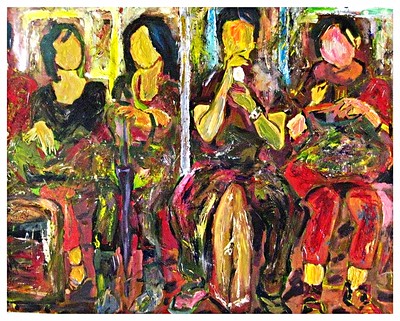

Image credit — Steve Hammond

Resource Allocation IS Strategy

In business, we have vision statements, mission statements, strategic plans, strategic initiatives, and operating plans. And every day there are there are countless decisions to make. But, in the end, it all comes down to one thing – how we allocate our resources. Whether it’s hiring people, training them, buying capital, or funding projects, all strategic decisions come back to resource allocation. Said more strongly, resource allocation is strategy.

In business, we have vision statements, mission statements, strategic plans, strategic initiatives, and operating plans. And every day there are there are countless decisions to make. But, in the end, it all comes down to one thing – how we allocate our resources. Whether it’s hiring people, training them, buying capital, or funding projects, all strategic decisions come back to resource allocation. Said more strongly, resource allocation is strategy.

Take a look back at last year. Where did you allocate your capital dollars? Which teams got it and which did not? Your capital allocation defined your priorities. The most important businesses got more capital. More to the point – the allocated capital defined their importance. Which projects were fully staffed and fully budgeted? Those that were resourced more heavily were more important to your strategy, which is why they were resourced that way. Which businesses hired people and which did not? The hiring occurred where it fulfilled the strategy. Which teams received most of the training budget? Those teams were strategically important. Prioritization in the form of resource allocation.

Repeat the process for this year’s operating plan. Where is the capital allocated? Where is the hiring allocated? Where are the projects fully staffed and budgeted? Regardless of the mission statements, this year’s strategy is defined by where the resources are allocated. Full stop.

Repeat the process for your forward-looking strategic plans. Where are the resources allocated? Which teams get more? Which get fewer? Answer these questions and you’ll have an operational definition of your company’s forward-looking strategy.

To know if the new strategy is different from the old one, look at the budgets. Do they show a change in resource allocation? Will old projects stop so new ones can start? Do the new projects serve new customers and new value propositions? Same old projects, same old customers, same old value propositions, same old strategy.

To determine if there’s a new strategy, look for changes in capital allocation. If the same teams are allocated more of the same capital, it’s likely the strategy is also the same. Will one team get more capital while the others get less? Well, it’s likely a new strategy is starting to take shape.

Look for a change in hiring. Fewer hires like last year and more of a new flavor probably indicate a change in strategy. And if people flow from one team to another, that’s the same as one team getting new hires and the other team losing them. That type of change in resource allocation is an indicator of a strategic change.

If the resource allocation differs from the strategic plan, believe the resource allocation. And if the resource allocation is the same as last year, so is the strategy. And if there is talk of changing resource allocation but no actual change, then there is no change in strategy.

Image credit – Scouse Smurf

Why is it so difficult to get ready?

The time to start getting ready is before we need to be.

The time to start getting ready is before we need to be.

We don’t get ready because the problem hasn’t yet kicked us in the head. It has only started getting ready to do so.

We don’t get ready because we don’t see the early warning signs. Like the meteorologist who doesn’t make time to look at the radar and satellite images, if we don’t look, we can’t see. And if we’re really busy, we don’t make time to look. What if it was part of our job to look at the satellite images? Who in our company should have that job?

We don’t get ready because we don’t heed the early warning signs. Seeing the warning signs is much different than justifying the reallocation of resources because someone says the tea leaves suggest an impending problem.

We will solve no problem until it’s too late to do anything else.

We don’t get ready because we forget that it takes time to get ready. We do so little getting ready, we’re unfamiliar with the work content and timeline of getting ready. We forget that getting ready is on the critical path of problem-solving.

We don’t get ready because everyone is fully booked and we have no excess capacity to allocate to getting ready. And by the time we free up the resources to get ready (if we can do that at all), we miss the window of opportunity to get ready.

We will solve a problem only after exhausting all other possibilities.

We don’t get ready because the problem is someone else’s. If we don’t have capacity to get ourselves ready for our problems why would we allocate the capacity to get ready for someone else’s?

We don’t get ready because we try to give our problem to someone else. Isn’t it easier to convince someone else to get ready than to do the getting ready ourselves?

We will solve no problem until we know we’ll get the credit.

We don’t get ready because problem avoidance won’t get us promoted, though putting out a fire that could have been avoided will.

If a problem is avoided, there is no problem. And since there’s no problem, there’s no need to avoid it.

We don’t get ready because there’s no certainty a problem will be a problem until we have it. And we can’t get ready to solve a problem once we have it. Getting ready requires judgment and trust – judgment by the person who sees the early warning signs and trust by the person who allocates the resources. It’s that simple.

Because we’ve conditioned people to be afraid to use their judgment, they don’t use it. And because we’ve conditioned people to be afraid to spend the time needed to build trust, they don’t build it.

Now that we have these two problems, how can we make it safe for people to use their judgment and spend the time needed to develop trust?

Image credit — Leonard J Matthews

Working In Domains of High Uncertainty

X: When will you be done with the project?

X: When will you be done with the project?

Me: This work has never been done before, so I don’t know.

X: But the Leadership Team just asked me when the project will be done. So, what should I say?

Me: Since nothing has changed since the last time you asked me, I still don’t know. Tell them I don’t know.

X: They won’t like that answer.

Me: They may not like the answer, but it’s the truth. And I like telling the truth.

X: Well, what are the steps you’ll take to complete the project?

Me: All I can tell you is what we’re trying to learn right now.

X: So all you can tell me is the work you’re doing right now?

Me: Yes.

X: It seems like you don’t know what you’re doing.

Me: I know what we’re doing right now.

X: But you don’t know what’s next?

Me: How could I? If this current experiment goes up in smoke, the next thing we’ll do is start a different project. And if the experiment works, we’ll do the next right thing.

X: So the project could end tomorrow?

Me: That’s right.

X: Or it could go on for a long time?

Me: That’s right too.

X: Are you always like this?

Me: Yes, I am always truthful.

X: I don’t like your answers. Maybe we should find someone else to run the project.

Me: That’s up to you. But if the new person tells you they know when the project will be done, they’re the wrong person to run the project. Any date they give you will be a guess. And I would not want to be the one to deliver a date like that to the Leadership Team.

X: We planned for the project to be done by the end of the year with incremental revenue starting in the first quarter of next year.

Me: Well, the project work is not bound by the revenue plan. It’s the other way around.

X: So, you don’t care about the profitability of the company?

Me: Of course I care. That’s why we chose this project – to provide novel customer value and sell more products.

X: So the project is intended to deliver new value to our customers?

Me: Yes, that’s how the project was justified. We started with an important problem that, if solved, would make them more profitable.

X: So you’re not just playing around in the lab.

Me: No, we’re trying to solve a customer problem as fast as we can. It only looks like we’re playing around.

X: If it works, would our company be more profitable?

Me: Absolutely.

X: Well, how can I help?

Me: Please meet with the Leadership Team and thank them for trusting us with this important project. And tell them we’re working as fast as we can.

Image credit – Florida Fish and Wildlife

X: Me: format stolen from Simon Wardley (@swardley). Thank you, Simon.

Function first, no exceptions.

Before a design can be accused of having too much material and labor costs, it must be able to meet its functional specifications. Before that is accomplished, it’s likely there’s not enough material and labor in the design and more must be added to meet the functional specifications. In that way, it likely doesn’t cost enough. If the cost is right but the design doesn’t work, you don’t have a viable offering.

Before a design can be accused of having too much material and labor costs, it must be able to meet its functional specifications. Before that is accomplished, it’s likely there’s not enough material and labor in the design and more must be added to meet the functional specifications. In that way, it likely doesn’t cost enough. If the cost is right but the design doesn’t work, you don’t have a viable offering.

Before the low-cost manufacturing process can be chosen, the design must be able to do what customers need it to do. If the design does not yet meet its functional specification, it will change and evolve until it can. And once that is accomplished, low-cost manufacturing processes can be selected that fit with the design. Sure, the design might be able to be subtly adapted to fit the manufacturing process, but only as much as it preserves the design’s ability to meet its functional requirements. If you have a low-cost manufacturing process but the design doesn’t meet the specifications, you don’t have anything to sell.

Before a product can function robustly over a wide range of operating conditions, the prototype design must be able to meet the functional requirements at nominal operating conditions. If you’re trying to improve robustness before it has worked the first time, your work is out of sequence.

Before you can predict when the project will be completed, the design must be able to meet its functional requirements. Before that, there’s no way to predict when the product will launch. If you advertise the project completion date before the design is able to meet the functional requirements, you’re guessing on the date.

When your existing customers buy an upgrade package, it’s because the upgrade functions better. If the upgrade didn’t work better, customers wouldn’t buy it.

When your existing customers replace the old product they bought from you with the new one you just launched, it’s because the new one works better. If the new one didn’t work better, customers wouldn’t buy it.

Function first, no exceptions.

Image credit — Mrs Airwolfhound

How To Finish Projects

Finishing a project is usually associated with completing all the deliverables. But in the real world there are other flavors of finishing that come when there is no reason or ability to complete all the deliverables or completing them will take too long.

Finishing a project is usually associated with completing all the deliverables. But in the real world there are other flavors of finishing that come when there is no reason or ability to complete all the deliverables or completing them will take too long.

Everyone’s favorite flavor of finishing is when all the deliverables are delivered and sales of the new product are more than anticipated. Finishing this way is good for your career. Finish this way if you can.

When most of the deliverables are met, but some of them aren’t met at the levels defined by the specification, the specification can be reduced to match the actual performance and the project can be finished. This is the right thing to do when the shortfall against the specification is minor and the product will still be well received by customers. In this case, it makes no sense to hold up the launch for a minor shortfall. There is no shame here. It’s time to finish and make money.

After working on the project for longer than planned and the deliverables aren’t met, it’s time to finish the project by stopping it. Though this type of finishing is emotionally difficult, finishing by stopping is far better than continuing to spend resources on a project that will likely never amount to anything. Think opportunity cost. If allocating resources to the project won’t translate into customer value and cash, it’s better to finish now so you can allocate the resources to a project that has a better chance of delivering value to you and your customers.

Before a project is started in earnest and the business case doesn’t make sense, or the commercial risk is too high, or the technical risk is too significant, or it’s understaffed, finish the project by not starting it. This is probably the most important type of finishing you can do. Again, think of opportunity cost. By finishing early (before starting) resources can start a new project almost immediately and resources were prevented from working on a project that wasn’t going to deliver value.

Just as we choose the right way to start projects and the right way to run them, we must choose the right way to finish them.

Image credit — majiedqasem

The Three Ts of Empowerment

If you give a person the tools, time, and training, you’ve empowered them. They know what to do, they have supporting materials, and they have the permission to spend the time they need to get it done.

If you give a person the tools, time, and training, you’ve empowered them. They know what to do, they have supporting materials, and they have the permission to spend the time they need to get it done.

If you give a person the tools and the time but not the training, they will struggle to figure out the tools but they’ll likely get there in the end. It won’t be all that efficient, but because you’ve given them the time they’ll be able to figure out the tools and get it done.

If you give a person the time but not the tools or the training, they’ll go on a random walk and make no progress. Yes, you’ve given them the time, but you’ve given them no real support or guidance. They’ll likely become tired and frustrated and you’ll have allocated their time yet made no progress.

If you give a person the tools and training but not the time, you’ve demoralized them. They have new skills and new tools and want to use them, but they’re too busy doing their day job. This is the opposite of empowerment.

If you’re not willing to give people the time to do new work, don’t bother providing new tools, and don’t bother training them. Stay the course and accept things as they are. Otherwise, you’ll disempower your best people.

But if you want to empower people, give them all three – tools, time, and training.

Image credit — Paul Balfe

The Next Evolution of Your Success

New ways to work are new because they have not been done before.

New ways to work are new because they have not been done before.

How many new ways to work have you demonstrated over the last year?

New customer value is new when it has not been shown before.

What new customer value have you demonstrated over the last year?

New ways to deliver customer value are new when you have not done it that way before.

How much customer value have you demonstrated through non-product solutions?

The success of old ways of working block new ways.

How many new ways to work have been blocked by your success?

The success of old customer value blocks new customer value.

How much new customer value has been blocked by your success with old customer value?

The success of tried and true ways to deliver customer value blocks new ways to deliver customer value.

Which new ways to deliver unique customer value have been blocked by your success?

Might you be more successful if you stop blocking yourself with your success?

How might you put your success behind you and create the next evolution of your success?

Image credit — Andy Morffew

Is the timing right?

If there is no problem, it is too soon for a solution.

If there is no problem, it is too soon for a solution.

But when there is consensus on a problem, it may be too late to solve it.

If a powerful protector of the Status Quo is to retire in a year, it may be too early to start work on the most important sacrilege.

But if the sacrilege can be done under cover, it may be time to start.

It may be too soon to put a young but talented person in a leadership position if the team is also green.

But it may be the right time to pair the younger person with a seasoned leader and move them both to the team.

When the business model is highly profitable, it may be too soon to demonstrate a more profitable business model that could obsolete the existing one.

But new business models take a long time to gestate and all business models have half-lives, so it may be time to demonstrate the new one.

If there is no budget for a project, it is too soon for the project.

But the budget may never come, so it is probably time to start the project on the smallest scale.

When the new technology becomes highly profitable, it may be too soon to demonstrate the new technology that makes it obsolete.

But like with business models, all technologies have half-lives, so it may be time to demonstrate the new technology.

The timing to do new work or make a change is never perfect. But if the timing is wrong, wait. But don’t wait too long.

If the timing isn’t right, adjust the approach to soften the conflict, e.g., pair a younger leader with a seasoned leader and move them both.

And if the timing is wrong but you think the new work cannot wait, start small.

And if the timing is horrifically wrong, start smaller.

Bucking The Best Practice

Doing what you did last works well, right up until it doesn’t.

Doing what you did last works well, right up until it doesn’t.

When you put 100% effort into doing what you did last time and get 80% of the output of last time, it’s time to do something different next time.

If it worked last time, but the environment or competition has changed, chances are it won’t work this time.

You can never step in the same river twice, and it’s the same with best practices.

Doing what you did last time is predictable until it isn’t.

The cost of trying the same thing too often is the opportunity cost of unlearned learning, which only comes from doing new things in new ways.

Our accounting systems don’t know how to capture the lost value due to unlearned learning, but your competition does.

Doing what you did last time may be efficient, but that doesn’t matter when it becomes ineffective.

Without new learning, you have a tired business model that will give you less year on year.

If you do what you did last time, you slowly learn what no longer works, but that’s all.

The best practice isn’t best when the context is different.

It’s not okay to do what you did last time all the time.

If you always do what you did last time, you don’t grow as a person.

If you do what you did last time, there are no upside surprises but there may be downside surprises.

Doing what you did last time is bad for your brain and your business.

How much of your work is repeating what you did last time? And how do you feel about that?

If you are tired of doing what you did last time, what are you going to do about it?

Might you sneak in some harmless novelty when no one is looking?

Might you conspire to try something new without raising the suspicion of the Standard Work Police?

Might you run a small experiment where the investment is small but the learning could be important?

Might you propose trying something new in a small way, highlighting the potential benefit and the safe-to-fail nature of the approach?

Might you propose small experiments run in parallel to increase the learning rate?

Might you identify an important problem that has never been solved and try to solve it?

Might you come up with a new solution that radically grows company profits?

Might you create a solution that obsoletes your company’s most profitable offering?

Might you bring your whole self to your work and see what happens?

Image credit – Marc Dalmulder

Show Them What’s Possible

When you want to figure out what’s next, show customers what’s possible. This is much different than asking them what they want. So, don’t do that. Instead, show them a physical prototype or a one-page sales tool that explains the value they would realize.

When you want to figure out what’s next, show customers what’s possible. This is much different than asking them what they want. So, don’t do that. Instead, show them a physical prototype or a one-page sales tool that explains the value they would realize.

When they see what’s possible, the world changes for them. They see their work from a new perspective. They see how the unchangeable can change. They see some impossibilities as likely. They see old constraints as new design space. They see the implications of what’s possible from their unique context. And they’re the only ones that can see it. And that’s one of the main points of showing them what’s possible – for YOU to see the implications of what’s possible from their perspective. And the second point is to hear from them what you should have shown them, how you missed the mark, and what you should show them next time.

When you show customers what’s possible, that’s not where things end. It’s where things start.

When you show customers what’s possible, it’s an invitation for them to tell you what it means to them. And it’s also an invitation for you to listen. But listening can be challenging because your context is different than theirs. And because they tell you what they think from their perspective, they cannot be wrong. They might be the wrong customer, or you might have a wrong understanding of their response, but how they see it cannot be wrong. And this can be difficult for the team to embrace.

What you do after learning from the customer is up to you. But there’s one truism – what you do next will be different because of their feedback. I am not saying you should do what they say or build what they ask for. But I think you’ll be money ahead if your path forward is informed by what you learn from the customers.

Image credit — Alexander Henning Drachmann

Mike Shipulski

Mike Shipulski