Archive for the ‘One Page Thinking’ Category

Good Teachers Are Better Than Good

Good teachers change your life. They know what you know and bring you along at a pace that’s right for you, not too slowly that you’re bored and not too quickly that your head spins. And everything they do is about you and your learning. Good teachers prioritize your learning above all else.

Good teachers change your life. They know what you know and bring you along at a pace that’s right for you, not too slowly that you’re bored and not too quickly that your head spins. And everything they do is about you and your learning. Good teachers prioritize your learning above all else.

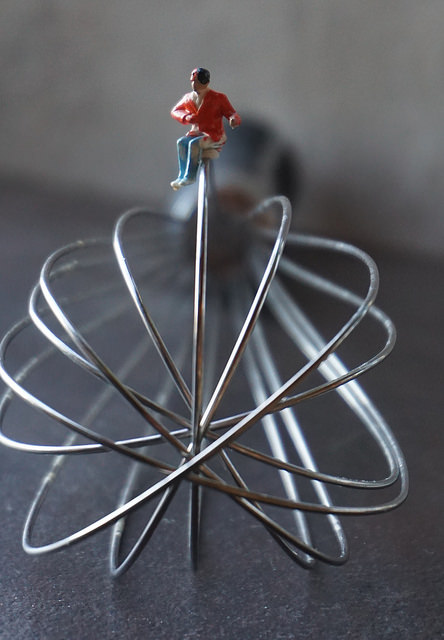

Chris Brown taught me Axiomatic Design. He helped me understand that design is more than what a product does. All meetings and discussions with Chris started with the three spaces – Functional Requirements (FRs) what it does, Design Parameters (DPs) what it looks like, and Process Variables (PVs) how to make it. This was the deepest learning of my professional life. To this day, I am colored by it. And the second thing he taught me was how to recognize functional coupling. If you change one input to the design and two outputs change, that’s functional coupling. You can manage functional coupling if you can see it. But if you can’t see it, you’re hosed. Absolutely hosed.

Vicor Fey taught me TRIZ. He helped me understand the staggering power of words to limit and shape our thinking. I will always remember when he passionately expressed in his wonderful accent, “I hate words!” And to this day, I draw pictures of problems and I avoid words. And the second thing he taught me is that a problem always exists between two things, and those things must touch each other. I make people’s lives miserable by asking – Can you draw me a picture of the problem? And, Which two system elements have the problem, and do they touch each other? And the third thing he taught me was to define problems (Yes, Victor, I know I should say conflicts.) in time. This is amazingly powerful. I ask – “Do you want to solve the problem before it happens, while it happens, or after it happens?” Defining the problem in time is magically informative.

Don Clausing taught me Robust Design. He helped me understand that you can’t pass a robustness test. He said, “If you don’t break it, you don’t know how good it is.” He was an ornery old codger, but he was right. Most tests are stopped before the product fails, and that’s wrong. He also said, “You’ve got to test the old design if you want to know if the new one is better.” To this day, I press for A/B testing, where the old design and new design are tested against the same test protocol. This is much harder than it sounds and much more powerful. He taught me to test designs at stress levels higher than the operating stresses. He said, “Test it, break it, and improve it. And when you run out of time, launch it.” And, lastly, he said, “Improve robustness at the expense of predicting it.” He gave zero value to statistics that predict robustness and 100% value to failure mode-based testing of the old design versus the new one.

The people I work with don’t know Chris, Victor, or Don. But they know the principles I learned from them. I’m a taskmaster when it comes to FRs-DPs-PVs. Designs must work well, be clearly defined by a drawing, and be easy to make. And people know there’s no place in my life for functional coupling. My coworkers know to draw a picture of the problem, and it better be done on one page. And they know the problem must be shown to exist between two things that touch. And they know they’ll get the business from me if they don’t declare that they’re solving it before, during, or after. They know that all new designs must have A/B test results, and the new one must work better than the old one. No exceptions.

I am thankful for my teachers. And I am proud to pass on what they gave me.

Image credit — Christof Timmermann

Fight Dilution!

With new product development projects, there is no partial credit. If you’re less than 100% done, there are zero sales. 90% done, zero sales. 95% done, zero sales. We all understand the concept, but our behavior often contradicts our understanding. You have too many projects, and our focus on efficiency is to blame.

With new product development projects, there is no partial credit. If you’re less than 100% done, there are zero sales. 90% done, zero sales. 95% done, zero sales. We all understand the concept, but our behavior often contradicts our understanding. You have too many projects, and our focus on efficiency is to blame.

Under the banner of efficiency, we run too many projects in parallel, and our limited resources become spread too thinly over too many projects. Project timelines grow, launch dates are pushed out, and revenue generation is delayed. And because there’s a shortfall in revenue, we start more projects to close the gap. That’s funny.

In short, we’ve morphed Start, Stop, Continue into Start, Start, Start.

Here’s a process to help you stop starting and start finishing.

Open a spreadsheet and list all your projects for the year. At the top of the column, list the projects you’ve completed. Below the completed projects, list your active projects, and below them, list your future (not yet started) projects. Highlight the completed projects and the active projects, and set the print area. Then, select “print on both sides of the page.” When you print the file, the future projects will be printed on the back of the page. This will help you focus on the completed and active projects and block you from trying to start a project before finishing one.

Now, go back to the top of the spreadsheet and select the completed projects and change the font to “strike through.” This will allow you to read the project names and remind yourself of the projects you completed. You can use this list to justify a strong performance rating at your upcoming performance review.

Skip down to the active projects and categorize them as fully staffed or partially staffed. Change the font color to red for the partially staffed projects and move them to the second page with the future projects. Print out the spreadsheet.

The completed projects will be at the top of the page in strike-through font, and the short list of fully staffed projects is listed below them in normal font. On the back of the page, the partially staffed projects are listed in red, and the future projects are listed below them. And now you’re ready to realize the power of the two-sided printout.

Step 1. Ignore the projects on the back of the page (under-staffed and yet to be started projects). They’re still on the do-do list, but they’ll wait patiently on the back of the page until resources are freed up and allocated.

Step 2. Finish the fully staffed projects on the front page.

Step 3. When you finish a project, change the font to “strike-through” and create a list of the freed-up resources.

Step 4. Flip to the back of the page, allocate the freed-up resources to one of the projects, and move the fully staffed project to the front of the page.

Step 5. Proceed to Step 2.

This is a straightforward process, but it requires great discipline.

Here’s a mantra to repeat daily – I will finish a project before I start the next one.

Image credit — iggyshoot

How I Develop Engineering Leaders

For the past two decades, I’ve actively developed engineering leaders. A good friend asked me how I do it, so I took some time to write it down. Here is the curriculum in the form of How Tos:

For the past two decades, I’ve actively developed engineering leaders. A good friend asked me how I do it, so I took some time to write it down. Here is the curriculum in the form of How Tos:

How to build trust. This is the first thing. Always. Done right, the trust-based informal networks are stronger than the formal organization chart. Done right, the informal networks can protect the company from bad decisions. Done right, the right information flows among the right engineers at the right time so the right work happens in the right way.

How to decide what to do next. This is a broad one. We start with a series of questions: What are we doing now? What’s the problem? How do you know? What should we do more of? What should we do less of? What resources are available? When must we be done?

How to map the current state. We don’t define the idealized future state or the North Star, we start with what’s happening now. We make one-page maps of the territory. We use drawings, flow charts, boxes/arrows, and the fewest words. And we take no action before there’s agreement on how things are. The value of GPS isn’t to define your destination, it’s to establish your location. That’s why we map the current state.

How to build momentum. It’s easy to jump onto a moving steam train, but a stationary one is difficult to get moving. We define the active projects and ask – How might we hitch our wagon to a fast-moving train?

How to start something new. We start small and make a thought-provoking demo. The prototype forces us to think through all the elements, makes things real, and helps others understand the concept. If that doesn’t work, we start smaller.

How to define problems so we can solve them easily. We define problems with blocks and arrows, and limit ourselves to one page. The problem is defined as a region of contact between two things, and we identify it with the color red. That helps us know where the problem is and when it occurs. If there are two problems on a page, we break it up into two pages with one problem. Then we decide to solve the problem before, during, or after it occurs.

How to design products that work better and cost less. We create Pareto charts of the cost of the existing product (cost by subassembly and cost by part) and set a cost reduction goal. We create Pareto charts of the part count of the existing product (part count by subassembly and part count by individual part number) and define a goal for part count reduction. We define test protocols that capture the functionality customers care about. We test the existing product and set performance improvement goals for the new one. We test the new product using the same protocols and show the data in a simple A-B format. We present all this data at formal design reviews.

How to define technology projects. We define how the customer does their work. We then define the evolutionary history of our products and services, and project that history forward. For lines of goodness with trajectories that predict improvement, we run projects to improve them. For lines of goodness with stalled trajectories, we run projects to establish new technologies and jump to the next S-curve. We assess our offerings for completeness and create technologies to fill the gap.

How to file the right patents. We ask these questions: How quickly will the customer notice the new functionality or benefit? Once recognized, will they care? Will the patent protect high-volume / high-margin consumables? There are more questions, but these are the ones we start with. And the patent team is an integral part of the technology reviews and product development process.

How to do the learning. We start with the leader’s existing goals and deliverables and identify the necessary How Tos to get their work done. There are no special projects or extra work.

If you’re interested in learning more about the curriculum or how to enroll, send me an email mike@shipulski.com.

Image credit — Paul VanDerWerf

Improve Focus To Improve Effectiveness

Business is about the effective allocation of resources. Companies win when they do that better than their competitors. Full stop. If you believe that, the question is how to allocate resources effectively. To me, everything starts with a map of the territory – a single-page map of today’s projects, the people you have, and the tools/infrastructure you have. In short, before you can reallocate resources, map how you allocate them now.

Business is about the effective allocation of resources. Companies win when they do that better than their competitors. Full stop. If you believe that, the question is how to allocate resources effectively. To me, everything starts with a map of the territory – a single-page map of today’s projects, the people you have, and the tools/infrastructure you have. In short, before you can reallocate resources, map how you allocate them now.

Let the mapping begin.

The first step is to create a one-page summary (a map) of the resources on hand and the projects they work on (how they are allocated). A simple spreadsheet is the way to go. At the top, running left to right, list the names of all the people. Give each person their column. On the left, running top to bottom, list the active projects, one project per row. For each project, move left to right and ask if the person works on the project. Put an X in their column if they contribute to the project in any way. If they work on the project 2% of their time or more, X marks the spot. You will be reluctant to do this, but the process is more meaningful if you do.

No fancy formats, no extra text, no headings, no footers, just columns of people against rows of projects. And it MUST fit one page. MUST. Reduce the font size and the margins to fit it on one page. And if that doesn’t work, set the print area and choose the setting that scales the print area to fit on one page. Put it on 11 by 17 paper if you must, but you must put it on one page. You’ll have to squint to read the font when you do it right.

When you look at the one-page printout, the first thing you will notice is that you have too many rows because you have too many projects. (And, yes, you should list the quiet projects no one knows about.) The second thing you will notice is that everyone has too many Xs because they work on too many projects. The third thing is some people have far more Xs than everyone else’s too many Xs. All the project managers want them on the projects because they are good at getting projects done.

Let the culling begin.

It’s time to stop. The best way to stop is to set a maximum time threshold to deliver the first dollar of revenue. Any project that cannot deliver revenue sooner than the threshold should stop. The threshold method is crude, fast, and effective. It’s a great way to do the first pass culling. For those projects that are difficult to stop due to political factors, don’t stop them but, rather, strongly pause them. Then, use the reallocation process (described later) to move resources to better projects and let the politically charged projects die a slow death. Good process beats bad projects.

Strike the cancelled projects from the record, eliminate their rows, and reprint the one-page map. If you have the right number of projects and they’re fully staffed (this is unlikely), execute the projects that made the cut. If you have too few projects, the next step is to come up with a set of new projects that deliver revenue sooner than the culled projects. If you still have too many projects (too many people with too many Xs), it’s time to thin the herd again. Sort the projects by the revenue they will generate over the threshold period plus three years. The best projects will bubble to the top, and the bad ones will sink to the bottom.

Let the reallocating begin.

Now, delete all the Xs from the spreadsheet so none of the projects are staffed and no one has a project. Start with the top row (your best project), move left to right, and place an X in the columns until the project is fully staffed. Allocate the resources to your best project and get after it right now. Because your best project was understaffed, incremental will flow to the project. This will increase the probability you will hit the launch date or even pull it in.

Next, move down one row to your second-best project and repeat the process. Add Xs left to right until the project is fully staffed. But this time there’s a constraint – each column can contain only one X. Because the people are now fully allocated to and actively working on your best project, they cannot work on the second-best project. With all the Xs in place and your second-best project fully staffed, work the project hard with the reallocated resources. Pull in the timeline if you can.

Repeat the process project by project until you can no longer fully staff a project. And here’s where the game gets interesting. Don’t work a project you cannot staff fully. There. I said it. With new product development projects, there is no partial credit. They’re either 100% done or 0% done. A project that’s 80% done delivers 0% of the revenue. But it’s worse than that. Making “progress” on a project that won’t launch because it’s understaffed consumes functional support resources and will slow down your most important projects. Don’t do that. Don’t run the project. Just don’t. You’re better off paying the people to stay home so they don’t consume functional resources needed by the more important projects.

Instead of paying the people to stay home, try to add them to the active projects so you can launch those sooner. In theory, those projects are fully staffed, but old behaviors die hard, and you probably didn’t fully staff the most important projects. For the people who still don’t have a project (they cannot speed up the projects), train them on the skills/tools they’ll need for the next round of projects. This will help you do the next projects better and faster. Or, they could start on more forward-looking projects that don’t consume resources needed by the more urgent projects.

The process to allocate people to the most important projects is the same for resources like infrastructure for reliability testing or product validation. With the same fully-staff-the-project approach, allocate the infrastructure resources to the most important projects. Once there is no more infrastructure capacity, don’t run an under-resourced project. If you run the lesser project, it will consume those precious infrastructure resources and slow down your most important projects.

You likely won’t be able to staff projects such that each person works on a single project. The concept is more directional than literal. Working on three projects is better than working on four, and two is better than three.

I did not describe how to estimate the project revenues, how to create new projects that deliver more revenue sooner, or how to create the right mix of projects – short, medium, and long. But in a first-things-first way, I suggest you start with a singular focus – reallocate resources to your best projects (and, likely, fewer of them), so those projects effectively deliver revenue your company needs.

I think more focus will bring you more effectiveness.

Image credit — Charlie Wales

Can you put it on one page?

Anyone can create a presentation with thirty slides, but it takes a rare bird to present for thirty minutes with a single slide.

Anyone can create a presentation with thirty slides, but it takes a rare bird to present for thirty minutes with a single slide.

With thirty slides you can fully describe the system. With one slide you must know what’s important and leave the rest. With thirty slides you can hide your lack of knowledge. With one slide it’s clear to all that you know your stuff, or you don’t.

With one slide you’ve got to know all facets of the topic so you can explain the interactions and subtleties on demand. With thirty slides you can jump to the slide with the answer to the question. That’s one of the main reasons to have thirty slides.

It’s faster to create a presentation with thirty slides than a one-slide presentation. The thirty slides might take ten hours to create, but it takes decades of experience and study to create a one-slide presentation.

If you can create a hand sketch of the concept and explain it for thirty minutes, you will deliver a dissertation. With a one-slide-per-minute presentation, that half hour will be no more than a regurgitation.

Thirty slides are a crutch. One slide is a masterclass.

Thirty slides – diluted. One slide – distilled.

Thirty slides – tortuous. One slide – tight.

Thirty slides – clogged. One slide – clean.

Thirty slides – convoluted. One slide – clear.

Thirty slides – sheet music. One slide – a symphony.

With fewer slides, you get more power points.

With fewer slides, you get more discussion.

With fewer slides, you show your stuff more.

With fewer slides, you get to tell more stories.

With fewer slides, you deliver more understanding.

If you delete half your slides your presentation will be more effective.

If you delete half your slides you’ll stand out.

If you delete half your slides people will remember.

If you delete half your slides the worst outcome is your presentation is shorter and tighter.

Why not reduce your slides by half and see what happens?

And if that goes well, why not try it with a single slide?

I have never met a presentation with too few slides.

Image credit — NASA Goddard

How To Make Progress

Improvement is progress. Improvement is always measured against a baseline, so the first thing to do is to establish the baseline, the thing you make today, the thing you want to improve. Create an environment to test what you make today, create the test fixtures, define the inputs, create the measurement systems, and write a formal test protocol. Now you have what it takes to quantify an improvement objectively. Test the existing product to define the baseline. No, you haven’t improved anything, but you’ve done the right first thing.

Improvement is progress. Improvement is always measured against a baseline, so the first thing to do is to establish the baseline, the thing you make today, the thing you want to improve. Create an environment to test what you make today, create the test fixtures, define the inputs, create the measurement systems, and write a formal test protocol. Now you have what it takes to quantify an improvement objectively. Test the existing product to define the baseline. No, you haven’t improved anything, but you’ve done the right first thing.

Improving the right thing to make progress. If the problem invalidates the business model, stop what you’re doing and solve it right away because you don’t have a business if you don’t solve it. Any other activity isn’t progress, it’s dilution. Say no to everything else and solve it. This is how rapid progress is made. If the customer won’t buy the product if the problem isn’t solved, solve it. Don’t argue about priorities, don’t use shared resources, don’t try to be efficient. Be effective. Do one thing. Solve it. This type of discipline reduces time to market. No surprises here.

Avoiding improvement of the wrong thing to make progress. For lesser problems, declare them nuisances and permit yourself to solve them later. Nuisances don’t have to be solved immediately (if at all) so you can double down on the most important problems (speed, speed, speed). Demoting problems to nuisances is probably the most effective way to accelerate progress. Deciding what you won’t do frees up resources and emotional bandwidth to make rapid progress on things that matter.

Work the critical path to make progress. Know what work is on the critical path and what is not. For work on the critical path, add resources. Pull resources from non-critical path work and add them to the critical path until adding more slows things down.

Eliminate waiting to make progress. There can be no progress while you wait. Wait for a tool, no progress. Wait for a part from a supplier, no progress. Wait for raw material, no progress. Wait for a shared resource, no progress. Buy the right tools and keep them at the workstations to make progress. Pay the supplier for priority service levels to make progress. Buy inventory of raw materials to make progress. Ensure shared resources are wildly underutilized so they’re available to make progress whenever you need to. Think fire stations, fire trucks, and firefighters.

Help the team make progress. As a leader, jump right in and help the team know what progress looks like. Praise the crudeness of their prototypes to help them make them cruder (and faster) next time. Give them permission to make assumptions and use their judgment because that’s where speed comes from. And when you see “activity” call it by name so they can recognize it for themselves, and teach them how to turn their effort into progress.

Be relentless and respectful to make progress. Apply constant pressure, but make it sustainable and fun.

Image credit — Clint Mason

Learn in small batches, rinse and repeat.

When the work is new, it can’t be defined and managed like work that has been done before.

When the work is new, it can’t be defined and managed like work that has been done before.

Sometimes there’s a tendency to spend months to define the market, the detailed specification and the project timeline and release the package as a tidal wave that floods the organization with new work. Instead, start with a high-level description of the market, a rough specification and the major project milestones, all of which will morph, grow and inform each other as the team learns. Instead of a big batch, think bite-sized installments that build on each other. Think straw-man that gets its flesh as the various organizations define their learning objectives and learn them.

Instead of target customer segments and idealized personas, define how the customers will interact with the new product or service. Use the storyboard format to capture sequence of events (what they do), the questions they ask themselves and how they know they’ve done it right. Make a storyboard for the top three to five most important activities the customers must do. There’s good learning just trying to decide on the top three to five activities, never mind the deep learning that comes when you try to capture real activities of real customers. [Hint – the best people to capture real customer activities are real customers.]

Instead of a detailed list of inputs and outputs, fill in the details of the storyboards. Create close-ups of the user interfaces and label the dials, buttons and screens. When done well, the required inputs and outputs bubble to the surface. And define the customer’s navigation path, as it defines the sequence of things and where the various inputs come to be and the various outputs need to be. What’s nice is learning by iteration can be done quickly since its done in the domain of whiteboards and markers.

Instead of defining everything, just define what’s new and declare everything else is the same as last time.

The specification for the first prototypes is to bring the storyboards to life and to show the prototypes to real customers. Refine and revise based on the learning, and rinse and repeat, as needed.

As the design migrates toward customer value and confidence builds, it’s then time to layer on the details and do a deep dive into the details – specs, test protocols, manufacturing, sales and distribution.

At early stages of innovation work, progress isn’t defined by activity, it’s defined by learning. And it can look like nothing meaningful is happening as there is a lot of thinking and quiet time mixed in with infrequent bursts active activity. But that’s what it takes to answer the big questions of the front end.

When in doubt, answer the big questions at the expense of the details. And to stay on track, revisit and refine the learning objectives. And to improve confidence, show it to real customers.

And rinse and repeat, as needed.

Image credit – Jason Samfield

How To Reduce Innovation Risk

The trouble with innovation is it’s risky. Sure, the upside is nice (increased sales), but the downside (it doesn’t work) is distasteful. Everyone is looking for the magic pill to change the risk-reward ratio of innovation, but there is no pill. Though there are some things you can do to tip the scale in your favor.

The trouble with innovation is it’s risky. Sure, the upside is nice (increased sales), but the downside (it doesn’t work) is distasteful. Everyone is looking for the magic pill to change the risk-reward ratio of innovation, but there is no pill. Though there are some things you can do to tip the scale in your favor.

All problems are business problems. Problem solving is the key to innovation, and all problems are business problems. And as companies embrace the triple bottom line philosophy, where they strive to make progress in three areas – environmental, social and financial, there’s a clear framework to define business problems.

Start with a business objective. It’s best to define a business problem in terms of a shortcoming in business results. And the holy grail of business objectives is the growth objective. No one wants to be the obstacle, but, more importantly, everyone is happy to align their career with closing the gap in the growth objective. In that way, if solving a problem is directly linked to achieving the growth objective, it will get solved.

Sell more. The best way to achieve the growth objective is to sell more. Bottom line savings won’t get you there. You need the sizzle of the top line. When solving a problem is linked to selling more, it will get solved.

Customers are the only people that buy things. If you want to sell more, you’ve got to sell it to customers. And customers buy novel usefulness. When solving a problem creates novel usefulness that customers like, the problem will get solved. However, before trying to solve the problem, verify customers will buy what you’re selling.

No-To-Yes. Small increases in efficiency and productivity don’t cause customers to radically change their buying habits. For that your new product or service must do something new. In a No-To-Yes way, the old one couldn’t but the new one can. If solving the problem turns no to yes, it will get solved.

Would they buy it? Before solving, make sure customers will buy the useful novelty. (To know, clearly define the novelty in a hand sketch and ask them what they think.) If they say yes, see the next question.

Would it meet our growth objectives? Before solving, do the math. Does the solution result in incremental sales larger than the growth objective? If yes, see the next question.

Would we commercialize it? Before solving, map out the commercialization work. If there are no resources to commercialize, stop. If the resources to commercialize would be freed up, solve it.

Defining is solving. Up until now, solving has been premature. And it’s still not time. Create a functional model of the existing product or service using blocks (nouns) and arrows (verbs). Then, to create the problem(s), add/modify/delete functions to enable the novel usefulness customers will buy. There will be at least one problem – the system cannot perform the new function. Now it’s time to take a deep dive into the physics and bring the new function to life. There will likely be other problems. Existing functions may be blocked by the changes needed for the new function. Harmful actions may develop or some functions will be satisfied in an insufficient way. The key is to understand the physics in the most complete way. And solve one problem at a time.

Adaptation before creation. Most problems have been solved in another industry. Instead of reinventing the wheel, use TRIZ to find the solutions in other industries and adapt them to your product or service. This is a powerful lever to reduce innovation risk.

There’s nothing worse than solving the wrong problem. And you know it’s the wrong problem if the solution doesn’t: solve a business problem, achieve the growth objective, create more sales, provide No-To-Yes functionality customers will buy, and you won’t allocate the resources to commercialize.

And if the problem successfully runs the gauntlet and is worth solving, spend time to define it rigorously. To understand the bedrock physics, create a functional of the system, add the new functionality and see what breaks. Then use TRIZ to create a generic solution, search for the solution across other industries and adapt it.

The key to innovation is problem solving. But to reduce the risk, before solving, spend time and energy to make sure it’s the right problem to solve.

It’s far faster to solve the right problem slowly than to solve the wrong one quickly.

Image credit – Kate Ter Haar

Hire people that run toward even the toughest problems.

If you don’t have a problem, there’s no problem. There are no resources without a problem and certainly no focus or momentum. If you don’t know your problem, stop. Take time to define your problem using a single page. Make a sketch or make a block diagram but make it clear. Make it so the problem description stands on its own. After you’ve defined your problem and someone calls it an “opportunity”, walk away because they can’t help you. Taking advantage of opportunities is optional, but solving problems is mission critical. No one worth their salt works on opportunities. Rock stars solve problems.

If you don’t have a problem, there’s no problem. There are no resources without a problem and certainly no focus or momentum. If you don’t know your problem, stop. Take time to define your problem using a single page. Make a sketch or make a block diagram but make it clear. Make it so the problem description stands on its own. After you’ve defined your problem and someone calls it an “opportunity”, walk away because they can’t help you. Taking advantage of opportunities is optional, but solving problems is mission critical. No one worth their salt works on opportunities. Rock stars solve problems.

After you’ve gnawed on a problem for a month and it hasn’t given in, what do you do? When you’ve thrown everything at a problem and it still stands tall, what do you do? When you’ve tried all your tricks and the intractable problem is still blocking an already overdue product launch, what do you do? What you do is find someone who is unafraid trade an intractable problem for a solvable one, someone who will courageously give ground with the hope of opening up new design space, someone who will unabashedly take an anti-conventional (and hopefully controversial) approach. What you do is find a rock star.

Intractable problems are not usually intractable; rather, intractable problems are either poorly-defined problems or are the wrong problem altogether. Either way, it takes someone with courage, usually an outsider, to redefine the problem or see it differently. But because of pride, an outsider can be brought in only after the team has exhausted all other possibilities. Unless there’s a problem with the problem solving team (they can’t solve the problem), there’s no problem. And without a problem, the team won’t accept help from an outsider.

At the rodeo when the cowboy is bucked off the raging bull, the cowboy runs away from the bull but the rodeo clown runs toward the bull to distract it. Like the rodeo clown, the problem solving rock star runs toward raging problems at full tilt. The rock star puts it all on the line as she grabs the problem by the scruff of the neck, wrestles it to the ground and hog ties it. There’s no shyness, just well-practiced technique wrapped in implicit knowledge. With courage and a cloud of dust, it’s no-holds-barred problem solving until the problem gives it up. Nothing is sacred, no assumptions go unchallenged, and no details are too small to ignore. Like rodeo clowns, rock stars know their work looks funny from the outside, but they don’t care. All they care about is solving the problem at hand. Right here, right now.

Before your next intractable problem, take a minute to scan your organization for the special people who have the courage to run toward even the most difficult problems. Don’t be fooled by titles, positional power or how they dress. Look deeply because like rodeo clowns, your magical problem solvers may not look the part on the outside.

Image credit – Ed Schipul

There Are No Best Practices

That’s a best practice. Look, there’s another one. We need a best practice. What’s the best practice? Let’s standardize on the best practice. Arrrgh. Enough, already, with best practices.

That’s a best practice. Look, there’s another one. We need a best practice. What’s the best practice? Let’s standardize on the best practice. Arrrgh. Enough, already, with best practices.

There are no best practices, only actions that have worked for others in other situations. Yet we feverishly seek them out, apply them out of context, and expect they’ll solve a problem unrelated to their heritage.

To me, the right practices are today’s practices. They’re the base camp from which to start a journey toward new ones. To create the next evolution of today’s practices, for new practices to emerge, a destination must be defined. This destination is dictated by problems with what we do today. Ultimately, at the highest level, problems with our practices are spawned by gaps, shortfalls, or problems in meeting company objectives. Define the shortfall – 15% increase in profits – and emergent practices naturally diffuse to the surface.

There are two choices: choose someone else’s best practices and twist, prune, and bend them to fit, or define the incremental functionality you’d like to create and lay out the activities (practices) to make it happen. Either way, the key is starting with the problem.

The important part – the right practices, the new activities, the novel work, whatever you call it, emerges from the need.

It’s a problem hierarchy, a problem flow-down. The company starts by declaring a problem – profits must increase by 15% – and the drill-down occurs until a set of new action (new behaviors, new processes, new activities) is defined that solves the low level problems. And when the low level problems are solved, the benefits avalanche to satisfy the declared problem – profits increased by 15%.

It’s all about clarity — clearly define the starting point, clearly define the destination, and express the gaps in a single page, picture-based problem statements. With this type of problem definition, you can put your hand over your mouth, with the other hand point to the picture, and everyone understands it the same way. No words, just understanding.

And once everyone understands things clearly, the right next steps (new practices) emerge.

Pushing on Engineering

With manufacturing change is easy – lean this, six sigma that, more with less year-on-year. With engineering, not so much. Why?

With manufacturing change is easy – lean this, six sigma that, more with less year-on-year. With engineering, not so much. Why?

Manufacturing is about cost, waste, efficiency, and yield (how to make it), and engineering is about function (what it does) – fundamental differences but not the why. The consequence of failure is the why. If manufacturing doesn’t deliver, the product is made like last year (with a bit more waste and cost than planned), but the product still sells. With engineering, not so much. If engineering mistakenly designs the Fris out of the Frisbee or the Hula out of the Hoop, no sales. That’s the why.

No function, no sales, no company, this is fear. This is why it feels dangerous to push on engineering; push on engineering and the wheels may fall off. This why the organization treads lightly; this is why the CEO does not push.

As technical leaders we are the ones who push directly on engineers. We stretch them to create novel technology that creates customer value and drive sales. (If, of course, customers value the technology.) We spend our days in the domain of stress, strain, printed circuit boards, programming languages, thermal models, and egos. As technologists, it’s daunting to push effectively on engineering; as non-technologists even more. How can a CEO do it without the subject matter expertise? The answer is one-page thinking.

One-page thinking forces engineers to describe our work in plain English, simple English, simple language, pictures, images. This cuts clutter and cleans our thinking so non-technologists can understand what’s happening, what’s going on, what we’re thinking, and shape us in the direction of customer, of market, of sales. The result is a hybrid of strong technology, strong technical thinking, and strong product, all with a customer focus, a market focus. A winning combination.

There are several rules to one-page thinking, but start with this one:

Use one page.

As CEO, ask your technical leaders (even the VP or SVP kind) to define each of their product development (or technology) projects on one page, but don’t tell them how. (The struggle creates learning.) When they come back with fifteen PowerPoint slides (a nice reduction from fifty), read just the first one, and send them away. When they come back with five, just read the first. They’ll get the idea. But be patient. To use just one page makes things remarkably clear, but it’s remarkably difficult.

Once the new product (or technology) is defined on one page, it’s time to reduce the fear of pushing on engineering – one-page thinking at the problem level. First, ask the technical leaders for a one-page description of each problem that must be overcome (one page per problem and address only the fundamental problems). Next, for each problem ask for baseline data (test data) on the product you make today. (For each problem they’ll likely have to create a robustness surrogate, a test rig to evaluate product performance.) The problem is solved (and the product will function well) when the new one out-performs the old one. The fear is gone.

When your engineers don’t understand, they can’t explain things on one page. But when they can, you understand.

Mike Shipulski

Mike Shipulski