Archive for February, 2012

Heroes of the Company

If I was a company, the first thing I’d do is invest in my engineering teams. But not for the reasons we normally associate with engineering. Not for more function and features, not for product robustness, not technology, and not patents. I would invest in engineering for increased profits.

If I was a company, the first thing I’d do is invest in my engineering teams. But not for the reasons we normally associate with engineering. Not for more function and features, not for product robustness, not technology, and not patents. I would invest in engineering for increased profits.

When it comes to their engineering divisions, other companies think minimization – fewest heads, lowest wages, least expensive tools. Not me. I’m all about maximization – smartest, best trained, and the best tools. That’s how I like to maximize profits. To me, investing in my engineering teams gives me the highest return on my investment.

Engineers create the products I sell to my customers. I’ve found when my best engineers sit down and think for a while they come up with magical ideas that translate into super-performing products, products with features that differentiate me from my cousin companies, and products that flat-out don’t break. My sales teams love to sell them (Sure, I pay a lot in bonuses, but it’s worth it.), my marketing teams love to market them, and my factory folks build them with a smile.

Over my life I’ve developed some simple truisms that I live by: When I sell more products, I make more profits; when my products allow a differentiated marketing message, I sell more and make more profits; and when my product jumps together, my quality is better, and, you guessed it, I make more profits. All these are good reasons to invest in engineering, but it’s not my reason. All this increased sales stuff is good, but it’s not great. It’s not my real reason to invest in engineering. It’s not my secret.

When I was younger I vowed to take my secret to the grave, but now that I’ve matured (and filled up several banks with money), I think it’s okay to share it. So, here goes.

My real reason to invest in engineering is material cost reduction. Yes, material cost reduction. My materials budget is one of my largest line items and I help my engineers reduce it with reckless abandon (and the right tools, time, training, and teacher.) I’ve asked my lean folks to reduce material cost, but they’ve not been able to dent it. Sure, they’ve done a super job with inventory reduction (I get a one-time carrying cost reduction.), but no material cost reduction from my lean projects. I’ve also asked my six sigma organization to reduce material costs, but they, too, have not made a dent. They’ve improved my product quality, but that doesn’t translate into piles of money like material cost reduction.

Now, I know what you’re thinking: Why, Mrs. Company, are you wasting engineering’s time with cost? Cost is manufacturing’s responsibility – they should reduce it, not engineering. Plain and simple – that’s not what I believe, and neither do my engineers. They know they create cost to enable function, good material cost – worth every penny. But they also know all other cost is bad. And since they know they design in cost, they know they’re the ones that must design it out. And they’re good at it. With the right tools, time, and training, they typically reduce material costs by 50%. Do the math –material cost for your highest volume product times 50% – year-on-year. Piles of money.

I’ve learned over the years increasing sales is difficult and takes a lot of work. I’ve also learned I can make lots of money reducing material costs without increasing sales. In fact, even during the recent downturn, through my material cost reductions I made more money than ever. I have my design engineers to thank for that.

Company-to-company, I know things have been tough for us over the last years, and money is still tight. But if you have a little extra stashed away, I urge you to invest in your engineering organization. It makes for great profits.

Upcoming Workshop on Systematic DFMA Deployment – June 2012

Systematic DFMA Deployment – How To Implement for Increased Profits

I am running a half-day workshop on June 13 in Providence, RI. The workshop is part of the 2012 International Forum on Design for Manufacturing and Assembly. I will focus on how to increase profits and incorporate DFMA into your product development process.

I am running a half-day workshop on June 13 in Providence, RI. The workshop is part of the 2012 International Forum on Design for Manufacturing and Assembly. I will focus on how to increase profits and incorporate DFMA into your product development process.

The conference (June 11-13) is the yearly gathering of the world’s DFMA experts. It is THE place to learn about DFMA and see examples and results from leading companies.

(I am also presenting a paper at the conference – Conference Program).

I urge the product development community to attend.

I hope to finally meet you in person.

Can’t Say NO

- Yes is easy, no is hard.

- Sometimes slower is faster.

- Yes, and here’s what it will take:

- The best choose what they’ll not do.

- Judge people on what they say no to.

- Work and resources are a matched pair.

- Define the work you’ll do and do just that.

- Adding scope is easy, but taking it out is hard.

- Map yes to a project plan based on work content.

- Challenge yourself to challenge your thinking on no.

- Saying yes to something means saying no to something else.

- The best have chosen wrong before, that’s why they’re the best.

- It’s better to take one bite and swallow than take three and choke.

Be Your Stiffest Competitor

Your business is going away. Not if, when. Someone’s going to make it go away and it might as well be you. Why not take control and make it go away on your own terms? Why not make it go away and replace it with something bigger and better?

Your business is going away. Not if, when. Someone’s going to make it go away and it might as well be you. Why not take control and make it go away on your own terms? Why not make it go away and replace it with something bigger and better?

Success is good, but fleeting. Like a roller coaster with up-and-up clicking and clacking, there’s a drop coming. But with a roller coaster we expect it – there’s always a drop. (That’s what makes it a roller coaster.) We get ready for it, we brace ourselves. Half-scared and half-excited, electricity fills us, self-made fight-or-flight energy that keeps us safe. I think success should be the same – we should expect the drop.

More strongly we should manage the drop, make it happen on our terms. But that’s going to be difficult. Success makes it easy to unknowingly slip into protecting-what-we-have mode. If we’re to manage the drop, we must learn to relish it like the roller coaster. As we’re ascending – on the way up – we must learn to create a healthy discomfort around success, like the sweaty-palm feeling of the roller coaster’s impending wild ride.

A sky-is-falling approach won’t help us embrace the drop. With success all around, even the best roller coaster argument will be overpowered. The argument must be based on positivity. Acknowledge success, celebrate it, and then challenge your organization to improve on it. Help your organization see today’s success as the foundation for the future’s success – like standing on the shoulders of giants. But in this case, the next level of success will be achieved by dismantling what you’ve built.

No one knows what the future will be, other than there will be increased competition. Hopefully, in the future, your stiffest competitor will be you.

Seeing Things As They Are

It’s tough out there. Last year we threw the kitchen sink at our processes and improved them, and now last year’s improvements are this year’s baseline. And, more significantly, competition has increased exponentially – there are more eager countries at the manufacturing party. More countries have learned that manufacturing jobs are the bedrock of sustainable economy. They’ve designed country-level strategies and multi-decade investment plans (education, infrastructure, and energy technologies) to go after manufacturing jobs as if their survival depended on them. And they’re not just making, they’re designing and making. Country-level strategies and investments, designing and making, and citizens with immense determination to raise their standard of living – a deadly cocktail. (Have you seen Hyundai’s cars lately?)

It’s tough out there. Last year we threw the kitchen sink at our processes and improved them, and now last year’s improvements are this year’s baseline. And, more significantly, competition has increased exponentially – there are more eager countries at the manufacturing party. More countries have learned that manufacturing jobs are the bedrock of sustainable economy. They’ve designed country-level strategies and multi-decade investment plans (education, infrastructure, and energy technologies) to go after manufacturing jobs as if their survival depended on them. And they’re not just making, they’re designing and making. Country-level strategies and investments, designing and making, and citizens with immense determination to raise their standard of living – a deadly cocktail. (Have you seen Hyundai’s cars lately?)

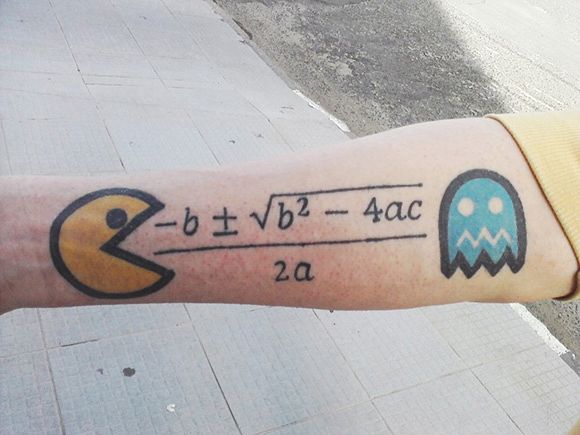

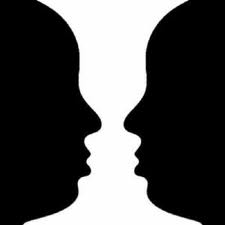

With the wicked couple of competition and profitability goals, we’re under a lot of pressure. And with the pressure comes the danger of seeing things how we want them instead of how they are, like a self-created optical illusion. Here are some likely optical illusion A-B pairs (A – how we want things; B – how they are):

A. Give people more work and more gets done. B. Human output has a physical limit, and once reached less gets done – and spouses get angry. A. Do more projects in parallel to generate more profit. B. Business processes have physical limits, and once reached projects slow and everyone works harder for the same output. A. Add resources to the core project team and more projects get done. B. Add resources to core projects teams and utilization skyrockets for shared resources – waiting time increases for all. A. Use lean in product development (just like in manufacturing) to launch new products better and faster. B. Lean done in product development is absolutely different than in manufacturing, and design engineers don’t take kindly to manufacturing folks telling them how to do their work. A. Through negotiation and price reduction, suppliers can deliver cost reductions year-on-year. B. The profit equation has a physical limit (no profit), and once reached there is no supplier. A. Use lean to reduce product cost by 5%. B. Use DFMA to reduce product cost by 50%.Competition is severe and the pressure is real. And so is the danger to see things as we want them to be. But there’s a simple way to see things as they are: ask the people that do the work. Go to the work and ask the experts. They do the work day-in-day-out, and they know what really happens. They know the details, the pinch points, and the critical interactions.

To see things as they are, check your ego at the door, and go ask the experts – the people that do the work.

Lean and Supply Chain Sensitivity

At every turn, lean has increased profits in the factory. Its best trick is to look at the work through a time lens, see wasted time, and get rid of it.

At every turn, lean has increased profits in the factory. Its best trick is to look at the work through a time lens, see wasted time, and get rid of it.

Work is blocked by problems. You watch the work to spot blockages in the form of piles, otherwise known as inventory. When you find a pile, you know the problem is one operation downstream.

As lean works its magic, inventory is reduced, which decreases carrying costs. More importantly, however, it also reduces the time to see a problem. Whether the problem is related to quality, delivery or resources, everything stops immediately. It’s clear what to fix, and there’s incentive to fix it quickly because with lean, the factory is more sensitive to problems.

What works in the factory will also work in the supply chain, and that’s where lean is going.

When It’s Time For a New Cowpath

Doing new things doesn’t take a long time. What takes a long time is seeing things as they are. Getting ready takes time, not doing new. Awareness of assumptions, your assumptions, others’ assumptions, the company’s – that’s critical path.

Doing new things doesn’t take a long time. What takes a long time is seeing things as they are. Getting ready takes time, not doing new. Awareness of assumptions, your assumptions, others’ assumptions, the company’s – that’s critical path.

An existing design, product, service, or process looks as it does because of assumptions made during long ago for reasons no longer relevant (if they ever were). Design elements blindly carried forward, design approaches deemed gospel, scripted service policies that no longer make sense, awkward process steps proceduralized and rev controlled – all artifacts of old, unchallenged assumptions. And as they grow roots, assumptions blossom into constraints. Fertile design space blocked, new technologies squelched, new approaches laughed out of town – all in the name of constraints founded on wilted assumptions. And the most successful assumptions have the deepest roots and create the deepest grooves of behavior.

Cows do the same thing every day. They wake up at the same time (regardless of daylight savings), get milked at the same time, and walk the same path. They walk in such a repeatable way, they make cowpaths – neat grooves walked into the landscape – curiously curved paths with pre-made decisions. No cow worth her salt walks outside the cowpath. No need. Cows like to save their energy for making milk at the expense of making decisions. If it was the right path yesterday, it’s right today.

But how to tell when old assumptions limit more than they guide? How to tell when it’s time to step out of the groove? How to tell a perfectly good cowpath from one that leads to a dry watering hole? When is it time to step back and create new history? Long ago the first cow had to make a choice, and she did. She could have gone any which way, and she did. She made the path we follow today.

With blind acceptance of assumptions, we wither into bankruptcy, and with constant second-guessing we stall progress. We must strike a balance. We must hold healthy respect for what has worked and healthy disrespect for the status-quo. We must use forked-tongue thinking to pull from both ends. In a yin-yang way, we must acknowledge how we got here, and push for new thinking to create the future.

Mike Shipulski

Mike Shipulski