Archive for October, 2012

Beyond Dead Reckoning

We’re afraid of technology development because it’s risky. And figuring out where to go is the risky part. To figure out where to go companies use several strategies: advance multiple technologies in parallel; ask the customer; or leave it to company leader’s edict. Each comes with its strengths and weaknesses.

We’re afraid of technology development because it’s risky. And figuring out where to go is the risky part. To figure out where to go companies use several strategies: advance multiple technologies in parallel; ask the customer; or leave it to company leader’s edict. Each comes with its strengths and weaknesses.

I think the best way to figure out where to go is to figure out where you are. And the best way to do that is data-driven S-curve analysis.

To collect data, look to your most recent product launches, say five, and characterize them using a goodness-to-cost ratio. (Think miles per gallon for your technology.) Then plot them chronologically and see how the goodness ratio has evolved – flat, slow growth, steep growth, or decline. The shape of the curve positions your technology within the stages of the S-curve and its location triangulated with contextual clues. You know where you are so you can figure out where to go.

Here’s what the stages feel like and what to do when you’re in them:

Stage 1: Infancy – New physics are used to deliver a known function, but it’s not ready for commercialization. This is like early days of the gasoline-electric hybrid vehicles, where the physics of internal combustion was combined with the physics of batteries. In Stage 1 the elements of the overall system are established, like when Honda developed its first generation Honda Insight and GM its EV1. Prototypes are under test, and they work okay, but not great. In Stage 1, goodness-to-cost is lower than existing technologies (and holding), but the bet is when they mature goodness-to-cost will be best on the planet.

If your previous products were Stage 4 (Maturity) or Stage 5 (Decline), your new project should be in Stage 1. If your existing project is in Stage 1, focus on commercialization. If all your previous projects were (are) in Stage 1, you should focus on commercializing one (moving to Stage 2) at the expense of starting a new one.

Stage 2: Transitional – A product is launched in the market and there is intense competition with existing technologies. In Stage 2, several versions of new technology are introduced (Prius, Prius pluggable, GM’s Volt, Nissan Leaf), and they fight it out. Goodness-to-cost is still less than existing technologies, but there’s some element of the technology that’s attractive. For electric vehicles, think emissions.

If your previous products were Stage 4 (Maturity) or Stage 5 (Decline) and your current project just transitioned from Stage 1, you’re in the right place. In Stage 2, fill gaps in functionality; increase controllability – better controls to improve battery performance; and develop support infrastructure -electric fueling stations.

Stage 3: Growth – Goodness-to-cost increases rapidly, and so do sales. (I think most important for an electric vehicle is miles per charge.)

If you’re in Stage 3, it’s time to find new applications – e.g., electric motorcycles, or shorten energy flow paths – small electric motors at the wheels.

Stage 4: Maturity – The product hits physical limits – flat miles per gallon; hits limits in resources – fossil fuels; hits economic limits – costly carbon fiber body panels to reduce weight; or there’s rapid growth in harmful factors – air pollution.

If you’re in Stage 4, in the short term add auxiliary functions – entertainment systems, mobile hotspot, heated steering wheel, heated washer fluid; or improve aesthetics – like the rise of the good looking small coupe. In the long term, start a Stage 1 project to move to new physics – hydrogen fuel cells.

Stage 5: Decline – New and more effective systems have entered their growth stage – Nissan Leaf outsells Ford pickup trucks.

If you’re in Stage 5, long ago you should have started at Stage 1 project – new physics. If you haven’t, it may be too late.

S-curve analysis guides, but doesn’t provide all the answers. That said, it’s far more powerful than rock-paper-scissors.

(This thinking was blatantly stolen from Victor Fey’s training on Advanced S-Curve Analysis. Thank you, Victor.)

More Risk, Less Consequence

WHY? To grow sales in existing markets and create sales in new markets.

WHY? To grow sales in existing markets and create sales in new markets.

WHAT? Create innovative technologies and design products with more function and less cost.

HOW? Educate the engineering engine.

This is easier said than done, because for years we’ve set one-sided expectations – new products must work and timelines must be met – and driven risk tolerance out of our engineering engine. Now it’s time to inject it back in.

The message – Our thinking must change. We must take more risk, but do it safely by reducing negative consequences of risk.

To reduce negative consequences of risk, we must learn to localize risk through the narrowest and deepest problem definition, and learn to secure the launch so it’s safe to try new things.

We must do more up-front technology work, but learn to do it far more narrowly and deeply. We must learn to hold ourselves accountable to rigorous problem definition, and we must put our best people on technology projects.

To focus creativity we must learn to set seemingly unrealistic time constraints; to focus our actions we can look to a powerful mantra – spend a little, learn a lot.

The trouble with new thinking is it takes new thinking. If you don’t have it, go get it. If you already have it, figure out why you haven’t used it.

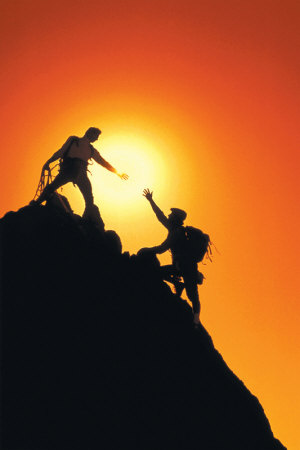

The Pilgrimage of Change

The pilgrimage of change is hard.

The pilgrimage of change is hard.

Before we start, we must believe there’s a way to get there.

Before that, we must believe in the goodness of the destination.

Before that, we must believe there’s a destination.

Before that, we must want something different.

Before that, we must see things as they are.

Before that, we must want to understand.

Before that, we must be curious.

And to do that, we must believe in ourselves.

The Archeologist Technologist

Archeologists look back to see what was; they scratch the ground to find what the past left behind; then they study their bounty and speculate backward in time.

Archeologists look back to see what was; they scratch the ground to find what the past left behind; then they study their bounty and speculate backward in time.

But what makes a good archeologist? In a word – belief. Archeologists must believe there’s something out there, something under the dirt waiting for them. Sure, they use their smarts to choose the best place to dig and dig with the best tools, but they know something’s out there and have a burning desire to find it. The first rule of archeology – don’t dig, don’t find.

There’s almost direct overlap between archeologists and technologists, with one difference – where archeologists dig to define the past and technologists dig to define the future.

Technologists must use their knowledge and experience to dig in the right place and must use the best analytical digging tools. Creativity and knowledge are required to decide where to dig, and once unearthed the technologist must interpret the fragments and decide how to knit together the skeleton. But to me, the most important part of the analogy is belief – for the archeologist belief that fossils are buried under the dirt waiting to be discovered and for the technologist belief that technology is buried and waiting to be discovered.

Before powered flight, the Wright brothers believed technology was out there waiting for them. Their first flight was a monumental achievement, and I don’t want to devalue their work, but think about it – what did they create that wasn’t already there? Yes, they knit together technologies in new ways, but they didn’t create the laws of aerodynamics used for the wings (neither did the earliest aerodynamicists); they did not create the laws of thermodynamics behind the gasoline engine (neither did the early thermodynamicists who measured existing phenomena to make the laws); and they didn’t create the wood for the structure. But what they did do is dig for technology.

Space travel – for most of our history just a dream. But decades before rocket technology, it was all there waiting – the periodic table to make the fuel, the physics to make thrust, and the mechanics to create the structure. Natural resources and technologies were quilted together and processed in new ways, yes. But the technologies, or the rules to create them, were already there waiting to be discovered. And what Goddard did was dig.

The archeologist-technologist analogy can be helpful, but the notion of preexisting technology is way out there – it smacks of predestination in which I don’t believe.

But what I do believe in is belief – belief you have the capability to discover a forward-looking fossil – a future genus that others thought impossible. But only if you dig.

The first rule of technology – don’t dig, don’t find.

A Race To The Top

We all want to increase sales. But to do do this, our products must offer a better value proposition – they must increase the goodness-to-cost ratio. And to do this we increase goodness and decrease cost. (No argument here – this is how everyone does it.) When new technologies mature, we design them in to increase goodness and change manufacturing and materials to reduce cost. Then, we sell. This is the proven cowpath. But there’s a problem.

We all want to increase sales. But to do do this, our products must offer a better value proposition – they must increase the goodness-to-cost ratio. And to do this we increase goodness and decrease cost. (No argument here – this is how everyone does it.) When new technologies mature, we design them in to increase goodness and change manufacturing and materials to reduce cost. Then, we sell. This is the proven cowpath. But there’s a problem.

The problem is everyone is thinking this way. You’re watching/developing the same technologies as your competitors; improving the same manufacturing processes; and trying the same materials. On its own, this a recipe for hyper-competition. But with the sinking economy driving more focus on fewer consumers, price is the differentiator. With this cowpath it’s a race to the bottom.

But there’s a better way where there are no competitors and millions (maybe billions) of untapped consumers clamoring for new products. Yes, it’s based on the time-tested method of improving the goodness-to-cost ratio, but there’s a twist – instead of more it’s less. The ratio is increased with less goodness and far less cost. Since no one in their right mind will take this less-with-far-less approach, there is no competition – it’s just you. And because you will provide less goodness, you must sell where others don’t – into the untapped sea of yet-to-be consumers of developing world. With less-with-far-less it’s a race to the top.

Technology is the most important element of less-with-far-less. By reducing some goodness requirements and dropping others all together, immature technologies become viable. You can incorporate fledgeling technologies sooner and commercialize products with their unreasonably large goodness-to-cost ratios. The trick – think less output and narrow-banded goodness.

Immature technologies have improved goodness-to-cost ratios (that’s why we like them), but their output is low. But when a product is designed to require less output, previously immature technologies become viable. Sure, there’s a little less goodness, but the cost structure is far less – just right for the developing world.

Immature technologies are more efficient and smaller, but their operating range is small. But when a product is designed to work within a narrow band of goodness, technologies become viable sooner. Yes, the product does less, but the cost structure is far less – a winning combination for the developing world.

Less-with-far-less makes the product fit the technology – that’s not the hard part. And less-with-far-less makes the product fit the developing world – not hard. In our all-you-can-eat world, where more is seen as the only way, we can’t comprehend how less can win the race to the top. The hard part is less.

Less-with-far-less is not limited by technology or market – it’s limited because we can’t see less as more.

Mike Shipulski

Mike Shipulski