Posts Tagged ‘DFMA Culture’

Some Ifs and Thens To Get You Through Your Day

If you didn’t get what you wanted, why not try wanting what you got?

If you didn’t get what you wanted, why not try wanting what you got?

If the timing isn’t right, what can you change so it is right?

If it could get you in trouble, might you be on to something?

If it’s impossible, don’t bother.

If it’s easy, let someone else do it.

If there’s no possibility of bad things, there’s no possibility of magic.

If you need trust but have not yet secured it, declare failure and do something else.

If there is no progress, don’t push. Move the blocking agent out of the way.

If you don’t know where the cost is, you can’t design it out.

If the timing isn’t right, why didn’t you do it sooner?

If the project went flawlessly, you didn’t try to do anything meaningful.

If you know some people won’t like it, isn’t that reason enough to do it?

If it’s almost impossible, give it a go.

If it’s easy, teach someone else to do it.

If you don’t know where the waste is, you can’t get rid of it.

If you don’t need trust, it’s the perfect time to build it.

If you try the hardest thing first and it doesn’t work, at least you avoid wasting time on the easy stuff.

If you don’t know the number of parts in your product, you have too many.

If the product came out perfectly, you took too long.

If you don’t give it a go, how can you know it’s impossible?

If trust is in short supply, supply it.

If it’s easy, do something else.

If forgiveness is so much better than permission, why do we like to do things under the radar?

If bad things didn’t happen, try harder next time.

Image credit — Gabriel Caparó

It’s not so easy to move manufacturing work back to the US.

I hear it’s a good idea to move manufacturing work back to the US.

Before getting into what it would take to move manufacturing work back to the US, I think it’s important to understand why manufacturing companies moved their work out of the US. Simply put, companies moved their work out of the US because their accounting systems told them they would make more money if they made their products in countries with lower labor costs. And now that labor costs have increased in these no longer “low-cost countries”, those same accounting systems think there’s more money to be made by bringing manufacturing back to the US.

At a low level of abstraction, manufacturing, as a word, is about making discrete parts like gears, fenders, and tires using machines like gear shapers, stamping machines, and injection molding machines. The cost of manufacturing the parts is defined by the cost of the raw material, the cost of the machines, the cost of energy to power the machines, the cost of the factory, and the cost of the people to run the machines. And then there’s assembly, which, as a word, is about putting those discrete parts together to make a higher-level product. Where manufacturing makes the gears, fenders, and tires, assembly puts them together to make a car. And the cost of assembly is defined by the cost of the factory, the cost of fixtures, and the cost of the people to assemble the parts into the product. And the cost of the finished product is the sum of the cost of making the parts (manufacturing) and the cost of putting them together (assembly).

It seems pretty straightforward to make more money by moving the manufacturing of discrete parts back to the US. All that has to happen is to find some empty factory space, buy new machines, land them in the factory, hire the people to run the machines, train them, source the raw material, hire the manufacturing experts to reinvent/automate the manufacturing process to reduce cycle time and reduce labor time and then give them six months to a year to do that deep manufacturing work. That’s quite a list because there’s little factory space available that’s ready to receive machines, the machines cost money, there are few people available to do manufacturing work, the cost to train them is high (and it takes time and there are no trained trainers). But the real hurdles are the deep work required to reinvent/automate the process and the lack of manufacturing experts to do that work. The question you should ask is – Why does the manufacturing process have to be reinvented/automated?

There’s a dirty little secret baked into the accounting systems’ calculations. The cost accounting says there can be no increased profit without reducing the time to make the parts and reducing the labor needed to make them. If the work is moved from country A to country B and the costs (cycle time, labor hours, labor rate) remain constant, the profit remains constant. Simply moving from country A to country B does nothing. Without the deep manufacturing work, profits don’t increase. And if your country doesn’t have the people with the right expertise, that deep manufacturing work cannot happen.

And the picture is similar for moving assembly work back to the US. All that has to happen is to find empty factory space, hire and train people to do the assembly work, reroute the supply chains to the new factory, redesign the product so it can be assembled with an automated assembly line, hire/train the people to redesign the product so it can be assembled in an automated way, design the new automated assembly process, build it, test it, hire/train the automated assembly experts to do that work, hire the people to support and run the automated assembly line, and pay for the multi-million-dollar automated assembly line. And the problems are similar. There’s not a lot of world-class factory space, there are few people available to run the automated assembly line, and the cost of the automated assembly line is significant. But the real problems are the lack of experts to redesign the product for automated assembly and the lack of expertise to design, build, and validate the assembly line. And here are the questions you should ask – Why do we need to automate the assembly process and why does the product have to be redesigned to do that?

It’s that dirty little secret rearing its ugly head again. The cost accounting says there can be no increased profit without reducing the labor to assemble the parts. make them. If the work is moved from country A to country B and the assembly costs (labor hours, labor rate) remain constant, the profit remains constant. Simply moving from country A to country B does nothing. Without deep design work (design for automated assembly) and ultra-deep automated assembly work, profits don’t increase. And if your country doesn’t have the people with the right expertise, that deep design and automated assembly work cannot happen.

If your company doesn’t have the time, money, and capability to reinvent/automate manufacturing processes, it’s a bad idea to move manufacturing work back to the US. It simply won’t work. Instead, find experts who can help you develop/secure the capability to reinvent/automate manufacturing processes to reduce the cost of manufacturing.

If your company doesn’t have the time, money, and capability to design products for automated assembly and to design, build, and validated automated assembly systems, it’s a bad idea to move assembly work back to the US. It, too, simply won’t work. Instead, partner with experts who know how to do that work so you can reduce the cost of assembly.

The best time to design cost out of our products is now.

With inflation on the rise and sales on the decline, the time to reduce costs is now.

With inflation on the rise and sales on the decline, the time to reduce costs is now.

But before you can design out the cost you’ve got to know where it is. And the best way to do that is to create a Pareto chart that defines product cost for each subassembly, with the highest cost subassemblies on the left and the lowest cost on the right. Here’s a pro tip – Ignore the subassemblies on the right.

Use your costed Bill of Materials (BOMs) to create the Paretos. You’ll be told that the BOMs are wrong (and they are), but they are right enough to learn where the cost is.

For each of the highest-cost subassemblies, create a lower-level Pareto chat that sorts the cost of each piece-part from highest to lowest. The pro tip applies here, too – Ignore the parts on the right.

Because the design community designed in the cost, they are the ones who must design it out. And to help them prioritize the work, they should be the ones who create the Pareto charts from the BOMs. They won’t like this idea, but tell them they are the only ones who can secure the company’s future profits and buy them lots of pizza.

And when someone demands you reduce labor costs, don’t fall for it. Labor cost is about 5% of the product cost, so reducing it by half doesn’t get you much. Instead, make a Pareto chart of part count by subassembly. Focus the design effort on reducing the part count of subassemblies on the left. Pro tip – Ignore the subassemblies on the right. The labor time to assemble parts that you design out is zero, so when demand returns, you’ll be able to pump out more products without growing the footprint of the factory. But, more importantly, the cost of the parts you design out is also zero. Designing out the parts is the best way to reduce product costs.

Pro tip – Set a cost reduction goal of 35%. And when they complain, increase it to 40%.

In parallel to the design work to reduce part count and costs, design the test fixtures and test protocols you’ll use to make sure the new, lower-cost design outperforms the existing design. Certainly, with fewer parts, the new one will be more reliable. Pro tip – As soon as you can, test the existing design using the new protocols because the only way to know if the new one is better is to measure it against the test results of the old one.

And here’s the last pro tip – Start now.

Image credit — aisletwentytwo

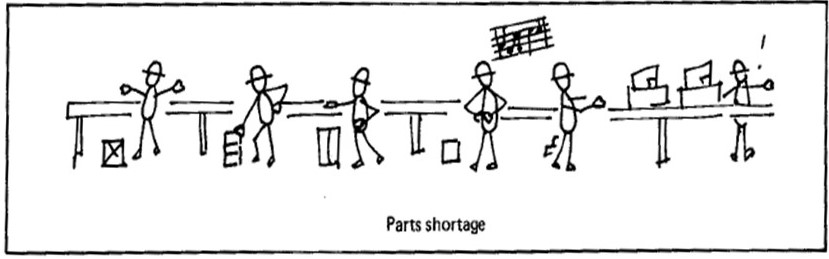

Supply chains don’t have to break.

We’ve heard a lot about long supply chains that have broken down, parts shortages, and long lead times. Granted, supply chains have been stressed, but we’ve designed out any sort of resiliency. Our supply chains are inflexible, our products are intolerant to variation and multiple sources for parts, and our organizations have lost the ability to quickly and effectively redesign the product and the parts to address issues when they arise. We’ve pushed too hard on traditional costing and have not placed any value on flexibility. And we’ve pushed too hard on efficiency and outsourced our design capability so we can no longer design our way out of problems.

We’ve heard a lot about long supply chains that have broken down, parts shortages, and long lead times. Granted, supply chains have been stressed, but we’ve designed out any sort of resiliency. Our supply chains are inflexible, our products are intolerant to variation and multiple sources for parts, and our organizations have lost the ability to quickly and effectively redesign the product and the parts to address issues when they arise. We’ve pushed too hard on traditional costing and have not placed any value on flexibility. And we’ve pushed too hard on efficiency and outsourced our design capability so we can no longer design our way out of problems.

Our supply chains are inflexible because that’s how we designed them. The products cannot handle parts from multiple suppliers because that’s how we designed them. And the parts cannot be made by multiple suppliers because that’s how we designed them.

Now for the upside. If we want a robust supply chain, we can design the product and the parts in a way that makes a robust supply chain possible. If we want the flexibility to use multiple suppliers, we can design the product and parts in a way that makes it possible. And if we want the capability to change the product to adapt to unforeseen changes, we can design our design organizations to make it possible.

There are established tools and methods to help the design community design products in a way that creates flexibility in the supply chain. And those same tools and methods can also help the design community create products that can be made with parts from multiple suppliers. And there are teachers who can help rebuild the design community’s muscles so they can change the product in ways to address unforeseen problems with parts and suppliers.

How much did it cost you when your supply chain dried up? How much did it cost you the last time a supplier couldn’t deliver your parts? How much did it cost you when your design community couldn’t redesign the product to keep the assembly line running? Would you believe me if I told you that all those costs are a result of choices you made about how to design your supply chain, your product, your parts, and your engineering community?

And would you believe me if I told you could make all that go away? Well, even if you don’t believe me, the potential upside of making it go away is so significant you may want to look into it anyway.

Image credit — New Manufacturing Challenge, Suzaki, 1987.

The Threshold Of Uncertainty

Our threshold for uncertainty is too low.

Our threshold for uncertainty is too low.

Early in projects, even before the first prototype is up and running, you know what the product must do, what it will cost, and, most problematic, when you’ll be done. Independent of work content, level of newness, and workloads, there’s no uncertainty in your launch date. It’s etched in stone and the consequences are devastating.

A zero tolerance policy on uncertainty forces irrational behavior. As soon as possible, engineering gets something running in the lab, and then doesn’t want to change it because there’s no time. The prototype is almost impossible to build and is hypersensitive to normal process variation, but these issues are not addressed because there’s no time. Everyone agrees it’s important to fix it, and agrees to fix it after launch, but that never happens because the next project is already late before it starts. And the death cycle repeats project after project.

The root cause of this mess is the mistaken porting of manufacturing’s zero uncertainly mindset into design. The thinking goes like this – lean and Six Sigma have achieved magical success in manufacturing by eliminating uncertainty, so let’s do it in product design and achieve similar results. This is a fundamental mistake as the domains are fundamentally different.

In manufacturing the same product is made day-in and day-out – no uncertainty; in product design no two product development efforts are the same and there’s lots of stuff that’s done for the first time – uncertainty by definition. In manufacturing there’s a revision controlled engineering drawing that defines the right answer (the geometry and the material) – make it like the picture and it’s all good; in product design the material is chosen from many candidates and the geometry is created from scratch – the picture is created from nothing. By definition there’s more inherent uncertainty in product design, and to tighten the screws and fix the launch date at the start is inappropriate.

Design engineers must feel like there’s enough time to try new things because new products that provide new functionality require new technologies, new materials, and new geometries. With new comes inherent uncertainty, but there are ways to manage it.

To hold the timeline, give on the specification and cost. Design as fast as you can until you run out of time then launch. The product won’t work as well as you’d like and it will cost more than you’d like, but you’ll hit the schedule. A good way to do this is to de-feature a subassembly to reduce design time, and possibly reduce cost. Or, reuse a proven subassembly to reduce design time – take a hit in cost, but hit the timeline. The general idea – hold schedule but flex on performance and cost.

It feels like sacrilege to admit that something’s got to give, but it’s the truth. You’ve seen how it goes when you edict (in no uncertain terms) that the timeline will be met and there’ll be no give on performance and cost. It hasn’t worked, and it won’t – the inherent uncertainty of product design won’t let it.

Accept the uncertainty; be one with it; and manage it. It’s the only way.

A Recipe for Unreasonable Profits

There’s an unnatural attraction to lean – a methodology to change the value stream to reduce waste. And it’s the same with Design for Manufacturing (DFM) – a methodology to design out cost of your piece-parts. The real rain maker is Design for Assembly (DFA) which eliminates parts altogether (50% reductions are commonplace.) DFA is far more powerful.

There’s an unnatural attraction to lean – a methodology to change the value stream to reduce waste. And it’s the same with Design for Manufacturing (DFM) – a methodology to design out cost of your piece-parts. The real rain maker is Design for Assembly (DFA) which eliminates parts altogether (50% reductions are commonplace.) DFA is far more powerful.

The cost for a designed out part is zero. Floor space for a designed out part is zero. Transportation cost for a designed out part is zero. (Can you say Green?) From a lean perspective, for a designed out part there is zero waste. For a designed out part the seven wastes do not apply.

Here’s a recipe for unreasonable profits:

Design out half the parts with DFA. For the ones that remain, choose the three highest cost parts and design out the cost. Then, and only then, do lean on the manufacturing processes.

For a video version of the post, see this link: (Video embedded below.)

A Recipe for Unreasonable Profits.

We must broaden “Design”

Design is typically limited to function – what it does – and is done by engineering (red team). Manufacturing is all about how to make it and is done by manufacturing (blue team). Working separately there is local optimization. We must broad to design to include both – red and blue. Working across red-blue boundaries creates magic. This magic can only be done by the purple team.

Below is my first video post. I hope to do more. Let me know what you think.

The Improvement Mindset

![]()

![]()

![]()

![]()

Improvement is good; we all want it. Whether it’s Continuous Improvement (CI), where goodness, however defined, is improved incrementally and continually, or Discontinuous Improvement (DI), where goodness is improved radically and steeply, we want it. But, it’s not enough to want it.

Improvement is good; we all want it. Whether it’s Continuous Improvement (CI), where goodness, however defined, is improved incrementally and continually, or Discontinuous Improvement (DI), where goodness is improved radically and steeply, we want it. But, it’s not enough to want it.

How do we create the Improvement Mindset, where the desire to make things better is a way of life? The traditional non-answer goes something like this: “Well, you know, a lot of diverse factors have to come together in a holistic way to make it happen. It takes everyone pulling in the same direction.” Crap. If I had to pick the secret ingredient that truly makes a difference it’s this:

a

People with the courage to see things as they are.

a

People who can hold up the mirror and see warts as warts and problems as problems – they’re the secret ingredient. No warts, no improvement. No problems, no improvement. And I’m not talking about calling out the benign problems. I’m talking about the deepest, darkest, most fundamental problems, problems some even see as strengths, core competencies, or even as competitive advantage. Problems so fundamental, and so wrong, most don’t see them, or dare see them.

The best-of-the-best can even acknowledge warts they themselves created. Big medicine. It’s easy to see warts or problems in others’ work, but it takes level 5 courage to call out the ugliness you created. Nothing is off limits with these folks, nothing left on the table. Wide open, no-holds-barred, full frontal assault on the biggest, baddest crap your company has to offer. It’s hard to do. Like telling a mother her baby is ugly – it’s one thing to think the baby is ugly, but it’s another thing altogether to open up your mouth and acknowledge it face-to-face, especially if you’re the father. (Disclaimer: To be clear, I do not recommend telling your spouse your new baby is ugly. Needless to say, some things MUST be left unsaid.)

It’s not always easy to be around the courageous souls willing to jeopardize their careers for the sake of improvement. And it takes level 5 courage to manage them. But, if you want your company to contract a terminal case of the Improvement Mindset, it’s a price you must pay.

Click this link for information on Mike’s upcoming workshop on Systematic DFMA Deployment

What is a DFMA Culture?

What is a DFMA Culture? (.pdf, 1 page)

John Gilligan of Boothroyd Dewhurst, Inc. asked me to describe a DFMA culture. Here is my description:

At the highest level, a strong DFMA culture is founded on the understanding that The Product strongly governs most everything in a company. Product function governs what customers will pay for; product structure governs a company’s organizational structure; and product features, attributes and materials govern cost. Stepping down one level, the DFMA culture is founded on the understanding that product function and product cost are coupled – they are two sides of the same coin – and are considered together when doing DFMA. Read the rest of this entry »

Mike Shipulski

Mike Shipulski