Archive for March, 2015

Purposeful Violation of the Prime Directive

In Star Trek, the Prime Directive is the over-arching principle for The United Federation of Planets. The intent of the Prime Directive is to let a sentient species live in accordance with its normal cultural evolution. And the rules are pretty simple – do whatever you want as long as you don’t violate the Prime Directive. Even if Star Fleet personnel know the end is near for the sentient species, they can do nothing to save it from ruin.

In Star Trek, the Prime Directive is the over-arching principle for The United Federation of Planets. The intent of the Prime Directive is to let a sentient species live in accordance with its normal cultural evolution. And the rules are pretty simple – do whatever you want as long as you don’t violate the Prime Directive. Even if Star Fleet personnel know the end is near for the sentient species, they can do nothing to save it from ruin.

But what does it mean to “live in accordance with the normal cultural evolution?” To me it means “preserve the status quo.” In other words, the Prime Directive says – don’t do anything to challenge or change the status quo.

Though today’s business environment isn’t Star Trek and none of us work for Star Fleet, there is a Prime Directive of sorts. Today’s Prime Directive deals not with sentient species and their cultures but with companies and their business models, and its intent is to let a company live in accordance with the normal evolution of its business model. And the rules are pretty simple – do whatever you want as long as you don’t violate the Prime Directive. Even if company leaders know the end is near for the business model, they can do nothing to save it from ruin.

Business models, and their decrepit value propositions propping them up, don’t evolve. They stay just as they are. From inside the company the business model and value proposition are the very things that provide sustenance (profitability). They are known and they are safe – far safer than something new – and employees defend them as diligently as Captain Kirk defends his Prime Directive. With regard to business models, “to live in accordance with its natural evolution” is to preserve the status quo until it goes belly up. Today’s Prime Directive is the same as Star Trek’s – don’t do anything to challenge or change the status quo.

Innovation brings to life things that are novel, useful, and successful. And because novel is the same as different, innovation demands complete violation of today’s Prime Directive. For innovators to be successful, they must blow up the very things the company holds dear – the declining business model and its long-in-the-tooth value proposition.

The best way to help innovators do their work is to provide them phasers so they can shoot those in the way of progress, but even the most progressive HR departments don’t yet sanction phasers, even when set to “stun”. The next best way is to educate the company on why innovation is important. Company leaders must clearly articulate that business models have a finite life expectancy (measured in years, not decades) and that it’s the company’s obligation to disrupt and displace it.them.

The Prime Directive has a valuable place in business because it preserves what works, but it needs to be amended for innovation. And until an amendment is signed into law, company leaders must sanction purposeful violation of the Prime Directive and look the other way when they hear the shrill ring a phaser emanating from the labs.

Image credit – svenwerk

Systematic Innovation

Innovation is a journey, and it starts from where you are. With a systematic approach, the right information systems are in place and are continuously observed, decision makers use the information to continually orient their thinking to make better and faster decisions, actions are well executed, and outcomes of those actions are fed back into the observation system for the next round of orientation. With this method, the organization continually learns as it executes – its thinking is continually informed by its environment and the results of its actions.

Innovation is a journey, and it starts from where you are. With a systematic approach, the right information systems are in place and are continuously observed, decision makers use the information to continually orient their thinking to make better and faster decisions, actions are well executed, and outcomes of those actions are fed back into the observation system for the next round of orientation. With this method, the organization continually learns as it executes – its thinking is continually informed by its environment and the results of its actions.

To put one of these innovation systems in place, the first step is to define the group that will make the decisions. Let’s call them the Decision Group, or DG for short. (By the way, this is the same group that regularly orients itself with the information steams.) And the theme of the decisions is how to deploy the organization’s resources. The decision group (DG) should be diverse so it can see things from multiple perspectives.

The DG uses the company’s mission and growth objectives as their guiding principles to set growth goals for the innovation work, and those goals are clearly placed within the context of the company’s mission.

The first action is to orient the DG in the past. Resources are allocated to analyze the product launches over the past ten years and determine the lines of ideality (themes of goodness, from the customers’ perspective). These lines define the traditional ideality (traditional themes of goodness provided by your products) are then correlated with historical profitability by sales region to evaluate their importance. If new technology projects provide value along these traditional lines, the projects are continuous improvement projects and the objective is market share gain. If they provide extreme value along traditional lines, the projects are of the dis-continuous improvement flavor and their objective is to grow the market. If the technology projects provide value along different lines and will be sold to a different customer base, the projects could be disruptive and could create new markets.

The next step is to put in place externally focused information streams which are used for continuous observation and continual orientation. An example list includes: global and regional economic factors, mergers/acquisitions/partnerships, legal changes, regulatory changes, geopolitical issues, competitors’ stock price and quarterly updates, and their new products and patents. It’s important to format the output for easy visualization and to make collection automatic.

Then, internally focused information streams are put in place that capture results from the actions of the project team and deliver them, as inputs, for observation and orientation. Here’s an example list: experimental results (technology and market-centric), analytical results (technical and market), social media experiments, new concepts from ideation sessions (IBEs), invention disclosures, patent filings, acquisition results, product commercialization results and resulting profits. These information streams indicate the level of progress of the technology projects and are used with the external information streams to ground the DG’s orientation in the achievements of the projects.

All this infrastructure, process, and analysis is put in place to help the DG make good (and fast) decisions about how to allocate resources. To make good decisions, the group continually observes the information streams and continually orients themselves in the reality of the environment and status of the projects. At this high level, the group decides not how the project work is done, rather what projects are done. Because all projects share the same resource pool, new and existing projects are evaluated against each other. For ongoing work the DG’s choice is – stop, continue, or modify (more or less resources); and for new work it’s – start, wait, or never again talk about the project.

Once the resource decision is made and communicated to the project teams, the project teams (who have their own decision groups) are judged on how well the work is executed (defined by the observed results) and how quickly the work is done (defined by the time to deliver results to the observation center.)

This innovation system is different because it is a double learning loop. The first one is easy to see – results of the actions (e.g., experimental results) are fed back into the observation center so the DG can learn. The second loop is a bit more subtle and complex. Because the group continuously re-orients itself, it always observes information from a different perspective and always sees things differently. In that way, the same data, if observed at different times, would be analyzed and synthesized differently and the DG would make different decisions with the same data. That’s wild.

The pace of this double learning loop defines the pace of learning which governs the pace of innovation. When new information from the streams (internal and external) arrive automatically and without delay (and in a format that can be internalized quickly), the DG doesn’t have to request information and wait for it. When the DG makes the resource-project decisions it’s always oriented within the context of latest information, and they don’t have to wait to analyze and synthesize with each other. And when they’re all on the same page all the time, decisions don’t have to wait for consensus because it already has. And when the group has authority to allocate resources and chooses among well-defined projects with clear linkage to company profitability, decisions and actions happen quickly. All this leads to faster and better innovation.

There’s a hierarchical set of these double learning loops, and I’ve described only the one at the highest level. Each project is a double learning loop with its own group of deciders, information streams, observation centers, orientation work and actions. These lower level loops are guided by the mission of the company, goals of the innovation work, and the scope of their projects. And below project loops are lower-level loops that handle more specific work. The loops are fastest at the lowest levels and slowest at the highest, but they feed each other with information both up the hierarchy and down.

The beauty of this loop-based innovation system is its flexibility and adaptability. The external environment is always changing and so are the projects and the people running them. Innovation systems that employ tight command and control don’t work because they can’t keep up with the pace of change, both internally and externally. This system of double loops provides guidance for the teams and sufficient latitude and discretion so they can get the work done in the best way.

The most powerful element, however, is the almost “living” quality of the system. Over its life, through the work itself, the system learns and improves. There’s an organic, survival of the fittest feel to the system, an evolutionary pulse, that would make even Darwin proud.

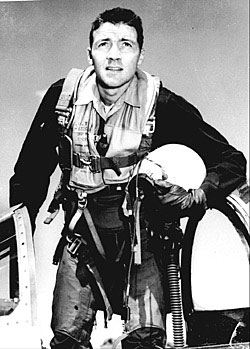

But, really, it’s Colonel John Boyd who should be proud because he invented all this. And he called it the OODA loop. Here’s his story – Boyd: The Fighter Pilot Who Changed the Art of War.

Where possible, I have used Boyd’s words directly, and give him all the credit. Here is a list of his words: observe, orient, decide, act, analyze-synthesize, double loop, speed, organic, survival of the fittest, evolution.

Image attribution – U.S. Government [public domain]. by wikimedia commons.

The Certainty of Uncertainty

When the output cannot be predicted, that’s uncertainty. And if there’s one thing to be certain of it’s uncertainty is always part of the equation.

When the output cannot be predicted, that’s uncertainty. And if there’s one thing to be certain of it’s uncertainty is always part of the equation.

With uncertainty, the generally accepted practice is minimization, and the method of choice is to control inputs. The best example is a high volume manufacturing process where inputs are controlled to reduce variation of the output (or reduce the uncertainty around goodness). Six Sigma tightens the screws on suppliers, materials, process steps, assembly tools and measurement gear so the first car off the production line is the same as the last one. That way, customers are certain to get what they’re promised. Minimization of uncertainty makes a lot of sense in the manufacturing analogy.

But there’s no free lunch with uncertainty, and the price of all this control is inflexibility. The manufacturing process can do only what it’s designed to do – to make what it was designed to make – and no more. And it can provide certainty of output only over a finite input range. Within the appropriate range of inputs there is certainty, but outside that range there is uncertainty. Even in the most well defined, highly controlled processes where great expense is taken to reduce uncertainty, there is uncertainty. Even the best automotive assembly lines can be disrupted by things like tsunamis, earthquakes, epidemics and labor strikes (100% certainty doesn’t exist). But still, in the manufacturing context minimization of uncertainty is a sound strategy.

When the intent of a process is to do things that have never been done and to bring new things to life, minimization of uncertainty is directionally incorrect. Said a different way, creativity and innovation demand uncertainty. More clearly – if there’s no uncertainty in the trenches, there’s no innovation.

The manufacturing analogy has been pushed too far from the factory. Just as Six Sigma has eliminated variation (and uncertainty) from things it shouldn’t (creativity work), lean and its two uncertainty killers (best practices and standard work) have been jammed into the gears of innovation and gummed up the works.

Standard work and best practices were invented to reduce variation in how work is done with the objective of, you guessed it, reducing uncertainty. The idea is to continuously improve and converge on the right recipe (sequence of operations or process steps) so the work is done the same way every-day-all-day. By definition, innovation work (the process steps) is never done the same way twice. The rule with best practices is simple – it should be reused every time there’s a need for that exact process. That makes sense. But it makes no sense to use a best practice when a process is done for the first time.

[Okay, the purists say that all transactional elements of innovation should follow standard work, and theoretically that’s right. But practically, the backwash of standard work, even when applied to transactional work, infects the psyche of the innovator and reduces uncertainty where uncertainty should be bolstered.]

Uncertainty is an important part of innovation, but it should not be maximized (it’s as inappropriate as minimizing). And there is no best practice for calculating the right amount. To strike a good balance, hold onto the fact that uncertainty and flexibility are a matched pair, and when doing something for the first time flexibility is a friend. And when standard work and best practices are imposed in the name of innovation efficiency, remember it’s far more important to have innovation effectiveness.

Image credit – NMK Photography

Clarity is King

It all starts and ends with clarity. There’s not much to it, really. You strip away all the talk and get right to the work you’re actually doing. Not the work you should do, want to do, or could do. The only thing that matters is the work you are doing right now. And when you get down to it, it’s a short list.

It all starts and ends with clarity. There’s not much to it, really. You strip away all the talk and get right to the work you’re actually doing. Not the work you should do, want to do, or could do. The only thing that matters is the work you are doing right now. And when you get down to it, it’s a short list.

There’s a strong desire to claim there’s a ton of projects happening all at once, but projects aren’t like that. Projects happen serially. Start one, finish one is the best way. Sure it’s sexy to talk about doing projects in parallel, but when the rubber meets the road, it’s “one at time” until you’re done.

The thing to remember about projects is there’s no partial credit. If a project is half done, the realized value is zero, and if a project is 95% done, the realized value is still zero (but a bit more frustrating). But to rationalize that we’ve been working hard and that should count for something, we allocate partial credit where credit isn’t due. This binary thinking may be cold, but it’s on-the-mark. If your new product is 90% done, you can’t sell it – there is no realized value. Right up until it’s launched it’s work in process inventory that has a short shelf like – kind of like ripe tomatoes you can’t sell. If your competitor launches a winner, your yet-to-see-day light product over-ripens.

Get a pencil and paper and make the list of the active projects that are fully staffed, the ones that, come hell or high water, you’re going to deliver. Short list, isn’t it? Those are the projects you track and report on regularly. That’s clarity. And don’t talk about the project you’re not yet working on because that’s clarity, too.

Are those the right projects? You can slice them, categorize them, and estimate the profits, but with such a short list, you don’t need to. Because there are only a few active projects, all you have to do is look at the list and decide if they fit with company expectations. If you have the right projects, it will be clear. If you don’t, that will be clear as well. Nothing fancy – a list of projects and a decision if the list is good enough. Clarity.

How will you know when the projects are done? That’s easy – when the resources start work on the next project. Usually we think the project ends when the product launches, but that’s not how projects are. After the launch there’s a huge amount of work to finish the stuff that wasn’t done and to fix the stuff that was done wrong. For some reason, we don’t want to admit that, so we hide it. For clarity’s sake, the project doesn’t end until the resources start full-time work on the next project.

How will you know if the project was successful? Before the project starts, define the launch date and using that launch data, set a monthly profit target. Don’t use units sold, units shipped, or some other anti-clarity metric, use profit. And profit is defined by the amount of money received from the customer minus the cost to make the product. If the project launches late, the profit targets don’t move with it. And if the customer doesn’t pay, there’s no profit. The money is in the bank, or it isn’t. Clarity.

Clarity is good for everyone, but we don’t behave that way. For some reason, we want to claim we’re doing more work than we actually are which results in mis-set expectations. We all know it’s matter of time before the truth comes out, so why not be clear? With clarity from the start, company leaders will be upset sooner rather than later and will have enough time to remedy the situation.

Be clear with yourself that you’re highly capable and that you know your work better than anyone. And be clear with others about what you’re working on and what you’re not. Be clear about your test results and the problems you know about (and acknowledge there are likely some you don’t know about).

I think it all comes down to confidence and self-worth. Have the courage wear clarity like a badge of honor. You and your work are worth it.

Image credit – Greg Foster

Mike Shipulski

Mike Shipulski