Archive for the ‘Manufacturing Competitiveness’ Category

Seeing Things As They Are

It’s tough out there. Last year we threw the kitchen sink at our processes and improved them, and now last year’s improvements are this year’s baseline. And, more significantly, competition has increased exponentially – there are more eager countries at the manufacturing party. More countries have learned that manufacturing jobs are the bedrock of sustainable economy. They’ve designed country-level strategies and multi-decade investment plans (education, infrastructure, and energy technologies) to go after manufacturing jobs as if their survival depended on them. And they’re not just making, they’re designing and making. Country-level strategies and investments, designing and making, and citizens with immense determination to raise their standard of living – a deadly cocktail. (Have you seen Hyundai’s cars lately?)

It’s tough out there. Last year we threw the kitchen sink at our processes and improved them, and now last year’s improvements are this year’s baseline. And, more significantly, competition has increased exponentially – there are more eager countries at the manufacturing party. More countries have learned that manufacturing jobs are the bedrock of sustainable economy. They’ve designed country-level strategies and multi-decade investment plans (education, infrastructure, and energy technologies) to go after manufacturing jobs as if their survival depended on them. And they’re not just making, they’re designing and making. Country-level strategies and investments, designing and making, and citizens with immense determination to raise their standard of living – a deadly cocktail. (Have you seen Hyundai’s cars lately?)

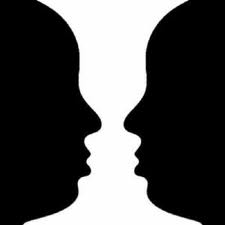

With the wicked couple of competition and profitability goals, we’re under a lot of pressure. And with the pressure comes the danger of seeing things how we want them instead of how they are, like a self-created optical illusion. Here are some likely optical illusion A-B pairs (A – how we want things; B – how they are):

A. Give people more work and more gets done. B. Human output has a physical limit, and once reached less gets done – and spouses get angry. A. Do more projects in parallel to generate more profit. B. Business processes have physical limits, and once reached projects slow and everyone works harder for the same output. A. Add resources to the core project team and more projects get done. B. Add resources to core projects teams and utilization skyrockets for shared resources – waiting time increases for all. A. Use lean in product development (just like in manufacturing) to launch new products better and faster. B. Lean done in product development is absolutely different than in manufacturing, and design engineers don’t take kindly to manufacturing folks telling them how to do their work. A. Through negotiation and price reduction, suppliers can deliver cost reductions year-on-year. B. The profit equation has a physical limit (no profit), and once reached there is no supplier. A. Use lean to reduce product cost by 5%. B. Use DFMA to reduce product cost by 50%.Competition is severe and the pressure is real. And so is the danger to see things as we want them to be. But there’s a simple way to see things as they are: ask the people that do the work. Go to the work and ask the experts. They do the work day-in-day-out, and they know what really happens. They know the details, the pinch points, and the critical interactions.

To see things as they are, check your ego at the door, and go ask the experts – the people that do the work.

Lean and Supply Chain Sensitivity

At every turn, lean has increased profits in the factory. Its best trick is to look at the work through a time lens, see wasted time, and get rid of it.

At every turn, lean has increased profits in the factory. Its best trick is to look at the work through a time lens, see wasted time, and get rid of it.

Work is blocked by problems. You watch the work to spot blockages in the form of piles, otherwise known as inventory. When you find a pile, you know the problem is one operation downstream.

As lean works its magic, inventory is reduced, which decreases carrying costs. More importantly, however, it also reduces the time to see a problem. Whether the problem is related to quality, delivery or resources, everything stops immediately. It’s clear what to fix, and there’s incentive to fix it quickly because with lean, the factory is more sensitive to problems.

What works in the factory will also work in the supply chain, and that’s where lean is going.

Radically Simplify Your Value Stream – Change Your Design

The next level of factory simplification won’t come from your factory. It will come from outside your factory. The next level of simplification will come from upstream savings – your suppliers’ factories – and downstream savings – your distribution system. And this next level of simplification will create radically shorter value streams (from raw materials to customer.)

The next level of factory simplification won’t come from your factory. It will come from outside your factory. The next level of simplification will come from upstream savings – your suppliers’ factories – and downstream savings – your distribution system. And this next level of simplification will create radically shorter value streams (from raw materials to customer.)

To reinvent your value stream, traditional lean techniques – reduction of non-value added (NVA) time through process change – aren’t the best way. The best way is to eliminate value added (VA) time through product redesign – product change. Reduction of VA time generates a massive NVA savings multiple. (Value streams are mostly NVA with a little VA sprinkled in.) At first this seems like backward thinking (It is bit since lean focuses exclusively on NVA.), but NVA time exists only to enable VA time (VA work). No VA time, no associated NVA time.

Value streams are all about parts (making them, counting them, measuring them, boxing them, moving them, and un-boxing them) and products (making, boxing, moving.) The making – touch time, spindle time – is VA time and everything else is VA time. Design out the parts themselves (VA time) and NVA time is designed out. Massive multiple achieved.

But the design community is the only group that can design out the parts. How to get them involved? Not all parts are created equal. How to choose the ones that matter? Value streams cut across departments and companies. How to get everyone pulling together?

Watch the video: link to video. (And embedded below.)

How To Create a Sea of Manufacturing Jobs

It’s been a long slide from greatness for US manufacturing. It’s been downhill since the 70s – a multi-decade slide. Lately there’s a lot of hype about a manufacturing renaissance in the US – re-shoring, on-shoring, right-shoring. But the celebration misguided. A real, sustainable return to greatness will take decades, decades of single-minded focus, coordination, alignment and hard work – industry, government, and academia in it together for the long haul.

It’s been a long slide from greatness for US manufacturing. It’s been downhill since the 70s – a multi-decade slide. Lately there’s a lot of hype about a manufacturing renaissance in the US – re-shoring, on-shoring, right-shoring. But the celebration misguided. A real, sustainable return to greatness will take decades, decades of single-minded focus, coordination, alignment and hard work – industry, government, and academia in it together for the long haul.

To return to greatness, the number of new manufacturing jobs to be created is distressing. 100,000 new manufacturing jobs is paltry. And today there is a severe skills gap. Today there are unfilled manufacturing jobs because there’s no one to do the work. No one has the skills. With so many without jobs it sad. No, it’s a shame. And the manufacturing talent pipeline is dry – priming before filling. Creating a sea of new manufacturing jobs will be hard, but filling them will be harder. What can we do?

The first thing to do is make list of all the open manufacturing jobs and categorize them. Sort them by themes: by discipline, skills, experience, tools. Use the themes to create training programs, train people, and fill the open jobs. (Demonstrate coordinated work of government, industry, and academia.) Then, using the learning, repeat. Define themes of open manufacturing jobs, create training programs, train, and fill the jobs. After doing this several times there will be sufficient knowledge to predict needed skills and proactive training can begin. This cycle should continue for decades.

Now the tough parts – transcending our short time horizon and finding the money. Our time horizon is limited to the presidential election cycle – four years, but the manufacturing rebirth will take decades. Our four year time horizon prevents success. There needs to be a guiding force that maintains consistency of purpose – manufacturing resurgence – a consistency of purpose for decades. And the resurgence cannot require additional money. (There isn’t any.) So who has a long time horizon and money?

The DoD has both – the long term view (the military is not elected or appointed) and the money. (They buy a lot of stuff.) Before you call me a war hawk, this is simply a marriage of convenience. I wish there was, but there is no better option.

The DoD should pull together their biggest contractors (industry) and decree that the stuff they buy will have radically reduced cost signatures and teach them and their sub-tier folks how to get it done. No cost reduction, no contract. (There’s no reason military stuff should cost what it does, other than the DoD contractors don’t know how design things cost effectively.) The DoD should educate their contractors how to design products to reduce material cost, assembly time, supply chain complexity, and time to market and demand the suppliers. Then, demand they demonstrate the learning by designing the next generation stuff. (We mistakenly limit manufacturing to making, when, in fact, radical improvement is realized when we see manufacturing as designing and making.)

The DoD should increase its applied research at the expense of its basic research. They should fund applied research that solves real problems that result in reduced cost signatures, reduce total cost of ownership, and improved performance. Likely, they should fund technologies to improve engineering tools, technologies that make themselves energy independent and new materials. Once used in production-grade systems, the new technologies will spill into non-DoD world (broad industry application) and create new generation products and a sea of manufacturing jobs.

I think this is approach has a balanced time horizon – fill manufacturing jobs now and do the long term work to create millions of manufacturing jobs in the future.

Yes, the DoD is at the center of the approach. Yes, some have a problem with that. Yes, it’s a marriage of convenience. Yes, it requires coordination among DoD, industry, and academia. Yes, that’s almost impossible to imagine. Yes, it requires consistency of purpose over decades. And, yes, it’s the best way I know.

What is Design for Manufacturing and Assembly?

Design for Manufacturing (DFM) is all about reducing the cost of piece-parts. Design for Assembly is all about reducing the cost of putting things together (assembly). What’s often forgotten is that function comes first. Change the design to reduce part cost, but make sure the product functions well. Change the parts (eliminate them) to reduce assembly cost, but make sure the product functions well.

Paradoxically, DFM and DFA are all about function.

Here’s a link to a short video that explains DFM and DFA: link to video. (and embedded below)

Organizationally Challenged – Engineering and Manufacturing

Our organizations are set up in silos, and we’re measured that way. (And we wonder why we get local optimization.) At the top of engineering is the VP of the Red Team, who is judged on what it does – product. At the top of manufacturing is the VP of the Blue Team, who is judged on how to make it – process. Red is optimized within Red and same for Blue, sometimes with competing metrics. What we need is Purple behavior.

Here’s a link to a short video (1:14): Organizationally Challenged

And embedded below:

Let me know what you think.

We must broaden “Design”

Design is typically limited to function – what it does – and is done by engineering (red team). Manufacturing is all about how to make it and is done by manufacturing (blue team). Working separately there is local optimization. We must broad to design to include both – red and blue. Working across red-blue boundaries creates magic. This magic can only be done by the purple team.

Below is my first video post. I hope to do more. Let me know what you think.

The Supreme Court of Technology

The Founding Fathers got it right with three branches: legislative to make laws; judicial to interpret laws; and executive to enforce them. Back then it was all about laws, and the system worked.

The Founding Fathers got it right with three branches: legislative to make laws; judicial to interpret laws; and executive to enforce them. Back then it was all about laws, and the system worked.

What the Founding Fathers could not realize was there was a powerful, pre-chrysalis force more powerful than laws, whose metamorphosis would exploit a gap in the three branch system. Technology has become a force more powerful than laws, and needs its own branch of government. We need a Supreme Court of Technology. (Think Ph.D. instead of J.D.)

Technology is the underpinning of a sustainable economy, an economy where citizens are well-educated, healthy, and happy, and where infrastructure is safe and supports the citizens’ needs. For countries that have it, technology generates the wealth to pay for education, healthcare, and bridges. Back then it was laws; today it’s technology.

The Founding Fathers knew interpretation of laws demanded consistency, consistency that transcended the election cycle, and, with its lifetime appointment, the Supreme Court was the mechanism. And it’s the same with technology: technology demands consistency of direction and consistency of purpose, and for that reason I propose a Supreme Court of Technology.

The Chief Justice of Technology and her Associate Justices set the long term technology policy for the country. They can be derided for its long time horizon, but they cannot be ousted for making the right decisions or their consistency of purpose. The Justices decide how to best spend their annual budget, which is substantial and adjusts with inflation and population. Since they are appointed for life, the Justices tell Congress how it goes with technology (and to stop with all this gridlock gamesmanship) and ask the President for her plan to implement the country’s technology policy. (Technology transcends political parties and election cycles.)

With the Supreme Court of Technology appointed and their first technology plan in place (think environment and energy), the country is on track to generate wealth sufficient to build the best educational system in the world (think creativity, art, science, math, and problem solving) to fuel the next generation of technology leadership.

Make your green programs actionable

There’s a big push to be green. Though we want to be green, we’re not sure how to get there. We’ve got high-level metrics, but they’re not actionable. It’s time to figure out what we can change to be green.

There’s a big push to be green. Though we want to be green, we’re not sure how to get there. We’ve got high-level metrics, but they’re not actionable. It’s time to figure out what we can change to be green.

One way manufacturers can be green is to reduce their carbon footprint. That’s one level deeper than simply “being green,” but it’s not actionable either. Digging deeper, manufacturers can reduce their carbon footprint by generating less greenhouse gases, specifically carbon dioxide. Reducing carbon dioxide production is a good goal, but it’s still not actionable.

Looking deeper, carbon dioxide is the result of burning fossil fuels,

Want to be green? Look to your product.

We’re starting to come to terms with the green revolution; we’re staring to realize that green is good for our planet and even better for our business. But how do we put greenwashing behind us and truly make a difference?

We’re starting to come to terms with the green revolution; we’re staring to realize that green is good for our planet and even better for our business. But how do we put greenwashing behind us and truly make a difference?

To improve recyling, find the non-recyclable stuff in your product and design it out. Make a Pareto chart of non-recyclable stuff (by weight) by major subassembly, and focus the design effort on the biggest brown bars of the Pareto. (Consider packaging a major subassembly and give it its own bar.)

To improve carbon footprint of logistics, find the weight and volume of your product and design out the biggest and heaviest. Make a Pareto chart of weight by major subassembly, and focus the design effort on the heaviest brown bars. Make a Pareto chart of volume by major subassembly, (Make cube around the subassembly and calculate volume in mm3.) and focus the design effort on the biggest bars. (Don’t forget the packaging.)

To improve energy efficiency of your factory, find electricity consumption and design it out. Make a Pareto chart of electricity consumption by major process step then map it to the product – to the element of the product that creates the need for electricity, and focus the design effort on the biggest bars.

Going forward, here are some thoughts to help grow your business with green (and save the planet):

- It’s easier to design out brown than to design in green.

- To design out brown, you’ve got to know where it is.

- The product creates brown – look to the product to eliminate it.

Secret Sauce that Doubles Profits

Last month a group of engineers met secretly to reinvent the US economy one company at a time. Here are some of the players, maybe you’ve heard of them:

Last month a group of engineers met secretly to reinvent the US economy one company at a time. Here are some of the players, maybe you’ve heard of them:

Alcoa, BAE, Boeing, Bose, Covidien, EMC, GE Medical, GE Transportation, Grundfos, ITT, Medrad, Medtronic, Microsoft, Motorola, Pratt & Whitney, Raytheon, Samsung, Schneider Electric, Siemens, United Technologies, Westinghouse, Whirlpool.

Presenter after presenter the themes were the same: double profits, faster time to market, and better products – the triple crown of product development. Magic in a bottle, and still the best kept secret of the product development community. (No sense sharing the secret sauce when you can have it all for yourself.)

Microsoft used the secret sauce to increase profits of their hardware business by $75 million; Boeing recently elevated the secret methodology to the level of lean. Yet it’s still a secret.

What is this sauce that doubles profits without increasing sales? (That’s right, doubles.) What is this magic that decreases time to market? That reduces engineering documentation? That reduces design work itself? What is this growth strategy?

When trying to spread it on your company there are some obstacles, but the benefits should be enough to carry the day. First off, the secret sauce isn’t new, but double the profits should be enough to take a first bite. Second, its name doesn’t roll off the tongue (there’s no sizzle), but decreased time to market should justify a taste test. Last, design engineering must change its behavior (we don’t like to do that), but improved product functionality should be enough to convince engineering to swallow.

There are also two mapping problems: First, the sauce has been mapped to the wrong organization – instead of engineering it’s mapped to manufacturing, a group that, by definition, cannot do the work. (Only engineering can change the design.) Second, the sauce is mapped to the wrong word – instead of profit it’s mapped to cost. Engineering is praised for increased profits (higher function generates higher profits) and manufacturing is responsible for cost – those are the rules.

With double profits, reduced time to market, and improved product function, the name shouldn’t matter. But if you must know, its name is Design for Manufacturing and Assembly (DFMA), though I prefer to call it the secret sauce that doubles profits, reduces time to market, and improves product function.

Mike Shipulski

Mike Shipulski