Archive for the ‘Seeing Things As They Are’ Category

Which new product development project should we do first?

X: Of the pool of candidate new product development projects, which project should we do first?

X: Of the pool of candidate new product development projects, which project should we do first?

Me: Let’s do the one that makes us the most money.

X: Which project will make the most money?

Me: The one where the most customers buy the new product, pay a reasonable price, and feel good doing it.

X: And which one is that?

Me: The one that solves the most significant problem.

X: Oh, I know our company’s most significant problem. Let’s solve that one.

Me: No. Customers don’t care about our problems, they only care about their problems.

X: So, you’re saying we should solve the customers’ problem?

Me: Yes.

X: Are you sure?

Me: Yes.

X: We haven’t done that in the past. Why should we do it now?

Me: Have your previous projects generated revenue that met your expectations?

X: No, they’ve delivered less than we hoped.

Me: Well, that’s because there’s no place for hope in this game.

X: What do you mean?

Me: You can’t hope they’ll buy it. You need to know the customers’ problems and solve them.

X: Are you always like this?

Me: Only when it comes to customers and their problems.

image credit: Kyle Pearce

It’s not so easy to move manufacturing work back to the US.

I hear it’s a good idea to move manufacturing work back to the US.

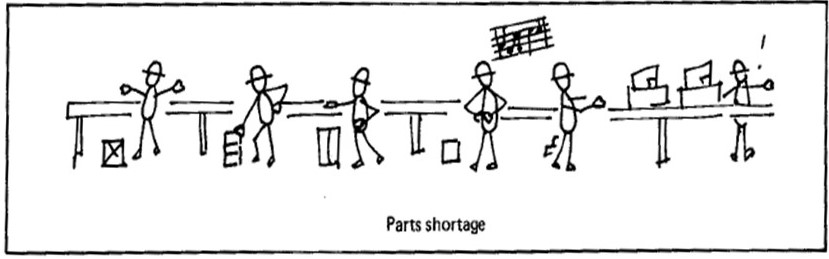

Before getting into what it would take to move manufacturing work back to the US, I think it’s important to understand why manufacturing companies moved their work out of the US. Simply put, companies moved their work out of the US because their accounting systems told them they would make more money if they made their products in countries with lower labor costs. And now that labor costs have increased in these no longer “low-cost countries”, those same accounting systems think there’s more money to be made by bringing manufacturing back to the US.

At a low level of abstraction, manufacturing, as a word, is about making discrete parts like gears, fenders, and tires using machines like gear shapers, stamping machines, and injection molding machines. The cost of manufacturing the parts is defined by the cost of the raw material, the cost of the machines, the cost of energy to power the machines, the cost of the factory, and the cost of the people to run the machines. And then there’s assembly, which, as a word, is about putting those discrete parts together to make a higher-level product. Where manufacturing makes the gears, fenders, and tires, assembly puts them together to make a car. And the cost of assembly is defined by the cost of the factory, the cost of fixtures, and the cost of the people to assemble the parts into the product. And the cost of the finished product is the sum of the cost of making the parts (manufacturing) and the cost of putting them together (assembly).

It seems pretty straightforward to make more money by moving the manufacturing of discrete parts back to the US. All that has to happen is to find some empty factory space, buy new machines, land them in the factory, hire the people to run the machines, train them, source the raw material, hire the manufacturing experts to reinvent/automate the manufacturing process to reduce cycle time and reduce labor time and then give them six months to a year to do that deep manufacturing work. That’s quite a list because there’s little factory space available that’s ready to receive machines, the machines cost money, there are few people available to do manufacturing work, the cost to train them is high (and it takes time and there are no trained trainers). But the real hurdles are the deep work required to reinvent/automate the process and the lack of manufacturing experts to do that work. The question you should ask is – Why does the manufacturing process have to be reinvented/automated?

There’s a dirty little secret baked into the accounting systems’ calculations. The cost accounting says there can be no increased profit without reducing the time to make the parts and reducing the labor needed to make them. If the work is moved from country A to country B and the costs (cycle time, labor hours, labor rate) remain constant, the profit remains constant. Simply moving from country A to country B does nothing. Without the deep manufacturing work, profits don’t increase. And if your country doesn’t have the people with the right expertise, that deep manufacturing work cannot happen.

And the picture is similar for moving assembly work back to the US. All that has to happen is to find empty factory space, hire and train people to do the assembly work, reroute the supply chains to the new factory, redesign the product so it can be assembled with an automated assembly line, hire/train the people to redesign the product so it can be assembled in an automated way, design the new automated assembly process, build it, test it, hire/train the automated assembly experts to do that work, hire the people to support and run the automated assembly line, and pay for the multi-million-dollar automated assembly line. And the problems are similar. There’s not a lot of world-class factory space, there are few people available to run the automated assembly line, and the cost of the automated assembly line is significant. But the real problems are the lack of experts to redesign the product for automated assembly and the lack of expertise to design, build, and validate the assembly line. And here are the questions you should ask – Why do we need to automate the assembly process and why does the product have to be redesigned to do that?

It’s that dirty little secret rearing its ugly head again. The cost accounting says there can be no increased profit without reducing the labor to assemble the parts. make them. If the work is moved from country A to country B and the assembly costs (labor hours, labor rate) remain constant, the profit remains constant. Simply moving from country A to country B does nothing. Without deep design work (design for automated assembly) and ultra-deep automated assembly work, profits don’t increase. And if your country doesn’t have the people with the right expertise, that deep design and automated assembly work cannot happen.

If your company doesn’t have the time, money, and capability to reinvent/automate manufacturing processes, it’s a bad idea to move manufacturing work back to the US. It simply won’t work. Instead, find experts who can help you develop/secure the capability to reinvent/automate manufacturing processes to reduce the cost of manufacturing.

If your company doesn’t have the time, money, and capability to design products for automated assembly and to design, build, and validated automated assembly systems, it’s a bad idea to move assembly work back to the US. It, too, simply won’t work. Instead, partner with experts who know how to do that work so you can reduce the cost of assembly.

What would you do differently if you believed in yourself more?

Belief in yourself manifests in your actions. What do your actions say about your belief in yourself?

Belief in yourself doesn’t mean everything will work out perfectly. It means that you’ll be okay regardless of how things turn out.

When you see someone that doesn’t believe in themselves, how do you feel? And what do you do?

And when that someone is you, how do you feel? And what do you do?

When someone believes in you more than you do, do you believe them?

You reach a critical threshold when your belief in yourself can withstand others’ judgment of you.

When you believe in yourself, you don’t define yourself by what others think of you.

When you love yourself more, you believe in yourself more.

If you had a stronger belief in yourself, what would you do differently?

Try this. Make a list of three things you’d do differently if you had a stronger belief in yourself. Then, find one of those special people that believe in you and show them your list. And whatever they say about your list, believe them.

Image credit — ajari

The Power of Leaving a Problem Unsolved

Nothing changes unless there’s a problem.

Nothing changes unless there’s a problem.

In fact, without a problem, there can be no solution.

One of the devious ways to solve your problem is to create conditions for others to think it’s their problem.

Shame on you if you try to get me to solve your problem.

And shame on me if I try to solve your problem.

The best way for the problem to find its rightful owner is to leave the problem unsolved.

But leaving the problem unsolved also increases the pressure on all the innocent non-owners that work near the problem.

Leaving the problem unsolved is like a game of chicken, where the person who flinches first loses.

No one can give you their problem without your consent, but that doesn’t mean they won’t try.

So, when someone tries to give you their problem, put your hands in your pockets.

Leaving the problem unsolved isn’t a sign of non-caring, it’s a sign of higher-level caring.

Leaving the problem unsolved is the only way to pressure the company into the higher-level (and unpleasant) organizational learning of who is not solving their own problems.

“Prepare for Squirting” by Wootang01 is licensed under CC BY-ND 2.0.

Rediscovering The Power of Getting Together In-Person

When you spend time with a group in person, you get to know them in ways that can’t be known if you spend time with them using electronic means. When meeting in person, you can tell when someone says something that’s difficult for them. And you can also tell when that difficulty is fake. When using screens, those two situations look the same, but, in person, you know they are different. There’s no way to quantify the value of that type of discernment, but the value borders on pricelessness.

When you spend time with a group in person, you get to know them in ways that can’t be known if you spend time with them using electronic means. When meeting in person, you can tell when someone says something that’s difficult for them. And you can also tell when that difficulty is fake. When using screens, those two situations look the same, but, in person, you know they are different. There’s no way to quantify the value of that type of discernment, but the value borders on pricelessness.

When people know you see them as they really are, they know you care. And they like that because they know your discernment requires significant effort. Sure, at first, they may be uncomfortable because you can see them as they are, but, over time, they learn that your ability to see them as they are is a sign of their importance. And there’s no need to call this out explicitly because all that learning comes as a natural byproduct of meeting in person.

And the game changes when people know you see them (and accept them) for who they are. The breadth of topics that can be discussed becomes almost limitless. Personal stories flow; family experiences bubble to the surface; misunderstandings are discussed openly; vulnerable thoughts and feelings are safely expressed; and trust deepens.

I think we’ve forgotten the power of working together in person, but it only takes three days of in-person project work to help us remember. If you have an important project deliverable, I suggest you organize a three-day, in-person event where a small group gets together to work on the deliverable. Create a formal agenda where it’s 50% work and 50% not work. (I’ve found that the 50% not work is the most valuable and productive.) Make it focused and make it personal. Cook food for the group. Go off-site to a museum. Go for a hike. And work hard. But, most importantly, spend time together.

Things will be different after the three-day event. Sure, you’ll make progress on your project deliverable, but, more importantly, you’ll create the conditions for the group to do amazing work over the next five years.

“Elephants Amboseli” by blieusong is licensed under CC BY-SA 2.0.

It’s good to have experience, until the fundamentals change.

We use our previous experiences as context for decisions we make in the present. When we have a bad experience, the experience-context pair gets stored away in our memory so that we can avoid a similar bad outcome when a similar context arises. And when we have a good experience, or we’re successful, that memory-context pair gets stored away for future reuse. This reuse approach saves time and energy and, most of the time keeps us safe. It’s nature’s way of helping us do more of what works and less of what doesn’t.

We use our previous experiences as context for decisions we make in the present. When we have a bad experience, the experience-context pair gets stored away in our memory so that we can avoid a similar bad outcome when a similar context arises. And when we have a good experience, or we’re successful, that memory-context pair gets stored away for future reuse. This reuse approach saves time and energy and, most of the time keeps us safe. It’s nature’s way of helping us do more of what works and less of what doesn’t.

The system works well when we correctly match the historical context with today’s context and the system’s fundamentals remain unchanged. There are two potential failure modes here. The first is when we mistakenly map the context of today’s situation with a memory-context pair that does not apply. With this, we misapply our experience-based knowledge in a context that demands different knowledge and different decisions. The second (and more dangerous) failure mode is when we correctly identify the match between past and current contexts but the rules that underpin the context have changed. Here, we feel good that we know how things will turn out, and, at the same time, we’re oblivious to the reality that our experience-based knowledge is out of date.

“If a cat sits on a hot stove, that cat won’t sit on a hot stove again. That cat won’t sit on a cold stove either. That cat just don’t like stoves.” Mark Twain

If you tried something ten years ago and it failed, it’s possible that the underpinning technology has changed and it’s time to give it another try.

If you’ve been successful doing the same thing over the last ten years, it’s possible that the underpinning business model has changed and it’s time to give a different one a try.

“Hissing cat” by Consumerist Dot Com is licensed under CC BY 2.0.

The Ins and Outs of Things

When things are overwhelming to you but not to others, it’s okay to feel overwhelmed for a while.

When things are overwhelming to you but not to others, it’s okay to feel overwhelmed for a while.

When the seas are rough, you may think you are alone, but others may see it differently.

What’s worthy of your attention is defined by you, though some make it easy for you to think otherwise.

When you disagree with someone’s idea, that says nothing about them.

Judging someone from the outside is unfair, and it’s the same with judging yourself from the inside.

When everyone around you sees you differently than you see yourself, it’s worth looking critically at what you see that they don’t and what they see that you don’t.

You aren’t your thoughts and feelings, but it can feel like it in the heat of the moment.

Self-judgment is the strongest flavor of judgment.

“Object from the exhibition We call them Vikings produced by The Swedish History Museum” by The Swedish History Museum, Stockholm is licensed under CC BY 2.0.

The first step is to understand the system as it is.

If there’s a recurring problem, take the time to make sure the system hasn’t changed since last time and make sure the context and environment are still the same. If everything is the same, and there are no people involved in the system, it’s a problem that resides in the clear domain. Here’s a link from Dave Snowden who talks about the various domains. In this video, Dave calls this domain the “simple” domain. Solve it like you did last time.

If there’s a recurring problem, take the time to make sure the system hasn’t changed since last time and make sure the context and environment are still the same. If everything is the same, and there are no people involved in the system, it’s a problem that resides in the clear domain. Here’s a link from Dave Snowden who talks about the various domains. In this video, Dave calls this domain the “simple” domain. Solve it like you did last time.

If there’s a new problem, take the time to understand the elements of the system that surround the problem. Define the elements and define how they interact, and define how they set the context and constraints for the problem. And then, define the problem itself. Define when it happens, what happens just before, and what happens after. If there are no people involved, if the solution is not immediately evident, if it’s a purely mechanical, electromechanical, chemical, thermal, software, or hardware, it’s a problem in the complicated domain (see Dave’s video above) and you’ll be able to solve it with the right experts and enough time.

If you want to know the next evolution of the system, how it will develop and evolve, the situation is more speculative and there’s no singular answer. Still, the first step is the same – take the time to understand the elements of the system and how they interact. Then, look back in time and learn the previous embodiments of the system and define its trajectory – how it evolved into its current state. If there has been consistent improvement along a singular line of goodness, it’s likely the system will want to continue to evolve in that direction. If the improvement has flattened, it’s likely the system will try to evolve along a different line of evolution.

I won’t go into the specifics of lines of evolution of technological systems, as it’s a big topic. But if you want to know more, here’s a nice description of evolution along the line of adaptability by my teacher, Victor Fey – The best products know how to adapt.

If there are people involved with the system, it’s a complex system (see Dave’s video). (There are complex systems that don’t involve people, but I find this a good way to talk about complex systems.) The first step is to define the system as it is, but because the interactions among the elements are not predictable, your only hope is to probe, sense, and respond by doing more of what works and less of what doesn’t. Thanks to Dave Snowden for that language.

The first step is always to understand the system as it is.

“Space – Antennae Galaxies” by Trodel is licensed under CC BY-SA 2.0.

Free Resources

Since resources are expensive, it can be helpful to see the environment around your product as a source of inexpensive resources that can be modified to perform useful functions. Here are some examples.

Since resources are expensive, it can be helpful to see the environment around your product as a source of inexpensive resources that can be modified to perform useful functions. Here are some examples.

Gravity is a force you can use to do your bidding. Since gravity is always oriented toward the center of the earth, if you change the orientation of an object, you change the direction gravity exerts itself relative to the object. If you flip the object upside down, gravity will push instead of pull.

And it’s the same for buoyancy but in reverse. If you submerge an object of interest in water and add air (bubbles) from below, the bubbles will rise and push in areas where the bubbles collect. If you flip over the object, the bubbles will collect in different areas and push in the opposite direction relative to the object.

And if you have water and bubbles, you have a delivery system. Add a special substance to the air which will collect at the interface between the water and air and the bubbles will deliver it northward.

If you have motion, you also have wind resistance or drag force (but not in deep space). To create more force, increase speed or increase the area that interacts with the moving air. To change the direction of the force relative to the object, change the orientation of the object relative to the direction of motion.

If you have water, you can also have ice. If you need a solid substance look to the water. Flow water over the surface of interest and pull out heat (cool) where you want the ice to form. With this method, you can create a protective coating that can regrow as it gets worn off.

If you have water, you can make ice to create force. Drill a blind hole in a piece of a brittle material (granite), fill the hole with water, and freeze the water by cooling the granite (or leave it outside in the winter). When the water freezes it will expand, push on the granite and break it.

These are some contrived examples, but I hope they help you see a whole new set of free resources you can use to make your magic.

Thank you, VF.

Image credit – audi_insperation

Is it time to break the logjam?

Clearing a logjam is not about increasing the force of the water. It’s about moving one log out of the way, watching what happens, and choosing the next log to move.

Crossing a raging river is not about pushing against the current. It’s about seeing what’s missing and using logs to build a raft.

Trekking across the tundra after crossing the raging river is not about holding onto the logs that helped you cross. It’s about seeing what’s not needed and leaving the raft by the river.

The trick is to know when to move the logs, when to use them to build a raft, and when to leave them behind.

Image credit: “Log Jam Mural _ Stillwater MN” by Kathleen Tyler Conklin is licensed under CC BY 2.0.

What you do next is up to you.

If you don’t know why you’re doing what you’re doing, you can try to remember why you started the whole thing or you can do something else. Either can remedy things, but how do you choose between them? If you’ve forgotten your “why”, maybe it’s worth forgetting or maybe something else temporarily came up that pushed your still-important why underground for a short time. If it’s worth forgetting, maybe it’s time for something else. And if it’s worth remembering, maybe it’s time to double down. Only you can choose.

If you don’t know why you’re doing what you’re doing, you can try to remember why you started the whole thing or you can do something else. Either can remedy things, but how do you choose between them? If you’ve forgotten your “why”, maybe it’s worth forgetting or maybe something else temporarily came up that pushed your still-important why underground for a short time. If it’s worth forgetting, maybe it’s time for something else. And if it’s worth remembering, maybe it’s time to double down. Only you can choose.

If you still remember why you’re doing what you’re doing, you can ask yourself if your why is still worth its salt or if something changed, either inside you or in your circumstances, that has twisted your why to something beyond salvage. If your why is still as salty as ever, maybe it’s right to stay the course. But if it’s still as salty as ever but you now think it’s distasteful, maybe it’s time for a change.

When you do what you did last time, are you more efficient or more dissatisfied, or both? And if you imagine yourself doing it again, do you look forward to more efficiency or predict more dissatisfaction? These questions can help you decide whether to keep things as they are or change them.

What have you learned over the last year? Whether your list is long or if it’s short, it’s a good barometer to inform your next chapter.

What new skills have you mastered over the last year? Is the list long or short? If you don’t want to grow your mastery, keep things as they are.

Do the people you work with inspire you or bring you down? Are you energized or depleted by them? If you’re into depletion, there’s no need to change anything.

Do you have more autonomy than last year? And how do you feel about that? Let your answers guide your future.

What is the purpose behind what you do? Is it aligned with your internal compass? These two questions can bring clarity.

You’re the only one who can ask yourself these questions; you’re the only one who can decide if you like the answers; and you’re the only one who is responsible for what you do next. What you do next is up to you.

“Fork in the road” by Kai Hendry is licensed under CC BY 2.0.

Mike Shipulski

Mike Shipulski