Archive for the ‘How To’ Category

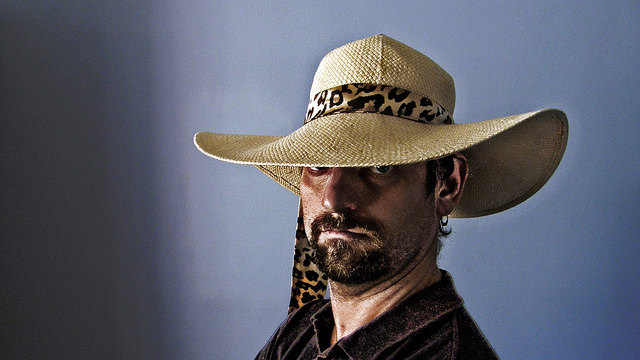

The Chief Do-the-Right-Thing Officer – a new role to protect your brand.

Our unhealthy fascination with ever-increasing shareholder value has officially gone too far. In some companies dishonesty is now more culturally acceptable than missing the numbers. (Unless, of course, you get caught. Then, it’s time for apologies.) The sacrosanct mission statement can’t save us. Even the most noble can be stomped dead by the dirty boots of profitability.

Our unhealthy fascination with ever-increasing shareholder value has officially gone too far. In some companies dishonesty is now more culturally acceptable than missing the numbers. (Unless, of course, you get caught. Then, it’s time for apologies.) The sacrosanct mission statement can’t save us. Even the most noble can be stomped dead by the dirty boots of profitability.

Though, legally, companies can self-regulate, practically, they cannot. There’s nothing to balance the one-sided, hedonistic pursuit of profitability. What’s needed is a counterbalancing mechanism of equal and opposite force. What’s needed is a new role that is missing from today’s org chart and does not have a name.

Ombudsman isn’t the right word, but part of it is right – the part that investigates. But the tense is wrong – the ombudsman has after-the-fact responsibility. The ombudsman gets to work after the bad deed is done. And another weakness – ombudsman don’t have equal-and-opposite power of the C-suite profitability monsters. But most important, and what can be built on, is the independent nature of the ombudsman.

Maybe it’s a proactive ombudsman with authority on par with the Board of Directors. And maybe their independence should be similar to a Supreme Court justice. But that’s not enough. This role requires hulk-like strength to smash through the organizational obfuscation fueled by incentive compensation and x-ray vision to see through the magical cloaking power of financial shenanigans. But there’s more. The role requires a deep understanding of complex adaptive systems (people systems), technology, patents and regulatory compliance; the nose of an experienced bloodhound to sniff out the foul; and the jaws of a pit bull that clamp down and don’t let go.

Ombudsman is more wrong than right. I think liability is better. Liability, as a word, has teeth. It sounds like it could jeopardize profitability, which gives it importance. And everyone knows liability is supposed to be avoided, so they’d expect the work to be proactive. And since liability can mean just about anything, it could provide the much needed latitude to follow the scent wherever it takes. Chief Liability Officer (CLO) has a nice ring to it.

[The Chief Do-The-Right-Thing Officer is probably the best name, but its acronym is too long.]

But the Chief Liability Officer (CLO) must be different than the Chief Innovation Officer (CIO), who has all the responsibility to do innovation with none of the authority to get it done. The CLO must have a gavel as loud as the Chief Justice’s, but the CLO does not wear the glasses of a lawyer. The CLO wears the saffron robes of morality and ethics.

Is Chief Liability Officer the right name? I don’t know. Does the CLO report to the CEO or the Board of Directors? Don’t know. How does the CLO become a natural part of how we do business? I don’t know that either.

But what I do know, it’s time to have those discussions.

Image credit – Dietmar Temps

Geometric Success Through Mentorship

Business processes and operating plans don’t get things done. People do. And the true blocker of progress is not bureaucracy; it’s the lack of clarity of people. And that’s why mentorship is so important.

Business processes and operating plans don’t get things done. People do. And the true blocker of progress is not bureaucracy; it’s the lack of clarity of people. And that’s why mentorship is so important.

My definition of mentorship is: work that provides knowledge, support and advocacy necessary for new people to get things done. New can be new to company, new to role, or new to new environments or circumstances.

Mentorship is about helping new people recognize and understand unwritten rules on how things are done; helping them see the invisible power dynamics that generate the invisible forcing function that makes things happen; and supporting them as they navigate the organizational riptide.

The first job of a mentor is to commit to spending time with a worthy mentee. Check-the-box mentorship (mentorship for compliance) does not take a lot of time. (Usually several meetings will do.) But mentorship done well, mentorship worthy of the mentee, takes time and emotional investment.

Mentorship starts with a single page definition of the projects the mentee must get done. It’s a simple spreadsheet where each project has its own row with multiple columns for the projects that define: what must get done by the end of the year, and how to know it was done; the major milestones (and dates) along the way; what was done last month; what will be done this month. After all the projects are listed in order of importance, the number of projects is reduced from 10-20 down to 3-4. The idea is to list on the front of the page only the projects that can be accomplished by a mere mortal. The remaining 16-17 are moved to the back, never to be discussed again. (It’s still one page if you use the back.)

[Note: The mentee’s leader will be happy you helped reduce the workload down to a reasonable set of projects. They knew there were too many projects, but their boss wanted them to sign up for too much to ensure there was no chance of success and no time to think.]

Once the year-end definition of success is formalized for each project, this month’s tasks are defined. Using your knowledge of organizational dynamics and how things actually get done, you tell them what to do and how to do it. For the next four weekly meetings you ask them what they and help them get the tasks done. You don’t do the tasks for them, you tell them how to do it and how to work with. Over the next months, telling morphs to suggesting.

The learning comes when your suggested approach differs from their logical, straightforward approach. You explain the history, explain the official process is outdated and no one does it that way, suggest they talk to the little-known subject matter expert who has done similar work and introduce them to the deep-in-the-org-chart stalwart who can allocate resources to support the work.

Week-by-week and month-by-month, the project work gets done and the mentee learns how to get it done. The process continues for at least one year. If you are not willing to meet 40-50 times over the course of a year, you aren’t serious about mentorship. Think that’s too much? It isn’t. That’s what it takes. Still think that’s too much? If you meet for 30 minutes a week, that’s only 20-25 hours per year. At the end of a year, 3-4 projects will be completed successfully and a new person will know how to do 3-4 more next year, and the year after that. Then, because they know the value of mentorship, they become a mentor and help a new person get 3-4 projects done. That’s a lot of projects. Done right, success through mentorship is geometric.

Companies are successful when they complete their projects. And the knowledge needed to complete the projects is not captured in the flowcharts of the official business processes – it’s captured in the hearts and minds of the people.

New people don’t know how things get done, but they need to. And mentorship is the best way to teach them. It’s impossible to calculate the return on investment (ROI) for mentorship. You either believe in mentorship or you don’t. And I believe in it.

My mentorship work is my most meaningful work, and it has little to do with the remarkable business results. The personal relationships I have developed through my mentorship work are some of the most rewarding of my life.

I urge you, for your own well-being, to give mentorship a try.

Image credit — Bryan Jones

A most powerful practice – Try It.

The first question is usually – What’s the best practice? And the second question is – Why aren’t you using it? In the done-it-before domain this makes sense. Best practices are best when inputs are tightly controlled, process steps are narrowly defined, and the desired output is known and can be formally defined.

The first question is usually – What’s the best practice? And the second question is – Why aren’t you using it? In the done-it-before domain this makes sense. Best practices are best when inputs are tightly controlled, process steps are narrowly defined, and the desired output is known and can be formally defined.

Industry loves best practice because they are so productive. Like the printing press, best practices are highly effective when it’s time to print the same pages over and over. It worked here, so do it there. And there. And there. Use the same typeface and crank it out – page by page. It’s like printing money.

Best practices are best utilized in the manufacturing domain, until they’re not. Which best practice should be used? Can it be used as-is, or must it change? And, if a best practice is changed, which version is best? Even in the tightly controlled domain of manufacturing, it’s tricky to effectively use best practices. (Maybe what’s needed is a best practice for using best practices.)

Best practices can be good when there’s strong commonality with previous work, but when the work is purposefully different (think creativity and innovation), all bets are off. But that doesn’t stop the powerful pull of productivity from jamming round best practices into square holes. In the domain of different, everything’s different – the line of customer goodness, the underpinning technology and the processes to make it, sell it, and service it. By definition, the shape of a best practice does not fit work that has yet to be done for the first time.

What’s needed is a flexible practice that can handle the variability, volatility, and uncertainty of creativity/innovation. My favorite is called – Try It. It’s a simple process (just one step), but it’s a good one. The hard part is deciding what to try. Here are some ways to decide.

No-to-yes. Define the range of inputs for the existing products and try something outside those limits.

Less-with-far-less. Reduce the performance (yes, less performance) of the very thing that makes your product successful and try adolescent technologies with a radically lower cost structures. When successful, sell to new customers.

Lines of customer goodness. Define the primary line of customer goodness of your most successful product and try things that advance different lines. When you succeed, change all your marketing documents and sales tools, reeducate your sales force, and sell the new value to new customers.

Compete with no one. Define a fundamental constraint that blocks all products in your industry, try new ideas that compromise everything sacred to free up novel design space and break the constraint. Then, sell new products into the new market you just created.

IBE (Innovation Burst Event). Everything starts with a business objective.

There is no best way to implement the Try It process, other than, of course, to try it.

Image credit — Alland Dharmawan.

Innovation isn’t a thing in itself.

Innovation isn’t a thing in itself, and it’s not something to bolster for the sake of bolstering.

Innovation isn’t a thing in itself, and it’s not something to bolster for the sake of bolstering.

Innovation creates things (products, services, business models) that are novel, useful and successful. It’s important to know which flavor to go after, but before that it’s imperative to formalize the business objective. Like lean or Six Sigma, innovation is a business methodology whose sole intention is to deliver on the business objective. The business objective is usually a revenue or profit goal, and success is defined by meeting the objective. Successful is all about meeting the business objective and successful is all about execution.

There are a lot of things that must come together for an innovation to be successful. For an innovative product here are the questions to answer: Can you make it, certify it, market it, sell it, distribute it, service it, reclaim it? As it happens, these are the same questions to answer for any new product. In that way, innovative products are not different. But because innovation starts with novel, with innovative products the answers can be different. For an innovative product there are more “no’s” and for each no there’s a reason that starts with a C: constraint, capacity, capability, competitor, cooperation, capital. And the business objective cannot be achieved with closing the gaps.

After successful, there’s useful. Like any work based on a solid marketing methodology, innovation must deliver usefulness to the customer. Innovation or not, strong marketing is strong marketing and strong marketing defines who the customer is, how they’ll use the new service, and how they’ll benefit – the valuable customer outcome (VCO.) But with an innovative service it’s more difficult to know who the customer is, how they’ll use the service and if they’ll pay for it. (That’s the price of novelty.) But in most other ways, an innovative service is no different than any other service. Both are successful because they deliver usefulness customers, those customers pay money for the usefulness and the money surpasses the business objective.

Innovation is different because of novelty, but only in degree. Continuous improvement projects have novelty. Usually, it’s many small changes consistently applied that add up to meaningful results, for example waste reduction, improved throughput and product quality. These projects have novelty, but the novelty is the sum of small steps, all of which stay close to known territory.

The next rung on the novelty ladder is discontinuous improvement which creates a large step change in goodness provided to the customer. (Think 3X improvement.) The high degree of novelty creates broader uncertainty. Will the customer be able to realize the goodness? Will the novelty be appealing to a set of yet-to-be-discovered customers? Will they pay for it? It is worth doing all that execution work? Will it cannibalize other products? The novelty is a strong divergence from the familiar and with it comes the upside of new customer goodness and the downside of the uncertainty.

The highest form of novelty is no-to-yes. No other product on the planet could do it before, but the new innovative one can. It has the potential to create new markets, but also has the potential to obsolete the business model. The sales team doesn’t know how to sell it, the marketers don’t know how to market it and the factory doesn’t know how to make it. There new technology is not as robust as it should be and the cost structure may never become viable. There’s no way to predict how competitors will respond, there’s no telling if it will pass the regulatory requirements. And to top it off, no one is sure who the customer is or if anyone will it. But, if it all comes together, this innovation will be a game-changer.

Innovation is the same as all the other work, except there’s more novelty. And with that novelty comes more upside and more uncertainty. With novelty, too much of a good thing isn’t wonderful. Sufficient novelty must be ingested to meet the business objective, and a bit more for the long term to stay out in front.

Be clear about business objectives, deliver usefulness to customers and use novelty to make it happen. And call it whatever you want.

Image credit – Agustin Rafael Reyes

Serious Business

If you’re serious about your work, you’re too serious. We’re all too bound up in this life-or-death, gotta-meet-the-deadline nonsense that does nothing but get in the way.

If you’re serious about your work, you’re too serious. We’re all too bound up in this life-or-death, gotta-meet-the-deadline nonsense that does nothing but get in the way.

If you’re into following recipes, I guess it’s okay to be held accountable to measuring the ingredients accurately and mixing the cake batter with 110% effort. When your business is serious about making more cakes than anyone else on the planet, it’s fine to take that seriously. But if you’re into making recipes, serious doesn’t cut it. Coming up with new recipes demands the freedom of putting together spices that have never been combined. And if you’re too serious, you’ll never try that magical combination that no one else dared.

Serious is far different than fully committed and “all in.” With fully committed, you bring everything you have, but you don’t limit yourself by being too serious. When people are too serious they pucker up and do what they did last time. With “all in” it’s just that – you put all your emotional chips on the line and you tell the dealer to “hit.” If the cards turn in your favor you cash in in a big way. If you bust, you go home, rejuvenate and come back in the morning with that same “all in” vigor you had yesterday and just as many chips. When you’re too serious, you bet one chip at a time. You don’t bet many chips, so you don’t lose many. But you win fewer.

The opposite of serious is not reckless. The opposite of serious is energetic, extravagant, encouraging, flexible, supportive and generous. A culture of accountability is serious. A culture of creativity is not.

I do not advocate behavior that is frivolous. That’s bad business. I do advocate behavior that is daring. That’s good business. Serious connotes measurable and quantifiable, and that’s why big business and best practices like serious. But measurable and quantifiable aren’t things in themselves. If they bring goodness with them, okay. But there’s a strong undercurrent of measurable for measurable’s sake. It’s like we’re not sure what to do, so we measure the heck out of everything. Daring, on the other hand, requires trust is unmeasurable. Never in the history of Six Sigma has there been a project done on daring and never has one of its control strategies relied on trust. That’s because Six Sigma is serious business. Serious connotes stifling, limiting and non-trusting, and that’s just what we don’t need.

Let’s face it, Six Sigma and lean are out of gas. So is tightening-the-screws management. The low hanging fruit has been picked and Human Resources has outed all the mis-fits and malcontents. There’s nothing left to cut and no outliers to eliminate. It’s time to put serious back in its box.

I don’t know what they teach in MBA programs, but I hope it’s trust. And I don’t know if there’s anything we can do with all our all-too-serious managers, but I hope we put them on a program to eliminate their strengths and build on their weaknesses. And I hope we rehire the outliers we fired because they scared all the serious people with their energy, passion and heretical ideas.

When you’re doing the same thing every day, serious has a place. When you’re trying to create the future, it doesn’t. To create the future you’ve got to hire heretics and trust them. Yes, it’s a scary proposition to try to create the future on the backs of rabble-rousers and rebels. But it’s far scarier to try to create it with the leagues of all-too-serious managers that are running your business today.

Image credit — Alan

Hands-On or Hands-Off?

Hands-on versus hands-off – as a leader it’s a fundamental choice. And for me the single most important guiding principle is – do what it takes to maintain or strengthen the team’s personal ownership of the work.

Hands-on versus hands-off – as a leader it’s a fundamental choice. And for me the single most important guiding principle is – do what it takes to maintain or strengthen the team’s personal ownership of the work.

If things are going well, keep your hands off. This reinforces the team’s ownership and your trust in them. But it’s not hands-off in and ignore them sense; it’s hands-off in a don’t tell them what to do sense. Walk around, touch base and check in to show interest in the work and avoid interrogation-based methods that undermine your confidence in them. This is not to say a hands-off leader only superficially knows what’s going on, it should only look like the leader has a superficial understanding.

The hands-off approach requires a deep understanding of the work and the people doing it. The hands-off leader must make the time to know the GPS coordinates of the project and then do reconnaissance work to identify the positions of the quagmires and quicksand that lay ahead. The hands-off leader waits patiently just in front of the obstacles and makes no course correction if the team can successfully navigate the gauntlet. But when the team is about to sink to their waists, leader gently nudges so they skirt the dangerous territory.

Unless, of course, the team needs some learning. And in that case, the leader lets the team march it’s project into the mud. If they need just a bit of learning the leader lets them get a little muddy; and if the team needs deep learning, the leader lets them sink to their necks. Either way, the leader is waiting under cover as they approach the impending snafu and is right beside them to pull them out. But to the team, the hands-off leader is not out in front scouting the new territory. To them, the hands-off leader doesn’t pay all that much attention. To the team, it’s just a coincidence the leader happens to attend the project meeting at a pivotal time and they don’t even recognize when the leader subtly plants the idea that lets the team pull themselves out of the mud.

If after three or four near-drowning incidents the team does not learn or change it’s behavior, it’s time for the hands-off approach to look and feel more hands-on. The leader calls a special meeting where the team presents the status of the project and grounds the project in the now. Then, with everyone on the same page the leader facilitates a process where the next bit of work is defined in excruciating detail. What is the next learning objective? What is the test plan? What will be measured? How will it be measured? How will the data be presented? If the tests go as planned, what will you know? What won’t you know? How will you use the knowledge to inform the next experiments? When will we get together to review the test results and your go-forward recommendations?

By intent, this tightening down does not go unnoticed. The next bit of work is well defined and everyone is clear how and when the work will be completed and when the team will report back with the results. The leader reverts back to hands-off until the band gets back together to review the results where it’s back to hands-on. It’s the leader’s judgement on how many rounds of hands-on roulette the team needs, but the fun continues until the team’s behavior changes or the project ends in success.

For me, leadership is always hands-on, but it’s hands-on that looks like hands-off. This way the team gets the right guidance and maintains ownership. And as long as things are going well this is a good way to go. But sometimes the team needs to know you are right there in the trenches with them, and then it’s time for hands-on to look like hands-on. Either way, its vital the team knows they own the project.

There are no schools that teach this. The only way to learn is to jump in with both feet and take an active role in the most important projects.

Image credit – Kerri Lee Smith

Don’t worry about the words, worry about the work.

Doing anything for the first time is difficult. It goes with the territory. Instead of seeing the associated anxiety as unwanted and unpleasant, maybe you can use it as an indicator of importance. In that way, if you don’t feel anxious you know you’re doing what you’ve done before.

Doing anything for the first time is difficult. It goes with the territory. Instead of seeing the associated anxiety as unwanted and unpleasant, maybe you can use it as an indicator of importance. In that way, if you don’t feel anxious you know you’re doing what you’ve done before.

Innovation, as a word, has been over used (and misused). Some have used the word to repackage the same old thing and make it fresh again, but more commonly people doing good work attach the word innovation to their work when it’s not. Just because you improved something doesn’t mean it’s innovation. This is the confusion made by the lean and Six Sigma movements – continuous improvement is not innovation. The trouble with saying that out loud is people feel the distinction diminishes the importance of continuous improvement. Continuous improvement is no less important than innovation, and no more. You need them both – like shoes and socks. But problems arise when continuous improvement is done in the name of innovation and innovation is done at the expense of continuous improvement – in both cases it’s shoes, no socks.

Coming up with an acid test for innovation is challenging. Innovation is a know-it-when-you-see-it thing that’s difficult to describe in clear language. It’s situational, contextual and there’s no prescription. [One big failure mode with innovation is copying someone else’s best practice. With innovation, cutting and pasting one company’s recipe into another company’s context does not work.] But prescriptions and recipes aside, it can be important to know when it’s innovation and when it isn’t.

If the work creates the foundation that secures your company’s growth goals, don’t worry about what to call it, just do it. If that work doesn’t require something radically new and different, all-the-better. But you likely set growth goals that were achievable regardless of the work you did. But still, there’s no need to get hung up on the label you attach to the work. If the work helps you sell to customers you could not sell to before, call it what you will, but do more of it. If the work creates a whole new market, what you call it does not matter. Just hurry up and do it again.

If your CEO is worried about the long term survivability of your company, don’t fuss over labelling your work with the right word, do something different. If you have to lower your price to compete, don’t assign another name to the work, do different work. If your new product is the same as your old product, don’t argue if it’s the result of continuous improvement or discontinuous improvement. Just do something different next time.

Labelling your work with the right word is not the most important thing. It’s far more important to ask yourself – Five years from now, if the company is offering a similar product to a similar set of customers, what will it be like to work at the company? Said another way, arguing about who is doing innovation and who is not gets in the way of doing the work needed to keep the company solvent.

If the work scares you, that’s a good indication it’s meaningful. And meaningful is good. If it scares you because it may not work, you’re definitely trying something new. And that’s good. But it’s even better if the work scares you because it just might come to be. If that’s the case, your body recognizes the work could dismantle a foundational element of your business – it either invalidates your business model or displaces a fundamental technology. Regardless of the specifics, anxiety is a good surrogate for importance.

In some cases, it can be important what you call the work. But far more important than getting the name right is doing the right work. If you want to argue about something, argue if the work is meaningful. And once a decision is reached, act accordingly. And if you want to have a debate, debate the importance of the work, then do the important work as fast as you can.

Do the important work at the expense of arguing about the words.

To make a difference, add energy.

If you want to make a difference, you’ve got to add energy. And the more you can add the bigger difference you can make.

If you want to make a difference, you’ve got to add energy. And the more you can add the bigger difference you can make.

Doing new is difficult and demands (and deserves) all the energy you can muster. Often it feels you’re the only one pushing in the right direction while everyone else is vehemently pushing the other way. But stay true and stand tall. This is not an indication things are going badly, this is a sign you’re doing meaningful work. It’s supposed to feel that way. If you’re exhausted, frustrated and sometimes a bit angry, you’re doing it right. If you have a healthy disrespect for the status quo, it’s supposed to feel that way.

Meaningful work has a long time constant and you’ve got to run these meaningful projects like marathons, uphill marathons. Every day you put in your 26 miles at a sustainable pace – no slower, but no faster. This is long, difficult work that doesn’t run by itself, you’ve got to push it like a sled. Every day you’ve got to push. To push every day like this takes a lot of physical strength, but it takes even more mental strength. You’ve got to stay focused on the critical path and push that sled every day. And you need to preserve enough mental energy to effectively ignore the non-critical path sleds. You’ve got to be able to decide which tasks you must get your whole body behind and which tasks you must discount. And you’ve got to preserve enough energy to believe in yourself.

Meaningful work cannot be accomplished by sprinting full speed five days a week. It’s a marathon, and you’ve got to work that way and train that way. Get your rest, get your exercise, eat right, spend time with friends and family, and put your soul into your work.

Choose work that is meaningful and add energy. Add it every day. Add it openly. Add it purposefully. Add it genuinely. Add energy like you’re an aircraft carrier and others will get pulled along by your wake. Add energy like you’re bulldozer and others will get out of your way. Add energy like you’re contagious and others will be infected.

Image credit – anton borzov

The Top Three Enemies of Innovation – Waiting, Waiting, Waiting

All innovation projects take longer than expected and take more resources than expected. It’s time to change our expectations.

All innovation projects take longer than expected and take more resources than expected. It’s time to change our expectations.

With regard to time and resources, innovation’s biggest enemy is waiting. There. I said it.

There are books and articles that say innovation is too complex to do quickly, but complexity isn’t the culprit. It’s true there’s a lot of uncertainty with innovation, but, uncertainty isn’t the reason it takes as long as it does. Some blame an unhealthy culture for innovation’s long time constant, but that’s not exactly right. Yes, culture matters, but it matters for a very special reason. A culture intolerant of innovation causes a special type of waiting that, once eliminated, lets innovation to spool up to break-neck speeds.

Waiting? Really? Waiting is the secret? Waiting isn’t just the secret, it’s the top three secrets.

In a backward way, our incessant focus on productivity is the root cause for long wait times and, ultimately, the snail’s pace of innovation. Here’s how it goes. Innovation takes a long time so productivity and utilization are vital. (If they’re key for manufacturing productivity they must be key to innovation productivity, right?) Utilization of fixed assets – like prototype fabrication and low volume printed circuit board equipment – is monitored and maximized. The thinking goes – Let’s jam three more projects into the pipeline to get more out of our shared resources. The result is higher utilizations and skyrocketing queue times. It’s like company leaders don’t believe in queuing theory. Like with global warming, the theory is backed by data and you can’t dismiss queuing theory because it’s inconvenient.

One question: If over utilization of shared resources delays each prototype loop by two weeks (creates two weeks of incremental wait time) and you cycle through 10 prototype loops for each innovation project, how many weeks does it delay the innovation project? If you said 20 weeks you’re right, almost. It doesn’t delay just that one project; it delays all the projects that run through the shared resource by 20 weeks. Another question: How much is it worth to speed up all your innovation projects by 20 weeks?

In a second backward way, our incessant drive for productivity blinds us of the negative consequences of waiting. A prototype is created to determine viability of a new technology, and this learning is on the project’s critical path. (When the queue time delays the prototype loop by two weeks, the entire project slips two weeks.) Instead of working to reduce the cycle time of the prototype loop and advance the critical path, our productivity bias makes us work on non-critical path tasks to fill the time. It would be better to stop work altogether and help the company feel the pain of the unnecessarily bloated queue times, but we fill the time with non-critical path work to look busy. The result is activity without progress, and blindness to the reason for the schedule slip – waiting for the over utilized shared resource.

A company culture intolerant of uncertainty causes the third and most destructive flavor of waiting. Where productivity and over utilization reduce the speed of innovation, a culture intolerant of uncertainty stops innovation before it starts. The culture radiates negative energy throughout the labs and blocks all experiments where the results are uncertain. Blocking these experiments blocks the game-changing learning that comes with them, and, in that way, the culture create infinite wait time for the learning needed for innovation. If you don’t start innovation you can never finish. And if you fix this one, you can start.

To reduce wait time, it’s important to treat manufacturing and innovation differently. With manufacturing think efficiency and machine utilization, but with innovation think effectiveness and response time. With manufacturing it’s about following an established recipe in the most productive way; with innovation it’s about creating the new recipe. And that’s a big difference.

If you can learn to see waiting as the enemy of innovation, you can create a sustainable advantage and a sustainable company. It’s time to change expectations around waiting.

Image credit – Pulpolux !!!

Strategic Planning is Dead.

Things are no longer predictable, and it’s time to start behaving that way.

Things are no longer predictable, and it’s time to start behaving that way.

In the olden days (the early 2000s) the pace of change was slow enough that for most the next big thing was the same old thing, just twisted and massaged to look like the next big thing. But that’s not the case today. Today’s pace is exponential, and it’s time to behave that way. The next big thing has yet to be imagined, but with unimaginable computing power, smart phones, sensors on everything and a couple billion new innovators joining the web, it should be available on Alibaba and Amazon a week from next Thursday. And in three weeks, you’ll be able to buy a 3D printer for $199 and go into business making the next big thing out of your garage. Or, you can grasp tightly onto your success and ride it into the ground.

To move things forward, the first thing to do is to blow up the strategic planning process and sweep the pieces into the trash bin of a bygone era. And, the next thing to do is make sure the scythe of continuous improvement is busy cutting waste out of the manufacturing process so it cannot be misapplied to the process of re-imagining the strategic planning process. (Contrary to believe, fundamental problems of ineffectiveness cannot be solved with waste reduction.)

First, the process must be renamed. I’m not sure what to call it, but I am sure it should not have “planning” in the name – the rate of change is too steep for planning. “Strategic adapting” is a better name, but the actual behavior is more akin to probe, sense, respond. The logical question then – what to probe?

[First, for the risk minimization community, probing is not looking back at the problems of the past and mitigating risks that no longer apply.]

Probing is forward looking, and it’s most valuable to probe (purposefully investigate) fertile territory. And the most fertile ground is defined by your success. Here’s why. Though the future cannot be predicted, what can be predicted is your most profitable business will attract the most attention from the billion, or so, new innovators looking to disrupt things. They will probe your business model and take it apart piece-by-piece, so that’s exactly what you must do. You must probe-sense-respond until you obsolete your best work. If that’s uncomfortable, it should be. What should be more uncomfortable is the certainty that your cash cow will be dismantled. If someone will do it, it might as well be you that does it on your own terms.

Over the next year the most important work you can do is to create the new technology that will cause your most profitable business to collapse under its own weight. It doesn’t matter what you call it – strategic planning, strategic adapting, securing the future profitability of the company – what matters is you do it.

Today’s biggest risk is our blindness to the immense risk of keeping things as they are. Everything changes, everything’s impermanent – especially the things that create huge profits. Your most profitable businesses are magnates to the iron filings of disruption. And it’s best to behave that way.

Image credit – woodleywonderworks

Compete with No One

Today’s commercial environment is fierce. All companies have aggressive growth objectives that must be achieved at all costs. But there’s a problem – within any industry, when the growth goals are summed across competitors, there are simply too few customers to support everyone’s growth goals. Said another way, there are too many competitors trying to eat the same pie. In most industries it’s fierce hand-to-hand combat for single-point market share gains, and it’s a zero sum game – my gain comes at your loss. Companies surge against each other and bloody skirmishes break out over small slivers of the same pie.

Today’s commercial environment is fierce. All companies have aggressive growth objectives that must be achieved at all costs. But there’s a problem – within any industry, when the growth goals are summed across competitors, there are simply too few customers to support everyone’s growth goals. Said another way, there are too many competitors trying to eat the same pie. In most industries it’s fierce hand-to-hand combat for single-point market share gains, and it’s a zero sum game – my gain comes at your loss. Companies surge against each other and bloody skirmishes break out over small slivers of the same pie.

The apex of this glorious battle is reached when companies no longer have points of differentiation and resort to competing on price. This is akin to attrition warfare where heavy casualties are taken on both sides until the loser closes its doors and the winner emerges victorious and emaciated. This race to the bottom can only end one way – badly for everyone.

Trench warfare is no way for a company to succeed, and it’s time for a better way. Instead of competing head-to-head, it’s time to compete with no one.

To start, define the operating envelope (range of inputs and outputs) for all the products in the market of interest. Once defined, this operating envelope is off limits and the new product must operate outside the established design space. By definition, because the new product will operate with input conditions that no one else’s can and generate outputs no one else can, the product will compete with no one.

In a no-to-yes way, where everyone’s product says no, yours is reinvented to say yes. You sell to customers no one else can; you sell into applications no one else can; you sell functions no one else can. And in a wicked googly way, you say no to functions that no one else would dare. You define the boundary and operate outside it like no one else can.

Competing against no one is a great place to be – it’s as good as trench warfare is bad – but no one goes there. It’s straightforward to define the operating windows of products, and, once define it’s straightforward to get the engineers to design outside the window. The hard part is the market/customer part. For products that operate outside the conventional window, the sales figures are the lowest they can be (zero) and there are just as many customers (none). This generates extreme stress within the organization. The knee-jerk reaction is to assign the wrong root cause to the non-existent sales. The mistake – “No one sells products like that today, so there’s no market there.” The truth – “No one sells products like that today because no one on the planet makes a product like that today.”

Once that Gordian knot is unwound, it’s time for the marketing community to put their careers on the line. It’s time to push the organization toward the scary abyss of what could be very large new market, a market where the only competition would be no one. And this is the real hard part – balancing the risk of a non-existent market with the reward of a whole new market which you’d call your own.

If slugging it out with tenacious competitors is getting old, maybe it’s time to compete with no one. It’s a different battle with different rules. With the old slug-it-out war of attrition, there’s certainty in how things will go – it’s certain the herd will be thinned and it’s certain there’ll be heavy casualties on all fronts. With new compete-with-no-one there’s uncertainty at every turn, and excitement. It’s a conflict governed by flexibility, adaptability, maneuverability and rapid learning. Small teams work in a loosely coordinated way to test and probe through customer-technology learning loops using rough prototypes and good judgement.

It’s not practical to stop altogether with the traditional market share campaign – it pays the bills – but it is practical to make small bets on smart people who believe new markets are out there. If you’re lucky enough to have folks willing to put their careers on the line, competing with no one is a great way to create new markets and secure growth for future generations.

Image credit – mae noelle

Mike Shipulski

Mike Shipulski