Posts Tagged ‘Understanding Physics’

How To Create Clarity

Take a position. People will have to reconcile their thinking with yours and, together, the crew will deepen the collective understanding.

Take a position. People will have to reconcile their thinking with yours and, together, the crew will deepen the collective understanding.

Take an opposite position. Announce you are running a thought experiment and take a position that is opposite of the prevailing theory. Make it good. Make it deep. Do it for real. The prevailing theory will be strengthened, adapted, or discarded, and everything will be better for it.

Take an opposite position to your own prevailing wisdom. If there’s no one to play with, repeat the previous exercise with yourself. Give yourself the business. I bet you’ll teach yourself something and you’ll have better clarity on what you know and what you don’t.

Challenge someone’s best thinking. Announce you want to help them sharpen their thinking. Ask them why they think as they do. When they answer, ask them “why?” again. Repeat this process until you’ve asked “why?” five times. This process is aptly named The Five Whys. If they don’t feel uncomfortable, you’re doing it wrong.

Draw a picture. Announce that you want to help solve the problem. Ask “What’s the problem?” Then, draw a picture of the problem and show it to the crew. It won’t be right, but that’s okay. Ask them to fix the drawing so it captures the problem. Repeat the process until the picture looks like the problem. From there, the solving will come easily. Here’s an old blog post from 2013 with a simple “problem defining” template — How Engineers Create New Markets and another from 2017 that describes how to sketch a problem — See Differently To Solve Differently.

Make a Map. Check out these two blog posts — To Make Progress, Make a Map (2023) and The Half-Life of Our Maps (2014).

I think it’s better to be clear than correct. Clarity brings contrast; contrast creates conversation; and conversation begets understanding.

Clarity is king.

Image credit – Natashi Jay

Degrees of Not Knowing

You know you know, but you don’t.

You know you know, but you don’t.

You think you know, but you don’t.

You’re pretty sure you don’t know.

You know you don’t know, you think it’s not a problem that you don’t, but it is a problem.

You know you don’t know, you think it’s a problem that you don’t, but it isn’t a problem.

You don’t know, you don’t know that you don’t need to know yet, and you try.

You don’t know, you know you don’t need to know yet, and you wait.

You don’t know, you can’t know, you don’t know you can’t, and you try.

You don’t know, you can’t know, you know you can’t, and you wait.

Some skills you may want to develop….

To know when you know and when you don’t, ask yourself if you know and listen to the response.

To know if it’s a problem that you don’t know or if it isn’t, ask yourself, “Is it a problem that I don’t know?” If it isn’t, let it go. If it is, get after it.

To know if it’s not time to know or if it is, ask yourself, “Do I have to know this right now?” If it’s not time, wait. If it is time, let the learning begin. Trying to know before you need to is a big waste of time.

To know if you can’t know or if you can, ask yourself, “Can I know this?” and listen for the answer. Trying to learn when you can’t is the biggest waste of time.

Image credit — Dennis Skley

Seeing Growth A Different Way

Growing a company is challenging. Here are some common difficulties and associated approaches to improve effectiveness.

Growing a company is challenging. Here are some common difficulties and associated approaches to improve effectiveness.

No – The way we work is artisanal.

Yes – We know how to do the work innately.

It’s perfectly fine if the knowledge lives in the people.

Would you rather the knowledge resides in the people, or not know at all?

You know how to do the work. Celebrate that.

No – We don’t know how to scale.

Yes – We know how to do the work, and that’s the most difficult part.

It doesn’t make sense to scale before you’ve done it for the first time.

Socks then shoes, not shoes then socks.

If you can’t do it once, you can’t scale it. That’s a rule.

Give yourselves a break. You can learn how to scale it up.

No – We don’t know how to create the right organizational structure.

Yes – We get the work done, despite our informal structure.

Your team grew up together, and they know how to work together.

Imagine how good you’ll be with a little organizational structure!

There is no “right” organizational structure. Add what you need where you need it.

Don’t be so hard on yourselves. Remember, you’re getting the work done.

No – We don’t have formal production lines.

Yes – Our volumes are such that it’s best to keep the machines in functional clusters.

It’s not time for you to have production lines. You’re doing it right.

When production volume increases, it will be time for production lines.

Go get the business so you can justify the production lines.

No – We have too many projects. It was easier when we had a couple of small projects.

Yes – We have a ton of projects that could take off!

Celebrate the upside. This is what growth feels like.

When the projects hit big, you’ll have the cash for the people and resources you need.

Would you rather the projects take off or fall flat?

Be afraid, celebrate the upside, and go get the projects.

No – We need everything.

Yes – Our people, processes, and systems are young AND we’re getting it done!

Assess the work, define what you need, take the right first bite, and see how it goes.

Reassess the work, define the next right bite, put it in place, and see how it goes.

Repeat.

This is The Way.

Attitude matters. Language matters. Approach matters. People matter.

Image credit — Eric Huybrechts (Temple of Janus)

How To Put The Business Universe On One Page

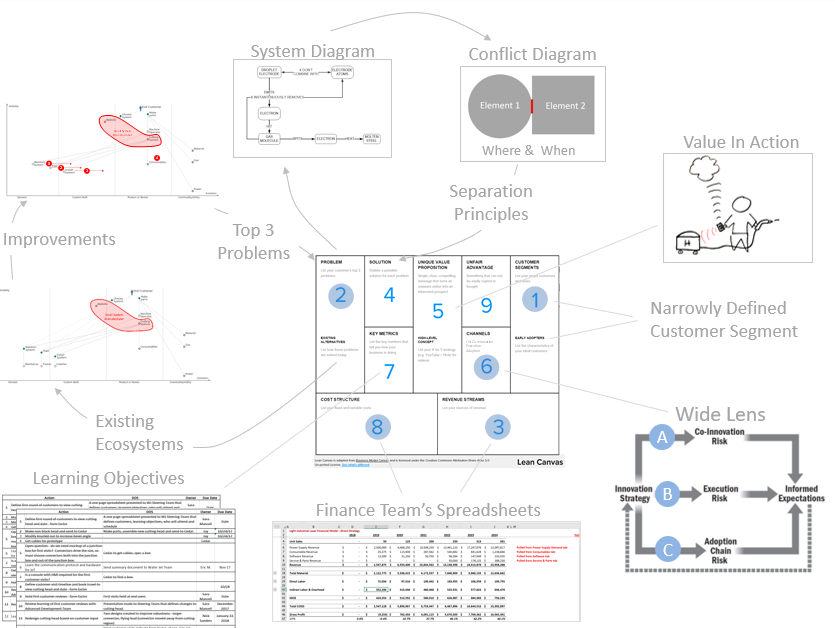

When I want to understand a large system, I make a map. If the system is an ecosystem, I combine Wardley Maps by Simon Wardley with Wide Lens / Winning The Right Game by Ron Adner. On Wardley maps, activities and actors are placed on the map, and related elements are connected. On the left are infant and underdeveloped elements, and on the right are fully developed / commodity elements. It’s like an S-curve that’s been squished flat.

When I want to understand a large system, I make a map. If the system is an ecosystem, I combine Wardley Maps by Simon Wardley with Wide Lens / Winning The Right Game by Ron Adner. On Wardley maps, activities and actors are placed on the map, and related elements are connected. On the left are infant and underdeveloped elements, and on the right are fully developed / commodity elements. It’s like an S-curve that’s been squished flat.

Wide Lens prompts you to consider co-innovation (who needs to innovate for you to be successful) and adoption (who needs to believe your idea is a good one). Winning The Right Game makes you think through the sequence of attracting partners like a visual time-lapse of the ecosystem’s evolution. This is a killer combination that demands you put the whole system on one page – all the players/partners, all the activities sorted by maturity, all the interactions, and the evolution of the partner network and maturity of the system elements. This forces a common understanding of the ecosystem. There’s no way out. Did I say it must fit on one page?

When the large system is a technological system, I make a map. I use the best TRIZ book (Innovation On Demand) by Victor Fey. A functional analysis is performed on the system using noun-verb pairs that are strung together to represent how the system behaves. If you want to drive people crazy, this is the process for you. It requires precise words for each noun (element) and verb (action) pair, and the pairs must hang together in a way that represents the physical system. There can be only one description of the system, and the fun and games don’t stop until the team converges on a single representation of the system. It’s all good fun until someone loses an eye.

When I want to understand a business/technology/product/service offering that has not been done before (think startup), I use Lean Canvas by Ash Maurya. The Lean Canvas requires you to think through all elements of the system and forces you to put it on one page. (Do you see a theme here?) Value proposition, existing alternatives, channel to market, customer segments, metrics, revenue, costs, problems, and solutions – all of them on one page.

And then to blow people’s minds, I combine Wardley Maps, Wide Lens, Winning The Right Game, functional analysis of TRIZ, value in action, and Lean Canvas on one page. And this is what it looks like.

Ash’s Lean Canvas is the backplane. Ron’s Wide Lens supports 6 (Channel), forcing a broader look than a traditional channel view. Ron’s Winning The Right Game and Simon’s Wardley Map are smashed together to support 2 (Existing Alternatives/Problems). A map is created for the existing system with system elements (infants on the left, retirees on the right) and partners/players, which are signified by color (red blob). Then, a second map is created to define the improvements to be made (red circles with arrows toward a more mature state). Victor’s Functional Analysis/System diagram defines the problematic system, and TRIZ tools, e.g., Separation Principles, are used to solve the problem.

When I want to understand a system (ecosystem or technological system), I make a map. And when I want to make a good map, I put it on one page. And when I want to create a new technological system that’s nested in a new business model that’s nested in a new ecosystem, I force myself to put the whole universe on one page.

Image credit – Giuseppe Zeta

Good Teachers Are Better Than Good

Good teachers change your life. They know what you know and bring you along at a pace that’s right for you, not too slowly that you’re bored and not too quickly that your head spins. And everything they do is about you and your learning. Good teachers prioritize your learning above all else.

Good teachers change your life. They know what you know and bring you along at a pace that’s right for you, not too slowly that you’re bored and not too quickly that your head spins. And everything they do is about you and your learning. Good teachers prioritize your learning above all else.

Chris Brown taught me Axiomatic Design. He helped me understand that design is more than what a product does. All meetings and discussions with Chris started with the three spaces – Functional Requirements (FRs) what it does, Design Parameters (DPs) what it looks like, and Process Variables (PVs) how to make it. This was the deepest learning of my professional life. To this day, I am colored by it. And the second thing he taught me was how to recognize functional coupling. If you change one input to the design and two outputs change, that’s functional coupling. You can manage functional coupling if you can see it. But if you can’t see it, you’re hosed. Absolutely hosed.

Vicor Fey taught me TRIZ. He helped me understand the staggering power of words to limit and shape our thinking. I will always remember when he passionately expressed in his wonderful accent, “I hate words!” And to this day, I draw pictures of problems and I avoid words. And the second thing he taught me is that a problem always exists between two things, and those things must touch each other. I make people’s lives miserable by asking – Can you draw me a picture of the problem? And, Which two system elements have the problem, and do they touch each other? And the third thing he taught me was to define problems (Yes, Victor, I know I should say conflicts.) in time. This is amazingly powerful. I ask – “Do you want to solve the problem before it happens, while it happens, or after it happens?” Defining the problem in time is magically informative.

Don Clausing taught me Robust Design. He helped me understand that you can’t pass a robustness test. He said, “If you don’t break it, you don’t know how good it is.” He was an ornery old codger, but he was right. Most tests are stopped before the product fails, and that’s wrong. He also said, “You’ve got to test the old design if you want to know if the new one is better.” To this day, I press for A/B testing, where the old design and new design are tested against the same test protocol. This is much harder than it sounds and much more powerful. He taught me to test designs at stress levels higher than the operating stresses. He said, “Test it, break it, and improve it. And when you run out of time, launch it.” And, lastly, he said, “Improve robustness at the expense of predicting it.” He gave zero value to statistics that predict robustness and 100% value to failure mode-based testing of the old design versus the new one.

The people I work with don’t know Chris, Victor, or Don. But they know the principles I learned from them. I’m a taskmaster when it comes to FRs-DPs-PVs. Designs must work well, be clearly defined by a drawing, and be easy to make. And people know there’s no place in my life for functional coupling. My coworkers know to draw a picture of the problem, and it better be done on one page. And they know the problem must be shown to exist between two things that touch. And they know they’ll get the business from me if they don’t declare that they’re solving it before, during, or after. They know that all new designs must have A/B test results, and the new one must work better than the old one. No exceptions.

I am thankful for my teachers. And I am proud to pass on what they gave me.

Image credit — Christof Timmermann

Two Tricks to Improve Understanding of New Ideas

When you want someone to understand your new idea, draw a picture for yourself. Set the constraint that you cannot use words on the page. Shapes, arrows, cartoons – yes. Words – no. Once you’re convinced your one-pager captures your idea, set another constraint. When you show your picture to someone, you cannot speak. Your one-page picture must stand on its own. I think you’ll find that this second constraint will cause you to improve your image, which will help others (and you) better understand your idea. You can use your words when you explain your one-pager to your target audience, which will improve clarity and understanding.

When you want someone to understand your new idea, draw a picture for yourself. Set the constraint that you cannot use words on the page. Shapes, arrows, cartoons – yes. Words – no. Once you’re convinced your one-pager captures your idea, set another constraint. When you show your picture to someone, you cannot speak. Your one-page picture must stand on its own. I think you’ll find that this second constraint will cause you to improve your image, which will help others (and you) better understand your idea. You can use your words when you explain your one-pager to your target audience, which will improve clarity and understanding.

When you want someone to understand that your new idea is possible, build a prototype and do a demo. Use your one-pager to create a storyboard of the demo. The storyboard can be a series of cartoons that describe what will happen during the demo. And like with the one-pager, your storyboard cannot use words. And once you think your storyboard communicates your idea, set the constraint that you cannot speak during the demo, and try to improve the storyboard to support a no-word demo. You can use your words during the demo to further improve clarity and understanding.

Make no mistake, the one-pager and the storyboard are for you. They will help you better understand your idea so you can help people understand it better.

Image credit – Jennifer Moo

How I Develop Engineering Leaders

For the past two decades, I’ve actively developed engineering leaders. A good friend asked me how I do it, so I took some time to write it down. Here is the curriculum in the form of How Tos:

For the past two decades, I’ve actively developed engineering leaders. A good friend asked me how I do it, so I took some time to write it down. Here is the curriculum in the form of How Tos:

How to build trust. This is the first thing. Always. Done right, the trust-based informal networks are stronger than the formal organization chart. Done right, the informal networks can protect the company from bad decisions. Done right, the right information flows among the right engineers at the right time so the right work happens in the right way.

How to decide what to do next. This is a broad one. We start with a series of questions: What are we doing now? What’s the problem? How do you know? What should we do more of? What should we do less of? What resources are available? When must we be done?

How to map the current state. We don’t define the idealized future state or the North Star, we start with what’s happening now. We make one-page maps of the territory. We use drawings, flow charts, boxes/arrows, and the fewest words. And we take no action before there’s agreement on how things are. The value of GPS isn’t to define your destination, it’s to establish your location. That’s why we map the current state.

How to build momentum. It’s easy to jump onto a moving steam train, but a stationary one is difficult to get moving. We define the active projects and ask – How might we hitch our wagon to a fast-moving train?

How to start something new. We start small and make a thought-provoking demo. The prototype forces us to think through all the elements, makes things real, and helps others understand the concept. If that doesn’t work, we start smaller.

How to define problems so we can solve them easily. We define problems with blocks and arrows, and limit ourselves to one page. The problem is defined as a region of contact between two things, and we identify it with the color red. That helps us know where the problem is and when it occurs. If there are two problems on a page, we break it up into two pages with one problem. Then we decide to solve the problem before, during, or after it occurs.

How to design products that work better and cost less. We create Pareto charts of the cost of the existing product (cost by subassembly and cost by part) and set a cost reduction goal. We create Pareto charts of the part count of the existing product (part count by subassembly and part count by individual part number) and define a goal for part count reduction. We define test protocols that capture the functionality customers care about. We test the existing product and set performance improvement goals for the new one. We test the new product using the same protocols and show the data in a simple A-B format. We present all this data at formal design reviews.

How to define technology projects. We define how the customer does their work. We then define the evolutionary history of our products and services, and project that history forward. For lines of goodness with trajectories that predict improvement, we run projects to improve them. For lines of goodness with stalled trajectories, we run projects to establish new technologies and jump to the next S-curve. We assess our offerings for completeness and create technologies to fill the gap.

How to file the right patents. We ask these questions: How quickly will the customer notice the new functionality or benefit? Once recognized, will they care? Will the patent protect high-volume / high-margin consumables? There are more questions, but these are the ones we start with. And the patent team is an integral part of the technology reviews and product development process.

How to do the learning. We start with the leader’s existing goals and deliverables and identify the necessary How Tos to get their work done. There are no special projects or extra work.

If you’re interested in learning more about the curriculum or how to enroll, send me an email mike@shipulski.com.

Image credit — Paul VanDerWerf

How To Make Progress

Improvement is progress. Improvement is always measured against a baseline, so the first thing to do is to establish the baseline, the thing you make today, the thing you want to improve. Create an environment to test what you make today, create the test fixtures, define the inputs, create the measurement systems, and write a formal test protocol. Now you have what it takes to quantify an improvement objectively. Test the existing product to define the baseline. No, you haven’t improved anything, but you’ve done the right first thing.

Improvement is progress. Improvement is always measured against a baseline, so the first thing to do is to establish the baseline, the thing you make today, the thing you want to improve. Create an environment to test what you make today, create the test fixtures, define the inputs, create the measurement systems, and write a formal test protocol. Now you have what it takes to quantify an improvement objectively. Test the existing product to define the baseline. No, you haven’t improved anything, but you’ve done the right first thing.

Improving the right thing to make progress. If the problem invalidates the business model, stop what you’re doing and solve it right away because you don’t have a business if you don’t solve it. Any other activity isn’t progress, it’s dilution. Say no to everything else and solve it. This is how rapid progress is made. If the customer won’t buy the product if the problem isn’t solved, solve it. Don’t argue about priorities, don’t use shared resources, don’t try to be efficient. Be effective. Do one thing. Solve it. This type of discipline reduces time to market. No surprises here.

Avoiding improvement of the wrong thing to make progress. For lesser problems, declare them nuisances and permit yourself to solve them later. Nuisances don’t have to be solved immediately (if at all) so you can double down on the most important problems (speed, speed, speed). Demoting problems to nuisances is probably the most effective way to accelerate progress. Deciding what you won’t do frees up resources and emotional bandwidth to make rapid progress on things that matter.

Work the critical path to make progress. Know what work is on the critical path and what is not. For work on the critical path, add resources. Pull resources from non-critical path work and add them to the critical path until adding more slows things down.

Eliminate waiting to make progress. There can be no progress while you wait. Wait for a tool, no progress. Wait for a part from a supplier, no progress. Wait for raw material, no progress. Wait for a shared resource, no progress. Buy the right tools and keep them at the workstations to make progress. Pay the supplier for priority service levels to make progress. Buy inventory of raw materials to make progress. Ensure shared resources are wildly underutilized so they’re available to make progress whenever you need to. Think fire stations, fire trucks, and firefighters.

Help the team make progress. As a leader, jump right in and help the team know what progress looks like. Praise the crudeness of their prototypes to help them make them cruder (and faster) next time. Give them permission to make assumptions and use their judgment because that’s where speed comes from. And when you see “activity” call it by name so they can recognize it for themselves, and teach them how to turn their effort into progress.

Be relentless and respectful to make progress. Apply constant pressure, but make it sustainable and fun.

Image credit — Clint Mason

Swimming In New Soup

You know the space is new when you don’t have the right words to describe the phenomenon.

You know the space is new when you don’t have the right words to describe the phenomenon.

When there are two opposite sequences of events and you think both are right, you know the space is new.

You know you’re thinking about new things when the harder you try to figure it out the less you know.

You know the space is outside your experience but within your knowledge when you know what to do but you don’t know why.

When you can see the concept in your head but can’t drag it to the whiteboard, you’re swimming in new soup.

When you come back from a walk with a solution to a problem you haven’t yet met, you’re circling new space.

And it’s the same when know what should be but it isn’t – circling new space.

When your old tricks are irrelevant, you’re digging in a new sandbox.

When you come up with a new trick but the audience doesn’t care – new space.

When you know how an experiment will turn out and it turns out you ran an irrational experiment – new space.

When everyone disagrees, the disagreement is a surrogate for the new space.

It’s vital to recognize when you’re swimming in a new space. There is design freedom, new solutions to new problems, growth potential, learning, and excitement. There’s acknowledgment that the old ways won’t cut it. There’s permission to try.

And it’s vital to recognize when you’re squatting in an old space because there’s an acknowledgment that the old ways haven’t cut it. And there’s permission to wander toward a new space.

Image credit — Tambaco The Jaguar

Why Hardware Is Hard For Startups And What to Do About It

Software may be eating the world, but the hardware elements of a startup’s work define when lunch is served.

Software may be eating the world, but the hardware elements of a startup’s work define when lunch is served.

Hardware takes longer than software. With hardware, after the product and its parts are designed, companies are vetted/selected to make the parts; contracts are signed to make the parts; the parts are made; the parts are shipped; the parts are received; the parts are inspected; and the parts are put in their locators. Then, the manufacturing process is defined, the manufacturing tooling is designed and purchased; the manufacturing documentation is created; the final test system is designed and built; and the parts are assembled into the product. Then, the product is run through final test and tested for robustness. After it’s learned the manufacturing process created too much variation and the insufficient robustness manifests, the manufacturing process and its documentation are changed to reduce variation; the parts that failed are redesigned, purchased, made, shipped, and received; and the next iteration of the product is built and tested. This process is repeated until the product is robust and the manufacturing process is repeatable. This is why hardware takes longer than software.

If the software is done but the hardware isn’t, the software must wait for the hardware and the customer must wait for the finished product. To get the hardware done faster, recognize that redesign loops are part of the game and invest in the capability to iterate quickly. Line up the suppliers to make parts quickly; keep utilization low on the support resources so they can jump on the work when it arises (think fire stations who can respond quickly when there’s a fire); and avoid part-time resources on the critical path. There may be other things to focus on, but only after taking care of these three.

Software may be eating the world, but the hardware elements of a startup’s work govern the cost of getting to the dinner table.

Hardware costs more to make than software. Hardware is made of steel, aluminum, injection molded plastics, and rare earth elements, all of which cost money. And because startups do things that have not been done before, the materials can be special (costly). And unlike software, the marginal cost of an incremental unit is non-zero. With hardware, if you want to make another one you’ve got to buy more of the materials; you have to pay people to make it; you have to buy/build the manufacturing system; you have to buy the measurement systems and engineering infrastructure; and you have to pay people to break-test-fix the product until it’s ready.

What’s a startup to do?

To do hardware faster, focus on learning. And to do hardware more cost-effectively, focus on learning.

For both time and money, learning efficiency is a good starting point. The most efficient learning is the learning you don’t have to do, so be ruthless in how you decide what you DON’T learn. Where possible, declare all but the most vital problems as annoyances and save them for later. (Annoyances don’t require learning.) This will concentrate your precious resources on fewer problems, improve your learning rate, and keep costs to a minimum.

Here’s a good test to decide if the learning is worth learning. Ask yourself “If we accomplish this learning objective, how will the customer benefit?” If there is low or no customer benefit, say no to the learning objective. If there is medium customer benefit, say no to the learning objective. If there is significant customer benefit, do the learning.

For those learning objectives that make it through the gauntlet, learn what you need to learn, but no more. To do this, create a formal learning objective: “We want to learn [enter learning objective here].” With learning objectives, the tighter the better. And define the criteria for decision making: “If the result of the test is [define objective measurement here], we will decide [enter decision here].” With decision criteria, the clearer the better.

Learn effectively, not elegantly. Be bold, rough, and crude with how you learn. Design tests that take advantage of the resources you have on hand so you can learn quickly. If you can run a crude test in one hour and the perfect test will take a week, run three crude tests and be done by the end of the day.

Learn with less confidence and more judgment. If a wrong decision can be overcome quickly and with low cost, be less confident and use more judgment.

Whether driven by hardware, software, or the integration of both, project completion is governed by the critical path. And with longer time constants, it’s more likely that the hardware defines the critical path. The total cost of the project is the sum of the three costs: software, hardware, and integration. And because hardware requires expensive materials, factories, engineering labs, people to run the tests, and people to make the products, hardware is likely a large percentage of the project costs.

Image credit — Günter Hentschel

The Difficulty of Goal Setting in Domains of High Uncertainty

When you work in domains of high uncertainty, creating goals for the next year is exceptionally difficult.

When you work in domains of high uncertainty, creating goals for the next year is exceptionally difficult.

When you try to do something that hasn’t been done before, things may blow up instantly, things may work out after two years of hard work, or things may never work. So, how do you create the goal for that work? Do you give yourself one month to complete the work? And things haven’t worked out at the end of the month, do you stop the work or do you keep going? If it blows up instantly, but you think you know why, do you keep going? Do you extend the due date for the goal? At the start of the work, should the timeline have been set to one year instead of one month? And who decides that? And how do they decide?

When you have to create your goals for something that hasn’t been done before and the objectives of the work are defined by another team, yet that team hasn’t done the prework and cannot provide those objectives, what do you do? Do you create a goal for the other team to define the objectives? And what if you have no control over that team’s priorities and you don’t know when (or if) they’ll provide the needed information? What does a goal look like when you don’t know the objectives of the work nor do you know when (or if) you’ll get that information. Can you even create a goal for the work when you don’t know what that work is? And how do you estimate a completion date or the resource requirements (both the flavor and quantity) when you don’t know the objectives? What does that goal look like?

When you have to create your goals for a team of ten specialized people who each have unique skills, but you don’t know the objectives of the work, when that work can start, or when that work will finish, how do you cascade the team’s goals to each team members? What do their goals look like? Is the first goal to figure out the goal? How many goals does it take to fill up their year when you don’t know what the work is or how long it will take?

When working in domains of high uncertainty, the goals go like this: define the system as it is, define something you want to improve, try to improve it, and then do the next right thing. Unfortunately, that doesn’t fit well with the traditional process of setting yearly goals.

And your two questions should be: How do you decide what to improve? and How do you choose the next right thing?

Image credit — Rab Lawrence

Mike Shipulski

Mike Shipulski