On Independence

Independence for a country is about choice. A country wants to be able to make choices to better itself, to control its own destiny. A country wants to feel like it has freedom to do what it thinks is right. Hopefully, a country thinks it’s a good to provide for its citizens in a long term sense. We can disagree what is best, but a good country makes an explicit choice about what it think is right and takes responsibility for its choices. For a country, the choices should be grounded in the long term.

Independence for a country is about choice. A country wants to be able to make choices to better itself, to control its own destiny. A country wants to feel like it has freedom to do what it thinks is right. Hopefully, a country thinks it’s a good to provide for its citizens in a long term sense. We can disagree what is best, but a good country makes an explicit choice about what it think is right and takes responsibility for its choices. For a country, the choices should be grounded in the long term.

Independence for a company is about choice. Like a country, a company wants control over its own destiny. A company wants to feel like it has freedom to do what’s right. A company wants to decide what’s right and wants the ability to act accordingly. There are lots of management theories on what’s right, but the company wants to be able to choose. Like it or not, the company will be accountable for its choices, as measured by stock price or profit.

And with children, independence is about choice. Children, too, want control over their own destiny, but they score low on the responsibility scale. And that’s why children earn responsibility over time – get a little, don’t get hurt, and get a little more. They don’t know what’s good for them, but don’t let that get in the way of wanting control over their own destiny. That’s why parents exist.

Independence is about the ability to choose. But there’s a catch. With independence comes responsibility – responsibility for the choice. With children, there’s insufficient responsibility because they just don’t care. And with employees in a company, there’s insufficient responsibility for another reason – fear of failure. I’m not sure about countries.

Independence is a two way street – choice and responsibility. And independence is bound by constraints. (There are unalienable rights, but unconstrained independence isn’t one of them.) For more independence, push hard on constraints; for more independence, take responsibility; for more independence, make more choices (and own the consequences).

Happy Independence Day.

Small Is Good, And Powerful

If lean has taught us anything, it’s smaller is better. Smaller machines, smaller factories, smaller teams, smaller everything.

If lean has taught us anything, it’s smaller is better. Smaller machines, smaller factories, smaller teams, smaller everything.

The famous Speaker of the House, Tip O’Neill, said all politics are local. He meant all action happens at the lowest levels (in the districts and neighborhoods), where everyone knows everyone, where the issues are well understood, and the fundamentals are not just talked about, they’re lived. It’s the same with manufacturing. But I’m not talking about local in the geography sense; I’m talking about the neighborhood sense. When manufacturing is neighborhood-local, it’s small, tight, focused and knowledgeable.

We mistakenly think about manufacturing strictly as the process of making things—it’s far more. In the broadest sense, manufacturing is everything: innovation, design, making and service. It’s this broad-sense manufacturing that will deliver the next economic revolution.

Previously, I described how big companies break themselves into smaller operating units. They recognize lean favors small, and they break themselves up for competitive advantage. They want to become a collective of small companies with the upside of small without of the downside of big. Yet with small companies, there’s an urge to be big.

Lean says smaller is better and more profitable. Lean says small companies have an advantage because they’re already small. Lean says small companies should stay small (neighborhood small) and be more of what they are.

Small companies have a size advantage. Their smaller scope improves focus and alignment. It’s easier to define the mission, communicate it, and work toward it. It’s easier to mobilize the neighborhood. It’s clearer when things go off track and easier to get things back on track. At the lowest level, smaller companies zero in on problems and fix them. At the highest, they align themselves with their mission. These are important advantages, but not the most important.

The real advantage is deep process knowledge. Smaller companies have less breadth and more depth, which allows them to focus energy on the work and develop deep process knowledge. Many large manufacturers have lost process knowledge over the years. Small companies tend to develop and retain more of it. We’ve forgotten the value of deep process knowledge, but as companies look for competitive advantage, its stock is rising.

Lean wants small companies to build on that strength. To take it to the next level, lean wants companies to think about manufacturing in the more-than-making sense and use that deep process knowledge to influence the product itself. Lean wants suppliers to inject their process knowledge into their customers’ product development process to radically reduce material cost and help the product sprint through the factory.

The ultimate advantage of deep process knowledge is realized when small companies use it to design products. It’s realized when people who know the process fundamentals work respectfully with their neighbors who design the product. The result is deeper process knowledge and a far more profitable product. Big companies like to work with smaller companies who can design and make.

Tip O’Neill and lean agree. All manufacturing is local. And this local nature drives a focus on the fundamentals and details. Being neighborhood-local is easier for small companies because their scope is smaller, which helps them develop and retain deep process knowledge.

Lean wants companies to be small—neighborhood-small. When small companies build on a foundation of deep process knowledge, sales grow. Lean wants sales growth, but it also wants companies to reduce their size in the neighborhood sense.

The People Business

Regardless of industry, product, or country, we’re in the people business.

Regardless of industry, product, or country, we’re in the people business.

Got a problem? Problems are solved by people, and our first word is usually – who. Who has fixed something like this before? Who can make the problem go away? Who has the chops to pull it off? Our first thought is about people.

Want something done? Work doesn’t do itself, people do work. Whether we want a wrench turned or a project run, our first thought is about people.

Need help? People help people. First thought – people.

Our businesses run on people. Factory workers are people, suppliers are people, leaders are people, and so are most managers. Day-to-day we are neighborhoods that make stuff and families that provide services. (Some of us spend more time with our coworkers than our families.)

But lately, in the name of productivity, there’s an unnatural shift from people-thinking to machine-thinking.

Productivity is good, and we all need it. To get it, we standardize our work; we define step-wise business processes to mechanize; we create scripted approaches to drive out variability. All perfectly good machine-thinking, but we must be careful not to tip into a Frederick Taylor frenzy.

People are best at some things, and machines at others – we all know this. But we’ve got to keep it in front of us. Mechanize things that machines do best, and free up people to do more people-work – that’s the ticket. But we spend far more corporate bandwidth mechanizing work than people-izing.

People-work is governed by choice, feelings, relationships, and creativity. Even the best six sigma squad can’t mechanize that, nor should they try. But what if we invested in improving our people-work like we’ve invested in improving our machine-work? What if we allocated time for our people to improve their ability to decide? What if we had a sea of highly trained creativity experts (people) to help our people create? What if we taught our people how to foster deep personal relationships? Productivity squared.

We’ve got to remember that we’re in the people business and we always will be – relationships, choice, decisions, and feelings cannot be taken out of our work. And we’ve got to learn how to improve our people-work.

Improving people-work is different than improving machine-work (that’s for a different post), but the first tool in the toolbox is trust.

Just Start

Starting is scary – we’re afraid to get it wrong. And we let our fear block us from starting. And that’s strange, because there’s never certainty on the right way because every situation is different. Fact is, you will be wrong, it’s just a matter of how wrong. But even the level of wrongness is not important. What’s important is starting because starting gives us the opportunity to respond to our wrongness. And that’s the trick – our response to being wrong is progress. Start, be wrong, refocus, and go. Progress.

Starting is scary – we’re afraid to get it wrong. And we let our fear block us from starting. And that’s strange, because there’s never certainty on the right way because every situation is different. Fact is, you will be wrong, it’s just a matter of how wrong. But even the level of wrongness is not important. What’s important is starting because starting gives us the opportunity to respond to our wrongness. And that’s the trick – our response to being wrong is progress. Start, be wrong, refocus, and go. Progress.

The biggest impediment to finishing is starting. Don’t let perfection get in the way of progress. Just start.

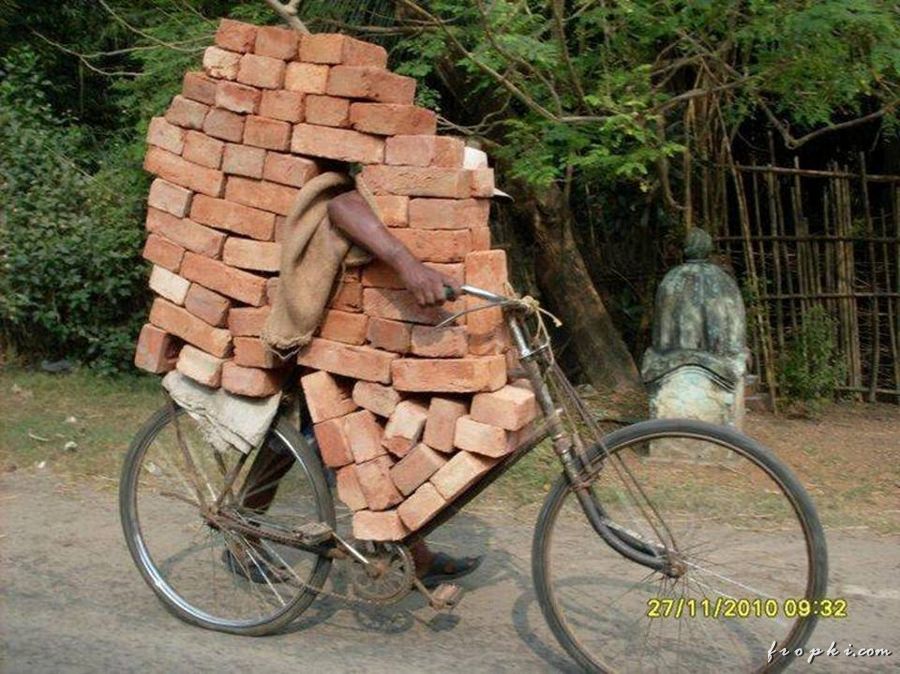

Impossible

Things aren’t impossible on their own, our thinking makes them so.

Things aren’t impossible on their own, our thinking makes them so.

Impossible is not about the thing itself, it’s a statement about our state of mind.

When we say impossible, we really say we lack confidence to try.

When we say impossible, we really say we are too afraid to try.

The mission of impossible is to shut down all possibility of possibility.

To soften it, we say almost impossible, but it’s the same thing.

When we say impossible, we make a big judgment – but not about the thing – about ourselves.

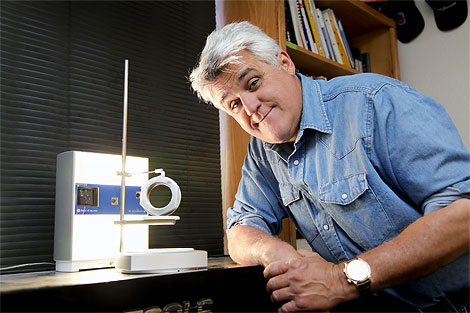

Less With Far Less

We don’t know the question, but the answer is innovation. And with innovation it’s more, more, more. Whether it’s more with less, or a lot more with a little more, it’s always more. It’s bigger, faster, stronger, or bust. It’s an enhancement of what is, or an extrapolation of what we have. Or it’s the best of product one added to product two. But it’s always more.

We don’t know the question, but the answer is innovation. And with innovation it’s more, more, more. Whether it’s more with less, or a lot more with a little more, it’s always more. It’s bigger, faster, stronger, or bust. It’s an enhancement of what is, or an extrapolation of what we have. Or it’s the best of product one added to product two. But it’s always more.

More-on-more makes radical shifts hard because with more-on-more we hold onto all functionality then add features, or we retain all features then multiply output. This makes it hard to let go of constraints, both the fundamental ones – which we don’t even see as constraints because they masquerade as design rules – and the little-known second class constraints – which we can see, but don’t recognize their power to block first class improvements. (Second class constraints are baggage that come with tangential features which stop us from jumping onto new S-curves for the first class stuff.)

To break the unhealthy cycle of more-on-more addition, think subtraction. Take out features and function. Distill to the essence. Decree guilty until proven innocent, and make your marketers justify the addition of every feature and function. Starting from ground zero, ask your marketers, “If the product does just one thing, what should it do?” Write it down as input to the next step.

Next, instead of more-on-more multiplication, think division. Divide by ten the minimum output of your smallest product. (The intent it to rip your engineers and marketers out of the rut that is your core product line.) With this fractional output, ask what other technologies can enable the functionality? Look down. Look to little technologies, technologies that you could have never considered at full output. Congratulations. You’ve started on your migration toward with less-with-far-less.

On the surface, less-with-far-less doesn’t seem like a big deal. And at first, folks roll their eyes at the idea of taking out features and de-rating output by ten. But its magic is real. When product performance is clipped, constraints fall by the wayside. And when the product must do far less and constraints are dismissed, engineers are pushed away from known technologies toward the unfamiliar and unreasonable. These unfamiliar technologies are unreasonably small and enable functionality with far less real estate and far less inefficiency. The result is radically reduced cost, size, and weight.

Less-with-far-less enables cost reductions so radical, new markets become viable; it makes possible size and weight reductions so radical, new levels of portability open unimaginable markets; it facilitates power reductions so radical, new solar technologies become viable.

The half-life of constraints is long, and the magic from less-with-far-less builds slowly. Before they can let go of what was, engineers must marinate in the notion of less. But when the first connections are made, a cascade of ideas follow and things spin wonderfully out of control. It becomes a frenzy of ideas so exciting, the problem becomes cooling their jets without dampening their spirit.

Less-with-far-less is not dumbed-down work – engineers are pushed to solve new problems with new technologies. Thermal problems are more severe, dimensional variation must be better controlled, and failure modes are new. In fact, less-with-far-less creates steeper learning curves and demands higher-end technologies and even adolescent technologies.

Our thinking, in the form of constraints, limits our thinking. Less-with-far-less creates the scarcity that forces us to abandon our constraints. Less-with-far-less declares our existing technologies unviable and demands new thinking. And I think that’s just what we need.

Untapped Power of Self

As a subject matter expert (SME), you have more power than you think, and certainly more than you demonstrate.

As a subject matter expert (SME), you have more power than you think, and certainly more than you demonstrate.

As an SME, you have special knowledge. Looking back, you know what worked, what didn’t, and why; looking forward, you know what should work, what shouldn’t, and why. There’s power in your special knowledge, but you underestimate it and don’t use it to move the needle.

As an SME, without your special knowledge there are no new products, no new technologies, and no new markets. Without it, it’s same-old, same-old until the competition outguns you. It’s time you realize your importance and behave that way.

As an SME, when you and your SME friends gang together, your company must listen. Your gang knows it all. From the system-level stuff to the most detailed detail, you know it. Remember, you invented the technology that powers your products. It’s time you behave that way.

As an SME, with your power comes responsibility – you have an obligation to use your power for good. Figure out what the technology wants, and do that; do the sustainable thing; do the thing that creates jobs; do what’s good for the economy; sit yourself in the future, look back, and do what you think is right.

As an SME, I’m calling you out. I trust you, now it’s time to trust yourself. And it’s time for you to behave that way.

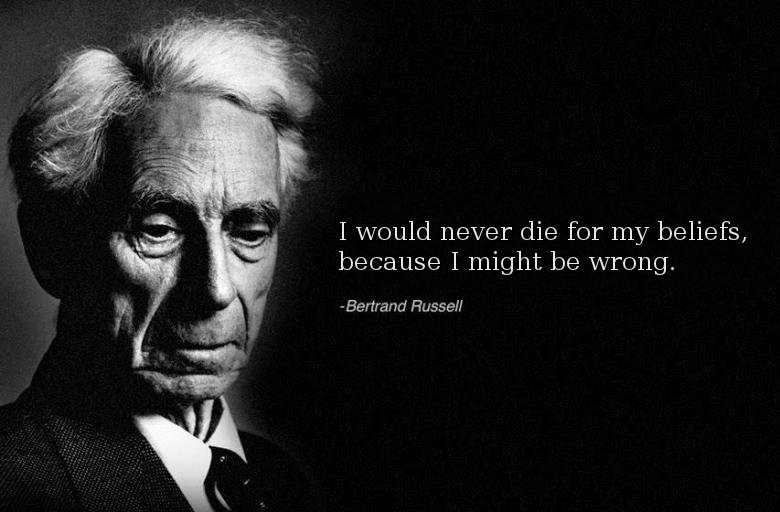

Beliefs Govern Ideas

Some ideas are so powerful they change you. More precisely, some ideas are so powerful you change your beliefs to fit them.

Some ideas are so powerful they change you. More precisely, some ideas are so powerful you change your beliefs to fit them.

These powerful ideas come in two strains: those that already align with your beliefs and those that contradict.

The first strain works subtly. While you think on the idea, your beliefs test it for safety. (They work in the background without your knowledge.) And if the idea passes the sniff test, and your beliefs feel safe, they let the subconscious sniffing morph into conscious realization – the idea fits your beliefs. The result: You now better understand your beliefs and you blossom, grow, and amplify yourself.

The second strain is subtle as a train wreck – a full frontal assault on your beliefs. This strain contradicts our beliefs and creates an emotional response – fear, anger, stress. And because these ideas threaten our beliefs, our beliefs reject them for safety’s sake. It’s like an autoimmune system for ideas.

But this autoimmune system has a back door. While it rejects most of the idea, for unknown reasons it passes a wisp to our belief system for sniffing. Like a vaccine, it wants to strengthen our beliefs against the strain. And in most cases, it works. But in rare cases, through deep introspection, our beliefs self-mutate and align with the previously contradicting idea. The result: You change yourself fundamentally.

Truth is, ideas are not about ideas; ideas are about beliefs. Our beliefs give life to ideas, or kill them. But we give ideas too much responsibility, and take too little. Truth is, we can change what we think and feel about ideas.

More powerfully, we can change what we think and feel about our beliefs, but only if we believe we can.

Make It Where You Sell It

Lean has rolled through our factories and generated profits at every turn. Now it’s time to get serious about savings and realize the next level of savings. Companies are pushing lean into the back office, but that won’t get it done. The savings will be good, but not great. After picking low-hanging factory fruit, there’s uncertainty around what’s next for lean.

Lean has rolled through our factories and generated profits at every turn. Now it’s time to get serious about savings and realize the next level of savings. Companies are pushing lean into the back office, but that won’t get it done. The savings will be good, but not great. After picking low-hanging factory fruit, there’s uncertainty around what’s next for lean.

Make it where you sell it, that’s next for lean. Like a central theorem, this simple phrase will become lean’s mantra, and it will change everything, including our organizations themselves. The big multi-national companies have already started their journey, and we can take our cues from them.

The major automakers have assembly plants on all continents – objective evidence of make it where you sell it. There are many benefits to make it where you sell it, but the top three are: speed, speed, speed. The automotive value stream without make it where you sell it: make a car, put it on a boat, deliver it to a dealer, and sell it. Make it where you sell it eliminates the boat: make it, deliver it, and sell it. Inventory is proportional to cycle time and eliminating the long boat ride shortens the value stream, improves response time and reduces inventory.

Make it where you sell it starts closest to the customer, and final assembly is the first to be established in-market. Engines and transmissions still ride the boat, but not for long. After final assembly, make it where you sell it targets big, heavy, expensive subassemblies, so expect in-market engine and transmission plants. (However, big ones like these may stay put for while due to technological, political, or cultural reasons.)

With one piece flow, right-sized machines, and short product runs, lean has taught us the most economic scale is far smaller than we’d imagined. We’ve learned for our factories smaller is better, and make it where you sell it extrapolates smaller-is-better to the organization itself. Here again, the big guys lead the way. Multinationals are breaking themselves into smaller units, right-sizing into smaller regional companies – still big, but smaller. Their in-country manufacturing creates nice tight feedback loops between customer and factory. And there’s an important benefit to the brand – it becomes a local brand. Not only can the brand better serve regional tastes, it provides goodwill in the form of jobs.

[Disclaimer: I don’t advocate outsourcing. I’m simply explaining the forces at work and their consequences.]

Lean cares about speed, not countries, and make it where you sell it causes jobs flow across company boarders. This is especiallylevant as countries compete for manufacturing jobs like their survival depended on them. For those countries that understand manufacturing jobs are the bedrock of a sustainable economy, make it where you sell it can be threatening. If you’re a country that doesn’t buy a lot of manufactured goods, you and your economy trouble – jobs will flow to where products are sold.

Make it where you sell it won’t stop at making, and will extend up stream. The next logical extension is design it where you sell it, R&D it where you sell it, and innovate it where you sell it. (The biggest companies are already doing this with regional R&D centers.) More jobs will flow across borders, but this time they’ll be the coveted thinking jobs.

Make it where you sell it is the guiding principle companies are using to become more responsive, more productive, and local. It has already broken the biggest companies into smaller ones. They’ve realized that the most economic scale is small, and they’re getting there using make it where you sell it.

Make it where you sell it will change all companies, even small ones. And the mantra for small companies: think narrow and deep.

I will hold a half-day Workshop on Systematic DFMA Deployment on June 13 in RI. (See bottom of linked page.) I look forward to meeting you in person.

Work The Rule

If the rule makes things take too long, do you follow it or shortcut it?

If the rule makes things take too long, do you follow it or shortcut it?

If the reason for the rule is no longer, do you follow it or declare it unreasonable?

If you don’t understand the rule do you work to understand it, or conveniently trespass?

If you don’t follow the rule, does that say something about the rule, or you?

When is a rule a rule and when is it shackles?

When it comes to law, physics, and safety, a rule is a rule.

If you’re limited by the rule, is it bad? (Isn’t far worse if you don’t realize it?)

What if the solution demands unruliness?

If you don’t follow rules, is it okay to make them?

What if a culture is so strong it rules out most everything, except following the rules?

What if a culture is so strong it demands you make the rules?

When it comes to rules, there’s only one rule – You decide.

I will hold a Workshop on Systematic DFMA Deployment on June 13 in RI. (See bottom of linked page.) I look forward to meeting you in person.

The Forbidden Fruit of Failure

We’ve mapped failure to the wrong words. And this mis-mapping is so strong and deep that un-mapping seems unlikely. I propose failure, as a word, be scratched from the dictionary.

We’ve mapped failure to the wrong words. And this mis-mapping is so strong and deep that un-mapping seems unlikely. I propose failure, as a word, be scratched from the dictionary.

Failure is learning in the form of experiments (including the thought kind) with outcomes different than theorized, where the outcomes create a more complete understanding of theory, or learning.

Wrong is mapped to failure, but failure should be mapped with – different than our best understanding.

Newness is mapped to failure. Replace failure with learning and the mapping is right – more newness, more learning. This is why tolerance of failure (and newness) is a must – no newness, no failure, no learning.

Risk is mapped to failure. Replace failure with learning and the mapping is right – more risk, more learning. Risk cannot be forbidden, if we’re to learn.

Risk and newness are mapped to late, and, guilt by association, failure is mapped to late. Replace failure with learning and the mapping is right – learn fast to avoid being late. And now, after several paragraphs of un-mapping, hopefully the re-substitution makes sense – fail fast to avoid being late.

Failure isn’t failure, failure is learning.

Mike Shipulski

Mike Shipulski