Lasting Behavioral Change

Whether it’s innovation, creativity, continuous improvement, or discontinuous improvement, it’s all about cultural change, and cultural change is about change in behavior.

Whether it’s innovation, creativity, continuous improvement, or discontinuous improvement, it’s all about cultural change, and cultural change is about change in behavior.

With the police state approach, detailed processes are created and enforced; rules are created and monitored; and training is dealt out and attendance taken. Yes, behavior is changed, but it’s fleeting. Take your eye off the process, old behavior slips through the fence; look the other way from the rules, old behavior clips the barbed wire and climbs over the wall. To squelch old behavior with the police state approach, gulag energy must be consistently applied.

To squelch is one thing, but to create lasting behavior change is another altogether. But as different as they are, there’s a blurry line of justice that flips innocent to guilty. And to walk the line you’ve got to know where it is:

- Apply force, yes, but only enough to prevent backsliding – like a human ratchet. Push much harder and heels dig in.

- The only thing slower than going slow is going too fast. (Remember, you’re asking people to change the why of their behavior.) Go slow to go fast.

- Set direction and stay the course, unless there’s good reason to change. And when the team comes to you with a reason, deem it a good one, and the cornerstone of trust is laid. (This is a game of trust, not control.)

But there are some mantras to maximize:

- Over emphasize the positive and overlook the negative.

- Praise in public.

- Don’t talk, do.

The first two stand on their own, but the third deserves reinforcement.

This isn’t about your words, it’s about your behavior. And that’s good because you have full authority over your behavior. Demonstrate the new behavior so everyone knows what it looks like. Lead the way with your actions. Show them how it’s done. For lasting change, change your behavior.

Even if changing your behavior influences only one person, you’re on your way. The best prison riots start with a single punch.

Prototype the Unfamiliar

Today’s answer to everything is process and tools. Define the desired outcome; create the process; create the tools. Problem solved.

Today’s answer to everything is process and tools. Define the desired outcome; create the process; create the tools. Problem solved.

But if the desired outcome is lasting change, deterministic processes and static tools won’t get us there. Lasting change comes from people and their behavior.

Going forward, instead of creating process, create an environment of trust so people will investigate the unfamiliar; and instead of creating tools, create time – time for people to prototype the unfamiliar.

Choose to Choose

There will always be more work than time – no choice there. But, you can choose your mindset. You can choose to be overwhelmed; you can complain; and you can feel bad for yourself. You can also choose to invert it – you only work on vital projects because less important ones aren’t worth your time. Inverted, work is prioritized to make best use of your valuable time. When there’s too much work you can whine and complain, or you can value yourself – your choice

There will always be more work than time – no choice there. But, you can choose your mindset. You can choose to be overwhelmed; you can complain; and you can feel bad for yourself. You can also choose to invert it – you only work on vital projects because less important ones aren’t worth your time. Inverted, work is prioritized to make best use of your valuable time. When there’s too much work you can whine and complain, or you can value yourself – your choice

Most of us don’t choose what we work on, and sometimes it’s work we’ve done before. You can choose to look at as mind numbing tedium, or you can flip it. You can look at it as an opportunity to do your work a better way; to try a more effective approach; to invent something new. With repeat work you can dull it down or try to shine – your choice.

Sometimes we’re asked to do new and challenging work. You can choose to be afraid; you can make excuses; and you can call in sick for the next month. Or you can twist it to your advantage and see it as an opportunity to stretch. With challenging work you can stunt yourself or grow – your choice.

Negativity repels and positivity attracts – it’s time for you to choose.

Circle of Life

Engineers solve technical problems so

Other engineers can create products so

Companies can manufacture them so

They can sell them for a profit and

Use the wealth to pay workers so

Workers can support their families and pay taxes so

Their countries have wealth for good schools to

Grow the next generation of engineers to

Solve the next generation of technical problems so…

Why Tough Choices Are Tough

This week my son made a difficult choice – he chose between two things he loves.

This week my son made a difficult choice – he chose between two things he loves.

The easy choice was to say yes to both, but in reality, there was not enough time. And in reality, the easy yes was a masquerade. It was really a slow, painful no with rippling consequences to his future. The tough choice did not come immediately and it did not come easy. But in the end, he was ready to make it because he saw things not as he wanted them to be, but as they were.

Once he decided he was going to choose, he had to decide which to choose. A tough choice made tougher because one is mainstream and the other on the fringe. It was clear there were far more overt repercussions with a no to the mainstream. Simply put, the powerful mainstream would not understand. But to his credit, he recognized the mainstream cares about itself, not him. Also, it was clear the fringe accepts him for him. So he sat himself in the future, figured out what was best for the soon-to-be him, and chose the fringe.

Once he decided which to chose, he had to decide how to choose. The easy choice was to slink quietly into the fringe never to be seen again. This was another masquerade. It was really an opportunity to self-devalue his decision and a setup for never ending ridicule over the remainder of his high school career. Instead, he made the tough choice to speak truth to the mainstream authority – face-to-face.

He got up early and met the coach in his office. The gist of the meeting – I’m sad, but this is my choice and why I’m choosing.

To the coach’s great credit, though disappointed, he understood and thanked Ethan for meeting face-to-face. And though emotionally wobbly after the meeting, because he declared his choice and was validated, he stood taller. And once validated by the head of the mainstream, there was no room for ridicule.

This week my son showed me what courage is. And he taught me an important lesson – tough decisions are tough, but we’re better off for making them.

I’m proud of him.

A Race for Learning – Video Training with TED-Ed

I’ve been thinking about how to use video to train engineers. The trouble with video is it takes time and money to create. But what if you could create lessons using existing video? That’s what the new TED-Ed platform can do. With TED-Ed, any YouTube video can be “flipped” into a customized lesson.

I’ve been thinking about how to use video to train engineers. The trouble with video is it takes time and money to create. But what if you could create lessons using existing video? That’s what the new TED-Ed platform can do. With TED-Ed, any YouTube video can be “flipped” into a customized lesson.

Instead of trying to describe it, I used the new platform to create a video lesson. Click the link below and give it a try. (The platform is still in beta version, so I’m not sure how will go. But that’s how it is with experiments.)

Video lesson: Innovation, Caveman-Style

When answering the questions, it may ask you to sign up for an account. Click the X in the upper right of the message to make it go away, and keep going. If the video does not work at all, poke around the TED-Ed website.

Either way, so we can accelerate our learning and get out in front, please post a comment or two.

Celebrating Three Years of Shipulski On Design

Today is a celebration – three years of Shipulski On Design!

Today is a celebration – three years of Shipulski On Design!

I get lot’s of great feeback, but the best is when you tell me my writing touched you and helped you do your work differently. You may see this as my gift to you, but I see it as your gift to me.

Thank you for reading and commenting.

Below are some highlights for 2012:

Accomplishments in 2012

- Third year of weekly blog posts without missing a beat or repeating (203 posts in total).

- Second year of daily tweets – 1520 in all (@mikeshipulski).

- Top 40 Innovation Bloggers – Innovation Excellence, the web’s top innovation site.

- Sixth consecutive year as Keynote Speaker at International Forum on DFMA.

- Started Pinterest page – cool engineering pictures and video content – (ShipOnDesign).

- Third year of LinkedIn working group – Systematic DFMA Deployment.

- Second year writing a column for Assembly Magazine (6 columns this year).

Top 5 Posts

- Why it’s tough to decide — how to spot unmade decisions – gremlin style.

- Choose your path — the three paths explained – short and good.

- Impossible — well, almost.

- What is Design for Manufacturing and Assembly — the basics – video style.

- When It’s Time For a New Cowpath — great photo

I look forward to a great year 4.

Beyond Dead Reckoning

We’re afraid of technology development because it’s risky. And figuring out where to go is the risky part. To figure out where to go companies use several strategies: advance multiple technologies in parallel; ask the customer; or leave it to company leader’s edict. Each comes with its strengths and weaknesses.

We’re afraid of technology development because it’s risky. And figuring out where to go is the risky part. To figure out where to go companies use several strategies: advance multiple technologies in parallel; ask the customer; or leave it to company leader’s edict. Each comes with its strengths and weaknesses.

I think the best way to figure out where to go is to figure out where you are. And the best way to do that is data-driven S-curve analysis.

To collect data, look to your most recent product launches, say five, and characterize them using a goodness-to-cost ratio. (Think miles per gallon for your technology.) Then plot them chronologically and see how the goodness ratio has evolved – flat, slow growth, steep growth, or decline. The shape of the curve positions your technology within the stages of the S-curve and its location triangulated with contextual clues. You know where you are so you can figure out where to go.

Here’s what the stages feel like and what to do when you’re in them:

Stage 1: Infancy – New physics are used to deliver a known function, but it’s not ready for commercialization. This is like early days of the gasoline-electric hybrid vehicles, where the physics of internal combustion was combined with the physics of batteries. In Stage 1 the elements of the overall system are established, like when Honda developed its first generation Honda Insight and GM its EV1. Prototypes are under test, and they work okay, but not great. In Stage 1, goodness-to-cost is lower than existing technologies (and holding), but the bet is when they mature goodness-to-cost will be best on the planet.

If your previous products were Stage 4 (Maturity) or Stage 5 (Decline), your new project should be in Stage 1. If your existing project is in Stage 1, focus on commercialization. If all your previous projects were (are) in Stage 1, you should focus on commercializing one (moving to Stage 2) at the expense of starting a new one.

Stage 2: Transitional – A product is launched in the market and there is intense competition with existing technologies. In Stage 2, several versions of new technology are introduced (Prius, Prius pluggable, GM’s Volt, Nissan Leaf), and they fight it out. Goodness-to-cost is still less than existing technologies, but there’s some element of the technology that’s attractive. For electric vehicles, think emissions.

If your previous products were Stage 4 (Maturity) or Stage 5 (Decline) and your current project just transitioned from Stage 1, you’re in the right place. In Stage 2, fill gaps in functionality; increase controllability – better controls to improve battery performance; and develop support infrastructure -electric fueling stations.

Stage 3: Growth – Goodness-to-cost increases rapidly, and so do sales. (I think most important for an electric vehicle is miles per charge.)

If you’re in Stage 3, it’s time to find new applications – e.g., electric motorcycles, or shorten energy flow paths – small electric motors at the wheels.

Stage 4: Maturity – The product hits physical limits – flat miles per gallon; hits limits in resources – fossil fuels; hits economic limits – costly carbon fiber body panels to reduce weight; or there’s rapid growth in harmful factors – air pollution.

If you’re in Stage 4, in the short term add auxiliary functions – entertainment systems, mobile hotspot, heated steering wheel, heated washer fluid; or improve aesthetics – like the rise of the good looking small coupe. In the long term, start a Stage 1 project to move to new physics – hydrogen fuel cells.

Stage 5: Decline – New and more effective systems have entered their growth stage – Nissan Leaf outsells Ford pickup trucks.

If you’re in Stage 5, long ago you should have started at Stage 1 project – new physics. If you haven’t, it may be too late.

S-curve analysis guides, but doesn’t provide all the answers. That said, it’s far more powerful than rock-paper-scissors.

(This thinking was blatantly stolen from Victor Fey’s training on Advanced S-Curve Analysis. Thank you, Victor.)

More Risk, Less Consequence

WHY? To grow sales in existing markets and create sales in new markets.

WHY? To grow sales in existing markets and create sales in new markets.

WHAT? Create innovative technologies and design products with more function and less cost.

HOW? Educate the engineering engine.

This is easier said than done, because for years we’ve set one-sided expectations – new products must work and timelines must be met – and driven risk tolerance out of our engineering engine. Now it’s time to inject it back in.

The message – Our thinking must change. We must take more risk, but do it safely by reducing negative consequences of risk.

To reduce negative consequences of risk, we must learn to localize risk through the narrowest and deepest problem definition, and learn to secure the launch so it’s safe to try new things.

We must do more up-front technology work, but learn to do it far more narrowly and deeply. We must learn to hold ourselves accountable to rigorous problem definition, and we must put our best people on technology projects.

To focus creativity we must learn to set seemingly unrealistic time constraints; to focus our actions we can look to a powerful mantra – spend a little, learn a lot.

The trouble with new thinking is it takes new thinking. If you don’t have it, go get it. If you already have it, figure out why you haven’t used it.

The Pilgrimage of Change

The pilgrimage of change is hard.

The pilgrimage of change is hard.

Before we start, we must believe there’s a way to get there.

Before that, we must believe in the goodness of the destination.

Before that, we must believe there’s a destination.

Before that, we must want something different.

Before that, we must see things as they are.

Before that, we must want to understand.

Before that, we must be curious.

And to do that, we must believe in ourselves.

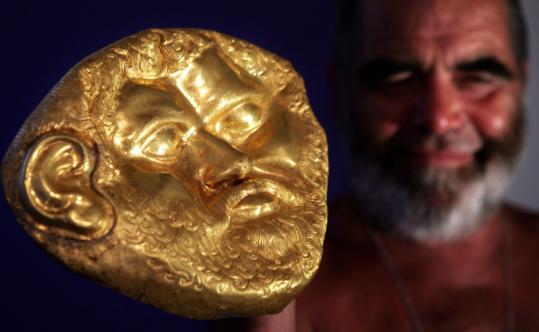

The Archeologist Technologist

Archeologists look back to see what was; they scratch the ground to find what the past left behind; then they study their bounty and speculate backward in time.

Archeologists look back to see what was; they scratch the ground to find what the past left behind; then they study their bounty and speculate backward in time.

But what makes a good archeologist? In a word – belief. Archeologists must believe there’s something out there, something under the dirt waiting for them. Sure, they use their smarts to choose the best place to dig and dig with the best tools, but they know something’s out there and have a burning desire to find it. The first rule of archeology – don’t dig, don’t find.

There’s almost direct overlap between archeologists and technologists, with one difference – where archeologists dig to define the past and technologists dig to define the future.

Technologists must use their knowledge and experience to dig in the right place and must use the best analytical digging tools. Creativity and knowledge are required to decide where to dig, and once unearthed the technologist must interpret the fragments and decide how to knit together the skeleton. But to me, the most important part of the analogy is belief – for the archeologist belief that fossils are buried under the dirt waiting to be discovered and for the technologist belief that technology is buried and waiting to be discovered.

Before powered flight, the Wright brothers believed technology was out there waiting for them. Their first flight was a monumental achievement, and I don’t want to devalue their work, but think about it – what did they create that wasn’t already there? Yes, they knit together technologies in new ways, but they didn’t create the laws of aerodynamics used for the wings (neither did the earliest aerodynamicists); they did not create the laws of thermodynamics behind the gasoline engine (neither did the early thermodynamicists who measured existing phenomena to make the laws); and they didn’t create the wood for the structure. But what they did do is dig for technology.

Space travel – for most of our history just a dream. But decades before rocket technology, it was all there waiting – the periodic table to make the fuel, the physics to make thrust, and the mechanics to create the structure. Natural resources and technologies were quilted together and processed in new ways, yes. But the technologies, or the rules to create them, were already there waiting to be discovered. And what Goddard did was dig.

The archeologist-technologist analogy can be helpful, but the notion of preexisting technology is way out there – it smacks of predestination in which I don’t believe.

But what I do believe in is belief – belief you have the capability to discover a forward-looking fossil – a future genus that others thought impossible. But only if you dig.

The first rule of technology – don’t dig, don’t find.

Mike Shipulski

Mike Shipulski