Posts Tagged ‘Creativity’

Mapping the Future with Wardley Maps

How do you know when it’s time to reinvent your product, service or business model? If you add ten units of energy and you get less in return than last time, it’s time to work in new design space. If improvement in customer goodness (e.g., miles per gallon in a car) has slowed or stopped, it’s time to seek a new fuel source. If recent patent filings are trivial enhancements that can be measured only with a large sample sizes and statistical analysis, the party is over.

How do you know when it’s time to reinvent your product, service or business model? If you add ten units of energy and you get less in return than last time, it’s time to work in new design space. If improvement in customer goodness (e.g., miles per gallon in a car) has slowed or stopped, it’s time to seek a new fuel source. If recent patent filings are trivial enhancements that can be measured only with a large sample sizes and statistical analysis, the party is over.

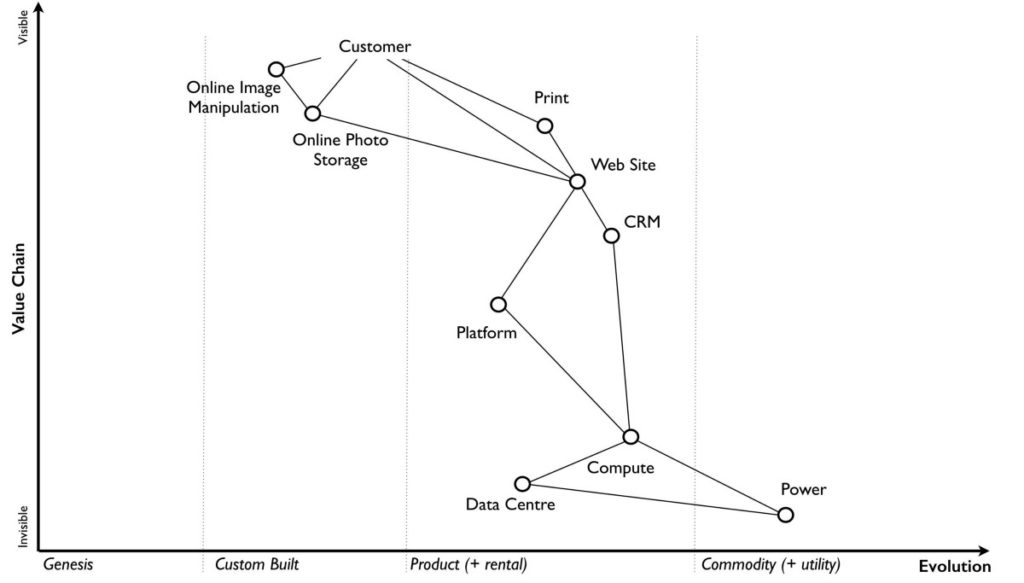

When there’s so many new things to work on, how do you choose the next project? When you’re lost, you look at a map. And when there is no map, you make one. The first bit of work is defined by the holes in the first revision of your map. And once the holes are filled and patched, the next work emerges from the map itself. And, in a self-similar way, the next work continually emerges from the previous work until the project finishes.

But with so much new territory, how do you choose the right new territory to map? You don’t. Before there’s a need to map new territory, you must map the current territory. What you’ll learn is there are immature areas that, when made mature, will deliver new value to customers. And you’ll also learn the mature areas that must be blown up and replaced with infant solutions that will ultimately create the next evolution of your business. And as you run thought experiments on your map – projecting advancements on the various elements – the right new territory will emerge. And here’s a hint – the right new solutions will be enabled by the newly matured elements of the map.

But how do you predict where the right new solutions will emerge? I can’t tell you that. You are the experts, not me. All I can say is, make the maps and you’ll know.

And when I say maps, I mean Wardely Maps – here’s a short video (go to 4:13 for the juicy bits).

Image credit – Simon Wardley

It’s time to stretch yourself.

If the work doesn’t stretch you, choose new work. Don’t go overboard and make all your work stretch you and don’t choose work that will break you. There’s a balance point somewhere between 0% and 100% stretch and that balance point is different for everyone and it changes over time. Point is, seek your balance point.

If the work doesn’t stretch you, choose new work. Don’t go overboard and make all your work stretch you and don’t choose work that will break you. There’s a balance point somewhere between 0% and 100% stretch and that balance point is different for everyone and it changes over time. Point is, seek your balance point.

To find the right balance point, start with an assessment of your stretch level. List the number of projects you have and sum the number of major deliverables you’ve got to deliver. If you have more than three projects, you have too many. And if you think you take on more than three because you’re superhuman, you’re wrong. The data is clear – multitasking is a fallacy. If you have four projects you have too many. And it’s the same with three, but you’d think I was crazy if I suggested you limit your projects to two. The right balance point starts with reducing the number of projects you work on.

Now that you eliminated four or five projects and narrowed the portfolio down to the vital two or three, it’s time to list your major deliverables. Take a piece of paper and write them in a column down the left side of the page. And in a column next to the projects, categorize each of them as: -1 (done it before), 0 (done something similar), 1 (new to me), 2 (new to team), 3 (new to company), 5 (new to industry), 11 (new to world).

For the -1s, teach an entry level person how to do it and make sure they do it well. For the 0s, find someone who deserves a growth opportunity and let them have the work. And check in with them to make sure they do a good job. The idea is to free yourself for the stretch work.

For the 1s, find the best person in the team who has done it before and ask them how to do it. Then, do as they suggest but build on their work and take it to the next level.

For the 2s, find the best person in the company who has done it before and ask them how to do it. Then, build on their approach and make it your own.

For the 3s, do your research and find out who in your industry has done it before. Figure out how they did it and improve on their work.

For the 5s, do your research and figure out who has done similar work in another industry. Adapt their work to your application and twist it into something magical.

And for the 11s, they’re a special project category that live in rarified air and deserve a separate blog post of their own.

Start with where you are – evaluate your existing deliverables, cull them to a reasonable workload and assess your level of stretch. And, where it makes sense, stop doing work you’ve done before and start doing work you haven’t done yet. Stretch yourself, but be reasonable. It’s better to take one bite and swallow than take three and choke.

Image credit – filtran

The Evolution of New Ideas

Before there is something new to see, there is just a good idea worthy of a prototype. And before there can be good ideas there are a whole flock of bad ones. And until you have enough self confidence to have bad ideas, there is only the status quo. Creating something from nothing is difficult.

Before there is something new to see, there is just a good idea worthy of a prototype. And before there can be good ideas there are a whole flock of bad ones. And until you have enough self confidence to have bad ideas, there is only the status quo. Creating something from nothing is difficult.

New things are new because they are different than the status quo. And if the status quo is one thing, it’s ruthless in desire to squelch the competition. In that way, new ideas will get trampled simply based on their newness. But also in that way, if your idea gets trampled it’s because the status quo noticed it and was threatened by it. Don’t look at the trampling as a bad sign, look at it as a sign you are on the right track. With new ideas there’s no such thing as bad publicity.

The eureka moment is a lie. New ideas reveal themselves slowly, even to the person with the idea. They start as an old problem or, better yet, as a successful yet tired solution. The new idea takes its first form when frustration overcomes intellectual inertia a strange sketch emerges on the whiteboard. It’s not yet a good idea, rather it’s something that doesn’t make sense or doesn’t quite fit.

The idea can mull around as a precursor for quite a while. Sometimes the idea makes an evolutionary jump in a direction that’s not quite right only to slither back to it’s unfertilized state. But as the environment changes around it, the idea jumps on the back of the new context with the hope of evolving itself into something intriguing. Sometimes it jumps the divide and sometimes it slithers back to a lower energy state. All this happens without conscious knowledge of the inventor.

It’s only after several mutations does the idea find enough strength to make its way into a prototype. And now as a prototype, repeats the whole process of seeking out evolutionary paths with the hope of evolving into a product or service that provides customer value. And again, it climbs and scratches up the evolutionary ladder to its most viable embodiment.

Creating something new from scratch is difficult. But, you are not alone. New ideas have a life force of their own and they want to come into being. Believe in yourself and believe in your ideas. Not every idea will be successful, but the only way to guarantee failure is to block yourself from nurturing ideas that threaten the status quo.

Image credit – lost places

Make It Easy

When you push, you make it easy for people resist. When you break trail, you make it easy for them to follow.

When you push, you make it easy for people resist. When you break trail, you make it easy for them to follow.

Efficiency is overrated, especially when it interferes with effectiveness. Make it easy for effectiveness to carry the day.

You can push people off a cliff or build them a bridge to the other side. Hint – the bridge makes it easy.

Even new work is easy when people have their own reasons for doing it.

Making things easier is not easy.

Don’t tell people what to do. Make it easy for them to use their good judgement.

Set the wrong causes and conditions and creativity screeches to a halt. Set the right ones and it flows easily. Creativity is a result.

Don’t demand that people pull harder, make it easier for them to pull in the same direction.

Activity is easy to demonstrate and progress isn’t. Figure out how to make progress easier to demonstrate.

The only way to make things easier is to try to make them easier.

Image credit – Richard Hurd

The Power of Surprise

There’s disagreement on what is creative, innovative and disruptive. And there is no set of hard criteria to sort concepts into the three categories. Stepping back a bit, a lesser but still important sorting is an in-or-out categorization. Though not as good as discerning among the three, it is useful to decide if a new concept is in (one of the three) or out (not).

There’s disagreement on what is creative, innovative and disruptive. And there is no set of hard criteria to sort concepts into the three categories. Stepping back a bit, a lesser but still important sorting is an in-or-out categorization. Though not as good as discerning among the three, it is useful to decide if a new concept is in (one of the three) or out (not).

The closest thing to an acid test is assessment of the emotional response generated by a new concept. Here are some responses that I consider tell-tail signs of powerful ideas/concepts worthy of the descriptors creative, innovative, or disruptive.

When first shown, a prototype creates fear and defensiveness. The fear signals that the prototype threatens the status quo and defensiveness is objective evidence of the fear.

When first explained, a new concept creates anger and aggression. Because the concept doesn’t play by the rules, it disrespects everything holy, and the unfairness spawns indigence.

After some time, the dismissive comments about the new prototype fade and turn to discussions colored by deep sadness as the gravity of the situation hits home.

But the best leading indicator is surprise. When a test result doesn’t match your expectations, it generates surprise. And since your expectations are built on your mental models, surprising concepts contradict your mental models. And since your mental models are formed by successful experiences, prototypes that create surprise violate previous success.

If you’re surprised by a new concept, it’s worth a deeper look. If you’re not surprised, move on.

If you’re not tolerant of surprise, you should be. And if you are tolerant of surprise, it’s time to become fervent.

Image credit – Raul Pop

How to wallow in the mud of uncertainty.

Creativity and innovation are dominated by uncertainty. And in the domain of uncertainty, not only are the solutions unknown, the problems are unknown. And yet, we still try to use the tried-and-true toolbox of certainty even after it’s abundantly clear those wrenches don’t fit.

Creativity and innovation are dominated by uncertainty. And in the domain of uncertainty, not only are the solutions unknown, the problems are unknown. And yet, we still try to use the tried-and-true toolbox of certainty even after it’s abundantly clear those wrenches don’t fit.

When wallowing in the mud of uncertainty and company leaders ask, “When will you be done?”, the only real answer is a description of the next thing you’ll try to learn. “We will learn if Step 1 is possible.” And then the predicted response, “Well, when will you be done with that?” The only valid response is, “It depends.” Though truthful, this goes over like a lead balloon. And the dialog continues – “Okay, then, what is Step 2?” The unpalatable answer, “It depends. If Step 1 is successful, we’ll move onto Step 2, but if Step 1 is unsuccessful, we’ll step back and regroup.” This, too, though truthful, is unsatisfactory.

When doing creative work, there’s immense pressure to be done on time. But, that pressure is inappropriate. Yes, there can be pressure to learn quickly and effectively, but the expectation to be done within an arbitrary timeline is ludicrous. Managers don’t know this, but when they demand a completion date for a task that has never been done before, the people doing the creative work know the manager doesn’t know what they’re doing. They won’t tell the manager what they think, but they definitely think it. And when pushed to give a completion date, they’ll give one, knowing full well the predicted date is just as arbitrary as the manager’s desired timeline.

But learning objectives can create common ground. Starting with “We want to learn if…”, learning objectives define what the project team must learn. Though there’s no agreement on when things will be completed, everyone can agree on the learning objectives. And with clearly defined learning objectives and measurable definitions of success, the project can move forward with consensus. There is still consternation over the lack of hard deadlines for the learning objectives, but there is agreement on the sequence of events, tests protocols or analyses that will be carried out to learn what must be learned.

Two rules to live by: If you know when you’ll be done, you’re not doing innovation. And if no one is surprised by the solution, you’re not doing creative work.

Image credit – Michael Carian

Innovation in three words – Solve Different Problems

With innovation, novel solutions pay the bills – a new solution provides new value for the customer and the customer buys it from you. The trick, however, is to come up with novel solutions. To improve the rate and quality of novel solutions, there’s usually a focus on new tools, new problem-solving methods and training on both. The idea is get better at moving from problem to solution. There’s certainly room for improvement in our problem-solving skills, but I think the pot of gold is hidden elsewhere.

With innovation, novel solutions pay the bills – a new solution provides new value for the customer and the customer buys it from you. The trick, however, is to come up with novel solutions. To improve the rate and quality of novel solutions, there’s usually a focus on new tools, new problem-solving methods and training on both. The idea is get better at moving from problem to solution. There’s certainly room for improvement in our problem-solving skills, but I think the pot of gold is hidden elsewhere.

Because novel solutions reside in uncharted design space, it follows that novel solutions will occur more frequently if the problem-solvers are pointed toward new design space. And to make sure they don’t solve in the tired, old design space of success, constraints are used to wall it off. Rule 1 – point the solvers toward new design space. Rule 2 – wall off the over-planted soil of success.

The best way to guide the problems solvers toward fertile design space is to create different problems for them to solve. And this guide-the-solvers thinking is a key to the success of the IBE (Innovation Burst Event), where Design Challenges are created in a way that forces the solvers from the familiar. And it’s these Design Challenges that ARE the new problems that bring the new solutions. And to wall off old design space, the Design Challenges use creatively curated constraints to make it abundantly clear that old solutions won’t cut it.

Before improving the back-end problem solving process, why not change the front- end problem selecting process?

Chose to solve different problems, then learn to solve them differently.

Image credit – Rajarshi MITRA

The Additive Manufacturing Maturity Model

Additive Manufacturing (AM) is technology/product space with ever-increasing performance and an ever-increasing collection of products. There are many different physical principles used to add material and there are a range of part sizes that can be made ranging from micrometers to tens of meters. And there is an ever-increasing collection of materials that can be deposited from water soluble plastics to exotic metals to specialty ceramics.

Additive Manufacturing (AM) is technology/product space with ever-increasing performance and an ever-increasing collection of products. There are many different physical principles used to add material and there are a range of part sizes that can be made ranging from micrometers to tens of meters. And there is an ever-increasing collection of materials that can be deposited from water soluble plastics to exotic metals to specialty ceramics.

But AM tools and technologies don’t deliver value on their own. In order to deliver value, companies must deploy AM to solve problems and implement solutions. But where to start? What to do next? And how do you know when you’ve arrived?

To help with your AM journey, below a maturity model for AM. There are eight categories, each with descriptions of increasing levels of maturity. To start, baseline your company in the eight categories and then, once positioned, look to the higher levels of maturity for suggestions on how to move forward.

For a more refined calibration, a formal on-site assessment is available as well as a facilitated process to create and deploy an AM build-out plan. For information on on-site assessment and AM deployment, send me a note at mike@shipulski.com.

Execution

- Specify AM machine – There a many types of AM machines. Learn to choose the right machine.

- Justify AM machine – Define the problem to be solved and the benefit of solving it.

- Budget for AM machine – Find a budget and create a line item.

- Pay for machine – Choose the supplier and payment method – buy it, rent to own, credit card.

- Install machine – Choose location, provide necessary inputs and connectivity

- Create shapes/add material – Choose the right CAD system for the job, make the parts.

- Create support/service systems – Administer the job queue, change the consumables, maintenance.

- Security – Create a system for CAD files and part files to move securely throughout the organization.

- Standardize – Once the first machines are installed, converge on a small set of standard machines.

- Teach/Train – Create training material for running AM machine and creating shapes.

Solution

- Copy/Replace – Download a shape from the web and make a copy or replace a broken part.

- Adapt/Improve – Add a new feature or function, change color, improve performance.

- Create/Learn – Create something new, show your team, show your customers.

- Sell Products/Services – Sell high volume AM-produced products for a profit. (Stretch goal.)

Volume

- Make one part – Make one part and be done with it.

- Make five parts – Make a small number of parts and learn support material is a challenge.

- Make fifty parts – Make more than a handful of parts. Filament runs out, machines clog and jam.

- Make parts with a complete manufacturing system – This topic deserves a post all its own.

Complexity

- Make a single piece – Make one part.

- Make a multi-part assembly – Make multiple parts and fasten them together.

- Make a building block assembly – Make blocks that join to form an assembly larger than the build area.

- Consolidate – Redesign an assembly to consolidate multiple parts into fewer.

- Simplify – Redesign the consolidated assembly to eliminate features and simplify it.

Material

- Plastic – Low temperature plastic, multicolor plastics, high performance plastics.

- Metal – Low melting temperature with low conductivity, higher melting temps, higher conductivity

- Ceramics – common materials with standard binders, crazy materials with crazy binders.

- Hybrid – multiple types of plastics in a single part, multiple metals in one part, custom metal alloy.

- Incompatible materials – Think oil and water.

Scale

- 50 mm – Not too large and not too small. Fits the build area of medium-sized machine.

- 500 mm – Larger than the build area of medium-sized machine.

- 5 m – Requires a large machine or joining multiple parts in a building block way.

- 0.5 mm – Tiny parts, tiny machines, superior motion control and material control.

Organizational Breadth

- Individuals – Early adopters operate in isolation.

- Teams – Teams of early adopters gang together and spread the word.

- Functions – Functional groups band together to advance their trade.

- Supply Chain – Suppliers and customers work together to solve joint problems.

- Business Units – Whole business units spread AM throughout the body of their work.

- Company – Whole company adopts AM and deploys it broadly.

Strategic Importance

- Novelty – Early adopters think it’s cool and learn what AM can do.

- Point Solution – AM solves an important problem.

- Speed – AM speeds up the work.

- Profitability – AM improves profitability.

- Initiative – AM becomes an initiative and benefits are broadly multiplied.

- Competitive Advantage – AM generates growth and delivers on Vital Business Objectives (VBOs).

Image credit – Cheryl

Leadership isn’t binary, and that’s why judgement is important.

100% of the people won’t like your new idea, even if it’s a really good one like the airplane, mayonnaise or air conditioning.

100% of the people won’t like your new idea, even if it’s a really good one like the airplane, mayonnaise or air conditioning.

I don’t know the right amount of conflict, but I know it’s not 0% or 100%.

If 100% is good, 110% isn’t better. Percentages don’t work that way.

100% alignment is not the best thing. Great things aren’t built on the back of consensus.

100% of the problems shouldn’t be solved. Sometimes it’s best to let the problem blossom into something that cannot be dismissed, denied or avoided.

Fitting in can be good, but not 100% of the time. Sometimes the people in power need to hear the truth, even if you know they’ll choke on it.

If the system is in the way, work the rule. Follow it 100%, follow it to the letter, follow it until it’s absurd. But, keep in mind the system isn’t in the way 100% of the time.

Following the process 100% eliminates intellectual diversity. And, as Darwin said, that leads to extinction. I think he was onto something.

Trying to fix 100% of the problems leads to dilution. Solve one at a time until you’re done.

The best tool isn’t best 100% of the time. Here’s a rule: If the work’s new, try a new tool. You can’t cut a board with a hammer.

I don’t know how frequently to make mistakes, but I know it’s not 0% or 100% of the time.

As a sport, leadership isn’t binary. That’s why we’re paid to use our good judgement.

Image credit – Joe Dyer

The Three Rs of Innovation – Risk, Reward, and Resources

Is it innovation or continuous improvement or is it innovation? Is it regular innovation or disruptive innovation? Is it new enough or too new? These questions are worse than meaningless as they suck emotional energy from the organization and divert emotional energy from the business objective.

Is it innovation or continuous improvement or is it innovation? Is it regular innovation or disruptive innovation? Is it new enough or too new? These questions are worse than meaningless as they suck emotional energy from the organization and divert emotional energy from the business objective.

With every initiative, there are risks, rewards, and resources. Risk generally tracks with newness, reward usually tracks with incremental customer goodness and resources are governed by the work. Risk is about the probability of tackling the newness, reward is about the size of the prize and resources are about how the work is done. There is no best amount of risk as sometimes the right amount is none and other times it’s more than everyone prefers. And there’s no best amount of reward as it depends on the company’s goals. And there’s no right amount of resources because there’s no right scope. For all three – risk, reward and resources – the right amount depends on the context.

For bottom line projects, it’s about maintaining product functionality while eliminating waste. And while there’s no right amount of risk, reward and resources, three filters (people, process, tools) can help get everyone on the same page.

Here are the escalating categories for people – no new people, move people from group A to group B, hire more people like the ones we have, hire new people with skills we don’t have. And for categories for process – no new processes, eliminate steps of existing processes, add steps to existing processes, create a process that’s new to the facility, create a process that’s new to the company, create process that’s new to the industry, create a process that’s new to the world. And for tools – no new tools, modify existing tools, buy new tools, create new tools from scratch.

There are no right answers, but if you’ve got to hire people you’ve never hired, create processes that are new-to-world, and invent new tools, it’s clear to everyone the project is pushing the envelope. And if the reward is significant and resources are plentiful, it could be a good way to go. And if there are no new hires, no new processes, and no new tools, don’t expect extravagant rewards. It’s not an exact science, but categorizing the newness in people, process, and tools and then comparing with the reward (payoff) makes clear any mismatches. And when mismatches are clear they can be managed. Resources can be added, the scope can be reduced and reward can be revisited.

For top line projects, it’s about providing novel usefulness to customers at a reasonable cost. And while risk, reward, and resources must be balanced, the filters are different. For top line, the filters are breadth of applicability, competition, is/isn’t.

Here are the escalating categories for breadth of applicability – same customer in the same application, same customers in a new application, new customers in a new market, new customers in different industry, new customers in an industry created by the project. For competition – many competitors in the same industry, fewer competitors in the same industry, fewer competitors in a different industry, no competitors (compete with no one.) And for is/isn’t – improve what is, radically improve what is, create what isn’t.

Again, no right answers. But the plan is to sell to the same customers into markets with the same powerful competitors with only a slight improvement to the existing product, don’t expect radical rewards and don’t run a project that consumes significant resources. And, if the plan is to create a whole new industry where there are no competitors and it requires an entirely new service that doesn’t yet exist, the potential reward should be spectacular, expect to allocate a boatload of resources and prepare for the project to take longer than expected or to be cancelled before completion.

Balancing risk, reward and resources is not an exact science. And the only way to get good at it is to calibrate new projects based on previous projects. To start the calibration process, try the process on your most recent completed projects. Categorize the projects with the relevant filters and define the resources consumed and the realized rewards. And when planning the next project, categorize with the filters and define the resource plan and planned rewards and see how they compare with the completed projects. And if there are mismatches, reconcile them with the realities of the previous projects.

Image credit – Ian Sane

Innovate like a professional with the Discovery Burst Event.

Recreational athletes train because they enjoy the activity and they compete so they can tell themselves (and their friends) stories about the race. Their training routines are discretionary and their finish times are all about bragging rights. Professional athletes train because it’s their job. Their training is unpleasant, stressful and ritualistic. And it’s not optional. And their performance defines their livelihood. A slow finish time negatively impacts their career. With innovation, you have a choice – do you want to do it like a recreational athlete or like a professional? Do you want to do it like it’s discretionary or like your livelihood depends on it?

Recreational athletes train because they enjoy the activity and they compete so they can tell themselves (and their friends) stories about the race. Their training routines are discretionary and their finish times are all about bragging rights. Professional athletes train because it’s their job. Their training is unpleasant, stressful and ritualistic. And it’s not optional. And their performance defines their livelihood. A slow finish time negatively impacts their career. With innovation, you have a choice – do you want to do it like a recreational athlete or like a professional? Do you want to do it like it’s discretionary or like your livelihood depends on it?

Like with the professional athlete, with innovation what worked last time is no longer good enough. Innovation demands we perform outside our comfort zone.

Goals/Objectives are the key to performing out of our comfort zone. And to bust through intellectual inertia, one of the most common business objectives is a goal to grow revenue. “Grow the top line” is the motto of the professional innovator.

To deliver on performance goals, coaches give Strategic Guidance to the professional athlete, and it’s the same for company leaders – it’s their responsibility to guide the innovation approach. The innovation teams must know if their work should focus on a new business model, a new service or a new product. And to increase the bang for the buck, an Industry-First approach is recommended, where creation of new customer value is focused within a single industry. This narrows the scope and tightens up the work. The idea is to solve a problem for an industry and sell to the whole of it. And to tighten things more, a Flagship Customer is defined with whom a direct partnership can be developed. Two attributes of a Flagship Customer – big enough to create significant sales growth and powerful enough to pull the industry in its wake.

It’s the responsibility of the sales team to identify the Flagship Customer and broker the first meeting. At the meeting, a Customer-Forward approach is proposed, where a diverse team visits the customer and dives into the details of their Goals/Objectives, their work and their problems. The objective is to discover new customer outcomes and create a plan to satisfy them. The Discovery Burst Event (DBE) is the mechanism to do the work It’s a week-long event where marketing, sales, engineering, manufacturing and technical services perform structured interviews to get to the root of the customer’s problems AND, in a Go-To-The-Work way, walk their processes and use their eyeballs to discover solutions to problems the customer didn’t know they had. The DBE culminates with a report out to leaders of the Flagship Company where new customer outcome statements are defined along with a plan to assess the opportunities (impact/effort) and come back with proposals to satisfy the most important outcome statements.

After the DBE, the team returns home and evaluates and prioritizes the opportunities. As soon as possible, the prioritization decisions are presented to the Flagship Customer along with project plans to create novel solutions. In a tactical sense, there are new opportunities to sell existing products and services. And in a strategic sense, there are opportunities to create new business models, new services and new products to reinvent the industry.

In the short term, sales of existing products increase radically. And in the longer term, where new solutions must be created, the Innovation Burst Event (IBE) process is used to quickly create new concepts and review them with the customer in a timely way. And because the new concepts solve validated customer problems, by definition the new concepts will be valued by the customer. In a Customer-Forward way, the new concepts created by the IBE are driven by the customer’s business objectives and their problems.

This Full Circle approach to innovation pushes everyone out of their comfort zones to help them become professional innovators. Company leadership must stick out their necks and give strategic guidance, sales teams must move to a trusted advisor role, engineering and marketing teams must learn to listen to (and value) the customer’s perspective, and new ways of working – the Discovery Burst Event (DBE) and Innovation Burst Event (IBE) – must be embraced. But that’s what it takes to become professional innovators.

Innovation isn’t a recreational sport, and it’s time to behave that way.

Image credit – Lwp Kommunikáció

Mike Shipulski

Mike Shipulski