Archive for the ‘How To’ Category

When Your Plans Must Change….

To do new things, you’ve got to stop old things.

To do new things, you’ve got to stop old things.

If you don’t stop old things, you can’t start new things.

Resources limit the work that can be done.

If you have more work than resources, you won’t be able to complete everything.

Spread your resources across fewer projects, and you’ll accomplish more.

If you run more projects, you’ll get fewer done. Resource density matters.

For new behavior to start, old behavior must stop.

If you don’t stop old behavior, you can’t start new behavior.

When your standard work no longer works, it becomes non-standard work.

When it’s time for new work, non-standard work becomes standard work.

To get more done, improve efficiency.

To get the right work done, improve effectiveness.

New behavior requires a forcing function.

No forcing function, no change.

Things change at the speed of trust.

No trust, no change.

Transformational change isn’t a thing.

Evolutionary change is a thing.

Starting new projects is easy.

Finishing new projects requires stopping/finishing old ones, which is difficult.

Creating a start-doing list is common.

Creating a stop-doing list is unheard of.

Image credit — Demetri Dourambeis

Solving The Wrong Problem

The CEO doesn’t decide if it’s good enough. The VP of Marketing doesn’t decide if it’s good enough. The VP of Engineering doesn’t decide if it’s good enough. The customer decides if it’s good enough.

The CEO doesn’t decide if it’s good enough. The VP of Marketing doesn’t decide if it’s good enough. The VP of Engineering doesn’t decide if it’s good enough. The customer decides if it’s good enough.

If the product isn’t selling, the price may be okay, but the performance may not be good. In this case, it’s time to add some sizzle. And who decides if the sizzle is sufficient? You guessed it – the customer. And if you add the sizzle and they buy more, the sizzle was the problem. If they don’t buy more, it wasn’t the sizzle.

If the product isn’t selling, the performance may be okay, but the price may be too high. In this case, it’s time to pull some cost out of the product and reduce the price. Maybe a better way is to test a lower price with customers. If they buy more, it’s worth doing the work to pull out the cost. If they don’t buy at the lower price, the price isn’t the problem. You still have some work to do.

If the product isn’t selling, both the performance and the price may be the problem. It’s time to add some sizzle and lower the price. But there’s no need to do the work until you test the hypothesis. Make a one-page sales tool with the new sizzle and price. If they like it, make it so. If they don’t like it, make another sales tool with some different sizzle and a different price. Repeat the process until the customer likes the new offering. Then, make it so.

If the product isn’t selling, it’s possible the sales channel isn’t making enough money when they sell your product. To test this, go on several sales calls with them. If they are unwilling to bring you on the sales calls, it’s a good sign that there’s not enough money in it for them. There are three ways to move forward. Reduce the price to the channel partner. If they sell more, you’re off to the races if, of course, there is enough margin in the product to support the reduced price. Make it easier for them to sell your product so they spend less time and effort and make more profit. Sell through a different channel.

When your product isn’t selling, figure out why it isn’t selling. And because there are many possible reasons your product isn’t selling, it’s best to create a hypothesis and test it. Your job is not to solve the problem; rather, your job is to figure out what the problem is and to decide whether it’s worth solving.

If you create a one-page sales tool with a lower price and customers still don’t want to buy it, don’t bother to design out the cost or reduce the price. If you create a one-page sales tool with a new DVP and the customers still don’t want to buy it, don’t do the work to develop that new DVP. If you test a reduced price to the channel and they sell a few more systems, don’t reduce the price because it’s not worth it.

Once you have objective evidence that you know what the problem is and it’s worth solving, do the work to solve it and implement the solution. If you don’t have objective evidence that you know what the problem is, it’s not yet time to solve it.

There’s nothing worse than solving the wrong problem. And the customer decides if the problem is worth solving.

Image credit — Geoff Henson

Degrees of Not Knowing

You know you know, but you don’t.

You know you know, but you don’t.

You think you know, but you don’t.

You’re pretty sure you don’t know.

You know you don’t know, you think it’s not a problem that you don’t, but it is a problem.

You know you don’t know, you think it’s a problem that you don’t, but it isn’t a problem.

You don’t know, you don’t know that you don’t need to know yet, and you try.

You don’t know, you know you don’t need to know yet, and you wait.

You don’t know, you can’t know, you don’t know you can’t, and you try.

You don’t know, you can’t know, you know you can’t, and you wait.

Some skills you may want to develop….

To know when you know and when you don’t, ask yourself if you know and listen to the response.

To know if it’s a problem that you don’t know or if it isn’t, ask yourself, “Is it a problem that I don’t know?” If it isn’t, let it go. If it is, get after it.

To know if it’s not time to know or if it is, ask yourself, “Do I have to know this right now?” If it’s not time, wait. If it is time, let the learning begin. Trying to know before you need to is a big waste of time.

To know if you can’t know or if you can, ask yourself, “Can I know this?” and listen for the answer. Trying to learn when you can’t is the biggest waste of time.

Image credit — Dennis Skley

Seeing Growth A Different Way

Growing a company is challenging. Here are some common difficulties and associated approaches to improve effectiveness.

Growing a company is challenging. Here are some common difficulties and associated approaches to improve effectiveness.

No – The way we work is artisanal.

Yes – We know how to do the work innately.

It’s perfectly fine if the knowledge lives in the people.

Would you rather the knowledge resides in the people, or not know at all?

You know how to do the work. Celebrate that.

No – We don’t know how to scale.

Yes – We know how to do the work, and that’s the most difficult part.

It doesn’t make sense to scale before you’ve done it for the first time.

Socks then shoes, not shoes then socks.

If you can’t do it once, you can’t scale it. That’s a rule.

Give yourselves a break. You can learn how to scale it up.

No – We don’t know how to create the right organizational structure.

Yes – We get the work done, despite our informal structure.

Your team grew up together, and they know how to work together.

Imagine how good you’ll be with a little organizational structure!

There is no “right” organizational structure. Add what you need where you need it.

Don’t be so hard on yourselves. Remember, you’re getting the work done.

No – We don’t have formal production lines.

Yes – Our volumes are such that it’s best to keep the machines in functional clusters.

It’s not time for you to have production lines. You’re doing it right.

When production volume increases, it will be time for production lines.

Go get the business so you can justify the production lines.

No – We have too many projects. It was easier when we had a couple of small projects.

Yes – We have a ton of projects that could take off!

Celebrate the upside. This is what growth feels like.

When the projects hit big, you’ll have the cash for the people and resources you need.

Would you rather the projects take off or fall flat?

Be afraid, celebrate the upside, and go get the projects.

No – We need everything.

Yes – Our people, processes, and systems are young AND we’re getting it done!

Assess the work, define what you need, take the right first bite, and see how it goes.

Reassess the work, define the next right bite, put it in place, and see how it goes.

Repeat.

This is The Way.

Attitude matters. Language matters. Approach matters. People matter.

Image credit — Eric Huybrechts (Temple of Janus)

How To Put The Business Universe On One Page

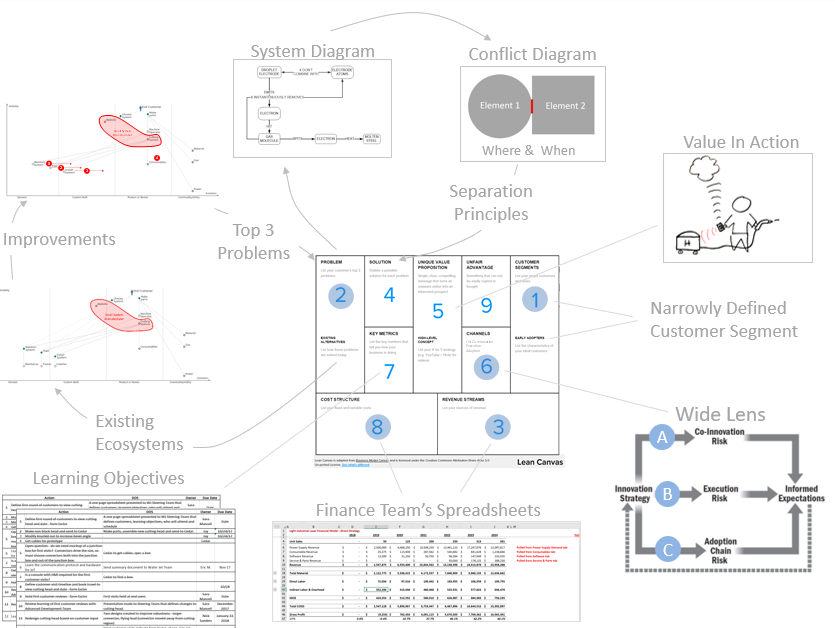

When I want to understand a large system, I make a map. If the system is an ecosystem, I combine Wardley Maps by Simon Wardley with Wide Lens / Winning The Right Game by Ron Adner. On Wardley maps, activities and actors are placed on the map, and related elements are connected. On the left are infant and underdeveloped elements, and on the right are fully developed / commodity elements. It’s like an S-curve that’s been squished flat.

When I want to understand a large system, I make a map. If the system is an ecosystem, I combine Wardley Maps by Simon Wardley with Wide Lens / Winning The Right Game by Ron Adner. On Wardley maps, activities and actors are placed on the map, and related elements are connected. On the left are infant and underdeveloped elements, and on the right are fully developed / commodity elements. It’s like an S-curve that’s been squished flat.

Wide Lens prompts you to consider co-innovation (who needs to innovate for you to be successful) and adoption (who needs to believe your idea is a good one). Winning The Right Game makes you think through the sequence of attracting partners like a visual time-lapse of the ecosystem’s evolution. This is a killer combination that demands you put the whole system on one page – all the players/partners, all the activities sorted by maturity, all the interactions, and the evolution of the partner network and maturity of the system elements. This forces a common understanding of the ecosystem. There’s no way out. Did I say it must fit on one page?

When the large system is a technological system, I make a map. I use the best TRIZ book (Innovation On Demand) by Victor Fey. A functional analysis is performed on the system using noun-verb pairs that are strung together to represent how the system behaves. If you want to drive people crazy, this is the process for you. It requires precise words for each noun (element) and verb (action) pair, and the pairs must hang together in a way that represents the physical system. There can be only one description of the system, and the fun and games don’t stop until the team converges on a single representation of the system. It’s all good fun until someone loses an eye.

When I want to understand a business/technology/product/service offering that has not been done before (think startup), I use Lean Canvas by Ash Maurya. The Lean Canvas requires you to think through all elements of the system and forces you to put it on one page. (Do you see a theme here?) Value proposition, existing alternatives, channel to market, customer segments, metrics, revenue, costs, problems, and solutions – all of them on one page.

And then to blow people’s minds, I combine Wardley Maps, Wide Lens, Winning The Right Game, functional analysis of TRIZ, value in action, and Lean Canvas on one page. And this is what it looks like.

Ash’s Lean Canvas is the backplane. Ron’s Wide Lens supports 6 (Channel), forcing a broader look than a traditional channel view. Ron’s Winning The Right Game and Simon’s Wardley Map are smashed together to support 2 (Existing Alternatives/Problems). A map is created for the existing system with system elements (infants on the left, retirees on the right) and partners/players, which are signified by color (red blob). Then, a second map is created to define the improvements to be made (red circles with arrows toward a more mature state). Victor’s Functional Analysis/System diagram defines the problematic system, and TRIZ tools, e.g., Separation Principles, are used to solve the problem.

When I want to understand a system (ecosystem or technological system), I make a map. And when I want to make a good map, I put it on one page. And when I want to create a new technological system that’s nested in a new business model that’s nested in a new ecosystem, I force myself to put the whole universe on one page.

Image credit – Giuseppe Zeta

Good Teachers Are Better Than Good

Good teachers change your life. They know what you know and bring you along at a pace that’s right for you, not too slowly that you’re bored and not too quickly that your head spins. And everything they do is about you and your learning. Good teachers prioritize your learning above all else.

Good teachers change your life. They know what you know and bring you along at a pace that’s right for you, not too slowly that you’re bored and not too quickly that your head spins. And everything they do is about you and your learning. Good teachers prioritize your learning above all else.

Chris Brown taught me Axiomatic Design. He helped me understand that design is more than what a product does. All meetings and discussions with Chris started with the three spaces – Functional Requirements (FRs) what it does, Design Parameters (DPs) what it looks like, and Process Variables (PVs) how to make it. This was the deepest learning of my professional life. To this day, I am colored by it. And the second thing he taught me was how to recognize functional coupling. If you change one input to the design and two outputs change, that’s functional coupling. You can manage functional coupling if you can see it. But if you can’t see it, you’re hosed. Absolutely hosed.

Vicor Fey taught me TRIZ. He helped me understand the staggering power of words to limit and shape our thinking. I will always remember when he passionately expressed in his wonderful accent, “I hate words!” And to this day, I draw pictures of problems and I avoid words. And the second thing he taught me is that a problem always exists between two things, and those things must touch each other. I make people’s lives miserable by asking – Can you draw me a picture of the problem? And, Which two system elements have the problem, and do they touch each other? And the third thing he taught me was to define problems (Yes, Victor, I know I should say conflicts.) in time. This is amazingly powerful. I ask – “Do you want to solve the problem before it happens, while it happens, or after it happens?” Defining the problem in time is magically informative.

Don Clausing taught me Robust Design. He helped me understand that you can’t pass a robustness test. He said, “If you don’t break it, you don’t know how good it is.” He was an ornery old codger, but he was right. Most tests are stopped before the product fails, and that’s wrong. He also said, “You’ve got to test the old design if you want to know if the new one is better.” To this day, I press for A/B testing, where the old design and new design are tested against the same test protocol. This is much harder than it sounds and much more powerful. He taught me to test designs at stress levels higher than the operating stresses. He said, “Test it, break it, and improve it. And when you run out of time, launch it.” And, lastly, he said, “Improve robustness at the expense of predicting it.” He gave zero value to statistics that predict robustness and 100% value to failure mode-based testing of the old design versus the new one.

The people I work with don’t know Chris, Victor, or Don. But they know the principles I learned from them. I’m a taskmaster when it comes to FRs-DPs-PVs. Designs must work well, be clearly defined by a drawing, and be easy to make. And people know there’s no place in my life for functional coupling. My coworkers know to draw a picture of the problem, and it better be done on one page. And they know the problem must be shown to exist between two things that touch. And they know they’ll get the business from me if they don’t declare that they’re solving it before, during, or after. They know that all new designs must have A/B test results, and the new one must work better than the old one. No exceptions.

I am thankful for my teachers. And I am proud to pass on what they gave me.

Image credit — Christof Timmermann

Fight Dilution!

With new product development projects, there is no partial credit. If you’re less than 100% done, there are zero sales. 90% done, zero sales. 95% done, zero sales. We all understand the concept, but our behavior often contradicts our understanding. You have too many projects, and our focus on efficiency is to blame.

With new product development projects, there is no partial credit. If you’re less than 100% done, there are zero sales. 90% done, zero sales. 95% done, zero sales. We all understand the concept, but our behavior often contradicts our understanding. You have too many projects, and our focus on efficiency is to blame.

Under the banner of efficiency, we run too many projects in parallel, and our limited resources become spread too thinly over too many projects. Project timelines grow, launch dates are pushed out, and revenue generation is delayed. And because there’s a shortfall in revenue, we start more projects to close the gap. That’s funny.

In short, we’ve morphed Start, Stop, Continue into Start, Start, Start.

Here’s a process to help you stop starting and start finishing.

Open a spreadsheet and list all your projects for the year. At the top of the column, list the projects you’ve completed. Below the completed projects, list your active projects, and below them, list your future (not yet started) projects. Highlight the completed projects and the active projects, and set the print area. Then, select “print on both sides of the page.” When you print the file, the future projects will be printed on the back of the page. This will help you focus on the completed and active projects and block you from trying to start a project before finishing one.

Now, go back to the top of the spreadsheet and select the completed projects and change the font to “strike through.” This will allow you to read the project names and remind yourself of the projects you completed. You can use this list to justify a strong performance rating at your upcoming performance review.

Skip down to the active projects and categorize them as fully staffed or partially staffed. Change the font color to red for the partially staffed projects and move them to the second page with the future projects. Print out the spreadsheet.

The completed projects will be at the top of the page in strike-through font, and the short list of fully staffed projects is listed below them in normal font. On the back of the page, the partially staffed projects are listed in red, and the future projects are listed below them. And now you’re ready to realize the power of the two-sided printout.

Step 1. Ignore the projects on the back of the page (under-staffed and yet to be started projects). They’re still on the do-do list, but they’ll wait patiently on the back of the page until resources are freed up and allocated.

Step 2. Finish the fully staffed projects on the front page.

Step 3. When you finish a project, change the font to “strike-through” and create a list of the freed-up resources.

Step 4. Flip to the back of the page, allocate the freed-up resources to one of the projects, and move the fully staffed project to the front of the page.

Step 5. Proceed to Step 2.

This is a straightforward process, but it requires great discipline.

Here’s a mantra to repeat daily – I will finish a project before I start the next one.

Image credit — iggyshoot

How I Develop Engineering Leaders

For the past two decades, I’ve actively developed engineering leaders. A good friend asked me how I do it, so I took some time to write it down. Here is the curriculum in the form of How Tos:

For the past two decades, I’ve actively developed engineering leaders. A good friend asked me how I do it, so I took some time to write it down. Here is the curriculum in the form of How Tos:

How to build trust. This is the first thing. Always. Done right, the trust-based informal networks are stronger than the formal organization chart. Done right, the informal networks can protect the company from bad decisions. Done right, the right information flows among the right engineers at the right time so the right work happens in the right way.

How to decide what to do next. This is a broad one. We start with a series of questions: What are we doing now? What’s the problem? How do you know? What should we do more of? What should we do less of? What resources are available? When must we be done?

How to map the current state. We don’t define the idealized future state or the North Star, we start with what’s happening now. We make one-page maps of the territory. We use drawings, flow charts, boxes/arrows, and the fewest words. And we take no action before there’s agreement on how things are. The value of GPS isn’t to define your destination, it’s to establish your location. That’s why we map the current state.

How to build momentum. It’s easy to jump onto a moving steam train, but a stationary one is difficult to get moving. We define the active projects and ask – How might we hitch our wagon to a fast-moving train?

How to start something new. We start small and make a thought-provoking demo. The prototype forces us to think through all the elements, makes things real, and helps others understand the concept. If that doesn’t work, we start smaller.

How to define problems so we can solve them easily. We define problems with blocks and arrows, and limit ourselves to one page. The problem is defined as a region of contact between two things, and we identify it with the color red. That helps us know where the problem is and when it occurs. If there are two problems on a page, we break it up into two pages with one problem. Then we decide to solve the problem before, during, or after it occurs.

How to design products that work better and cost less. We create Pareto charts of the cost of the existing product (cost by subassembly and cost by part) and set a cost reduction goal. We create Pareto charts of the part count of the existing product (part count by subassembly and part count by individual part number) and define a goal for part count reduction. We define test protocols that capture the functionality customers care about. We test the existing product and set performance improvement goals for the new one. We test the new product using the same protocols and show the data in a simple A-B format. We present all this data at formal design reviews.

How to define technology projects. We define how the customer does their work. We then define the evolutionary history of our products and services, and project that history forward. For lines of goodness with trajectories that predict improvement, we run projects to improve them. For lines of goodness with stalled trajectories, we run projects to establish new technologies and jump to the next S-curve. We assess our offerings for completeness and create technologies to fill the gap.

How to file the right patents. We ask these questions: How quickly will the customer notice the new functionality or benefit? Once recognized, will they care? Will the patent protect high-volume / high-margin consumables? There are more questions, but these are the ones we start with. And the patent team is an integral part of the technology reviews and product development process.

How to do the learning. We start with the leader’s existing goals and deliverables and identify the necessary How Tos to get their work done. There are no special projects or extra work.

If you’re interested in learning more about the curriculum or how to enroll, send me an email mike@shipulski.com.

Image credit — Paul VanDerWerf

Improve Focus To Improve Effectiveness

Business is about the effective allocation of resources. Companies win when they do that better than their competitors. Full stop. If you believe that, the question is how to allocate resources effectively. To me, everything starts with a map of the territory – a single-page map of today’s projects, the people you have, and the tools/infrastructure you have. In short, before you can reallocate resources, map how you allocate them now.

Business is about the effective allocation of resources. Companies win when they do that better than their competitors. Full stop. If you believe that, the question is how to allocate resources effectively. To me, everything starts with a map of the territory – a single-page map of today’s projects, the people you have, and the tools/infrastructure you have. In short, before you can reallocate resources, map how you allocate them now.

Let the mapping begin.

The first step is to create a one-page summary (a map) of the resources on hand and the projects they work on (how they are allocated). A simple spreadsheet is the way to go. At the top, running left to right, list the names of all the people. Give each person their column. On the left, running top to bottom, list the active projects, one project per row. For each project, move left to right and ask if the person works on the project. Put an X in their column if they contribute to the project in any way. If they work on the project 2% of their time or more, X marks the spot. You will be reluctant to do this, but the process is more meaningful if you do.

No fancy formats, no extra text, no headings, no footers, just columns of people against rows of projects. And it MUST fit one page. MUST. Reduce the font size and the margins to fit it on one page. And if that doesn’t work, set the print area and choose the setting that scales the print area to fit on one page. Put it on 11 by 17 paper if you must, but you must put it on one page. You’ll have to squint to read the font when you do it right.

When you look at the one-page printout, the first thing you will notice is that you have too many rows because you have too many projects. (And, yes, you should list the quiet projects no one knows about.) The second thing you will notice is that everyone has too many Xs because they work on too many projects. The third thing is some people have far more Xs than everyone else’s too many Xs. All the project managers want them on the projects because they are good at getting projects done.

Let the culling begin.

It’s time to stop. The best way to stop is to set a maximum time threshold to deliver the first dollar of revenue. Any project that cannot deliver revenue sooner than the threshold should stop. The threshold method is crude, fast, and effective. It’s a great way to do the first pass culling. For those projects that are difficult to stop due to political factors, don’t stop them but, rather, strongly pause them. Then, use the reallocation process (described later) to move resources to better projects and let the politically charged projects die a slow death. Good process beats bad projects.

Strike the cancelled projects from the record, eliminate their rows, and reprint the one-page map. If you have the right number of projects and they’re fully staffed (this is unlikely), execute the projects that made the cut. If you have too few projects, the next step is to come up with a set of new projects that deliver revenue sooner than the culled projects. If you still have too many projects (too many people with too many Xs), it’s time to thin the herd again. Sort the projects by the revenue they will generate over the threshold period plus three years. The best projects will bubble to the top, and the bad ones will sink to the bottom.

Let the reallocating begin.

Now, delete all the Xs from the spreadsheet so none of the projects are staffed and no one has a project. Start with the top row (your best project), move left to right, and place an X in the columns until the project is fully staffed. Allocate the resources to your best project and get after it right now. Because your best project was understaffed, incremental will flow to the project. This will increase the probability you will hit the launch date or even pull it in.

Next, move down one row to your second-best project and repeat the process. Add Xs left to right until the project is fully staffed. But this time there’s a constraint – each column can contain only one X. Because the people are now fully allocated to and actively working on your best project, they cannot work on the second-best project. With all the Xs in place and your second-best project fully staffed, work the project hard with the reallocated resources. Pull in the timeline if you can.

Repeat the process project by project until you can no longer fully staff a project. And here’s where the game gets interesting. Don’t work a project you cannot staff fully. There. I said it. With new product development projects, there is no partial credit. They’re either 100% done or 0% done. A project that’s 80% done delivers 0% of the revenue. But it’s worse than that. Making “progress” on a project that won’t launch because it’s understaffed consumes functional support resources and will slow down your most important projects. Don’t do that. Don’t run the project. Just don’t. You’re better off paying the people to stay home so they don’t consume functional resources needed by the more important projects.

Instead of paying the people to stay home, try to add them to the active projects so you can launch those sooner. In theory, those projects are fully staffed, but old behaviors die hard, and you probably didn’t fully staff the most important projects. For the people who still don’t have a project (they cannot speed up the projects), train them on the skills/tools they’ll need for the next round of projects. This will help you do the next projects better and faster. Or, they could start on more forward-looking projects that don’t consume resources needed by the more urgent projects.

The process to allocate people to the most important projects is the same for resources like infrastructure for reliability testing or product validation. With the same fully-staff-the-project approach, allocate the infrastructure resources to the most important projects. Once there is no more infrastructure capacity, don’t run an under-resourced project. If you run the lesser project, it will consume those precious infrastructure resources and slow down your most important projects.

You likely won’t be able to staff projects such that each person works on a single project. The concept is more directional than literal. Working on three projects is better than working on four, and two is better than three.

I did not describe how to estimate the project revenues, how to create new projects that deliver more revenue sooner, or how to create the right mix of projects – short, medium, and long. But in a first-things-first way, I suggest you start with a singular focus – reallocate resources to your best projects (and, likely, fewer of them), so those projects effectively deliver revenue your company needs.

I think more focus will bring you more effectiveness.

Image credit — Charlie Wales

How To Reduce the Tariff Signature of Your Supply Chain

Supply chains have taken it on the chin, first from COVID-19 and now from tariffs (or the threat of them). For the second time in several years, we have objective evidence there is more to a supply chain than implementing the lowest-cost way to meet predictable demand. Tariffs have highlighted the cost of an inflexible supply chain because we can quantify the savings from moving parts to countries with lower tariffs.

Supply chains have taken it on the chin, first from COVID-19 and now from tariffs (or the threat of them). For the second time in several years, we have objective evidence there is more to a supply chain than implementing the lowest-cost way to meet predictable demand. Tariffs have highlighted the cost of an inflexible supply chain because we can quantify the savings from moving parts to countries with lower tariffs.

With tariffs, Lean’s mantra of “make it where you sell it” has sharper teeth.

At the most fundamental level, supply chains are governed by the parts. Big parts, big factories; small parts, small machines; high part volume, high volume processes; low part volume, low volume processes; specialized coatings on the parts, specialized suppliers; parts with proprietary materials, sole source supplier. The supply chain is defined by its parts. And when you try to move the manufacture of parts from one country to another, these part-based constraints are the very thing that creates supply chain inflexibility. Said another way, if you want to improve a supply chain’s flexibility, you’ve got to start with the parts. If you want to reduce the tariffs of your supply chain, start with the parts.

All the parts in the supply chain are important but with tariffs, some parts are more important than others. You can make significant improvements in your supply chain’s tariff signature if you know the handful of parts that will deliver the largest tariff reduction. For each part within your supply chain calculate

(material cost x volume x tariff percentage)

and sort the product from largest to smallest. For the top ten parts assess the part-specific constraints that governed the original decision of the supplier and country. For each part identify a country with lower tariffs and pair it with the part-specific constraints. You now have a list of the top ten opportunities to reduce the tariff signature, what must change in the design to move to a lower tariff location, and the entitlement savings. The DFM-based tariff savings for each part is

(part cost x volume x difference in tariff percentage).

Take your top ten list to the product owner and show them the potential savings and ask to meet with the design community so you can explain how each part must change so it can move to a lower tariff country. And tell them how much the company will save if those constraints are overcome. This is like classic Design for Manufacturing (DFM) where the part is changed to reduce the cost to make the part, but, instead, the part is changed to reduce the cost of tariffs.

You now have a playbook for the top ten parts, the estimated tariff savings, and the work required to realize those savings. You don’t have to implement the playbook, but you can. And you can repeat the process for the next ten most important parts (11-20). Now you have a playbook for twenty parts and the estimated savings. You can continue the process as needed and step through the list ten parts at a time.

The process I describe is a good way to reduce the cost of tariffs. But to make a dent in the universe, there’s a much better way. It’s called Design For Assembly, or DFA, which is all about product simplification through part elimination. 35% reductions in the number of parts are typical. With DFA, high-tariff parts aren’t changed, they’re eliminated. But where classic DFA prioritizes eliminating the highest-cost parts, tariff-based DFA prioritizes eliminating parts with the highest tariff costs. The calculations to prioritize DFA-based tariff reduction are similar to those for DFM, but the savings are far more severe – the entire tariff and the part cost are saved. The DFA savings are

(part cost x volume x tariff percentage) + (part cost x volume)

Run the calculation for the parts in your supply chain and sort the results from largest to smallest. Take the list of the top ten to the design community and show them how much they can save if they eliminate the parts. Tell them they’ll be the Heros of the Company if they pull it off. Tell them you help them get the tools and training they’ll need. Repeat for the second group of the ten most important parts (11-20).

DFM and DFA are wildly profitable and with the added savings of tariffs, the savings are beyond wild. If there was ever a time to do DFM and DFA, it’s is now.

Image credit — Derell Licht

Ways To Improve Communication

Clarity. People will know why they dislike (or like) your position, have good ideas on improving it, and appreciate your clarity. Well, at least they’ll recognize you’re communicating differently.

Clarity. People will know why they dislike (or like) your position, have good ideas on improving it, and appreciate your clarity. Well, at least they’ll recognize you’re communicating differently.

Brevity. Make it short.

Visual. When you draw a picture of the situation, people will understand the main system elements and how they interact. Use arrows to describe how the system changes over time. Even better, create a series of snapshots in a time series so you can decide to solve the problem before, during, or after. Words constrict. Use images to create space for divergent perspectives.

Distilled. When you converge on the most important theme, the discussion is focused on the most important thing. And when it strays it’s easy to recognize and put it back to importance. To distill, limit yourself to one page and limit the number of words to twelve. This is unnatural and requires confidence through practice.

Know what you want to communicate. Use fewer and simpler words. Decide what to leave out. Use images and cartoons. Make it clean.

Less is more.

Image credit — Charlie Wales

Mike Shipulski

Mike Shipulski