Posts Tagged ‘no-to-yes’

Purposeful Procrastination

There’s a useful trick when you want to do new work. It has some of the characteristics of procrastination, but it’s different. With procrastination, the problem solver waits to start the solving until it’s almost impossible to meet the deadline. The the solver uses the unreasonable deadline to create internal pressure so they can let go of all the traditional solving approaches. With no time for traditional approaches, the solver must let go of what worked and try a new approach.

There’s a useful trick when you want to do new work. It has some of the characteristics of procrastination, but it’s different. With procrastination, the problem solver waits to start the solving until it’s almost impossible to meet the deadline. The the solver uses the unreasonable deadline to create internal pressure so they can let go of all the traditional solving approaches. With no time for traditional approaches, the solver must let go of what worked and try a new approach.

The heart of the IBE is the Design Challenge, where a team with diverse perspective is brought together by a facilitator to solve a problem in five minutes. The unreasonable time constraint generates all the goodness that comes with procrastination, but, because it’s a problem solving exercise, there’s no drama. And like with procrastination, the teams deliver unimaginable results within an unrealistic time constraint.

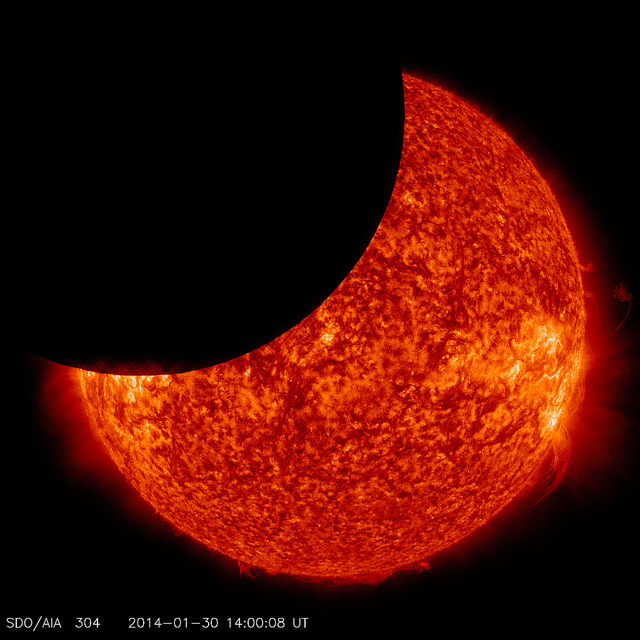

The right time horizon for technology development

Patents are the currency of technology and profits are the currency of business. And as it turns out, if you focus on creating technology you’ll get technology (and patents) and if you focus on profits you’ll get profits. But if no one buys your technology (in the form of the products or services that use it), you’ll go out of business. And if you focus exclusively on profits you won’t create technology and you’ll go out of business. I’m not sure which path is faster or more dangerous, but I don’t think it matters because either way you’re out of business.

Patents are the currency of technology and profits are the currency of business. And as it turns out, if you focus on creating technology you’ll get technology (and patents) and if you focus on profits you’ll get profits. But if no one buys your technology (in the form of the products or services that use it), you’ll go out of business. And if you focus exclusively on profits you won’t create technology and you’ll go out of business. I’m not sure which path is faster or more dangerous, but I don’t think it matters because either way you’re out of business.

It’s easy to measure the number of patents and easier to measure profits. But there’s a problem. Not all patents (technologies) are equal and not all profits are equal. You can have a stockpile of low-level patents that make small improvements to existing products/services and you can have a stockpile of profits generated by short-term business practices, both of which are far less valuable than they appear. If you measure the number of patents without evaluating the level of inventiveness, you’re running your business without a true understanding of how things really are. And if you’re looking at the pile of profits without evaluating the long-term viability of the engine that created them you’re likely living beyond your means.

In both cases, it’s important to be aware of your time horizon. You can create incremental technologies that create short term wins and consume all your resource so you can’t work on the longer-term technologies that reinvent your industry. And you can implement business practices that eliminate costs and squeeze customers for next-quarter sales at the expense of building trust-based engines of growth. It’s all about opportunity cost.

It’s easy to develop technologies and implement business processes for the short term. And it’s equally easy to invest in the long term at the expense of today’s bottom line and payroll. The trick is to balance short against long.

And for patents, to achieve the right balance rate your patents on the level of inventiveness.

Image credit – NASA’s Solar Dynamics Observatory

Even entrepreneurial work must fit with the brand.

To meet ever-increasing growth objectives, established companies want to be more entrepreneurial. And the thinking goes like this – launch new products and services to create new markets, do it quickly and do it on a shoestring. Do that Lean Startup thing. Build minimum viable prototypes (MVPs), show them to customers, incorporate their feedback, make new MVPs, show them again, and then thoselaunch.

To meet ever-increasing growth objectives, established companies want to be more entrepreneurial. And the thinking goes like this – launch new products and services to create new markets, do it quickly and do it on a shoestring. Do that Lean Startup thing. Build minimum viable prototypes (MVPs), show them to customers, incorporate their feedback, make new MVPs, show them again, and then thoselaunch.

For software products, that may work well, largely because it takes little time to create MVPs, customers can try the products without meeting face-to-face and updating the code doesn’t take all that long. But for products and services that require new hardware, actual hardware, it’s a different story. New hardware takes a long time to invent, a long time to convert into an MVP, a long time to show customers and a long time to incorporate feedback. Creating new hardware and launching quickly in an entrepreneurial way don’t belong in the same sentence, unless there’s no new hardware.

For hardware, don’t think smartphones, think autonomous cars. And how’s that going for Google and the other software companies? As it turns out, it seems that designing hardware and software are different. Yes, there’s a whole lot of software in there, but there’s also a whole lot of new sensor systems (hardware). And, what complicates things further is that it’s all packed into an integrated system of subsystems where the hardware and software must cooperate to make the good things happen. And, when the consequences of a failure are severe, it’s more important to work out the bugs.

And that’s the rub with entrepreneurship and an established brand. For quick adoption, there’s strong desire to leverage the established brand – GM, Ford, BMW – but the output of the entrepreneurial work (new product or service) has to fit with the brand. GM can’t launch something that’s half-baked with the promise to fix it later. Ford can come out with a new app that is clunky and communicates intermittently with their hardware (cars) because it will reflect poorly on all their products. In short, they’ll sell fewer cars. And BMW can’t come out with an entrepreneurial all-electric car that handles poorly and is slow off the start. If they do, they’ll sell fewer cars. If you’re an established company with an established brand, the output of your entrepreneurial work must fit with the established brand.

If you’re a software startup, launch it when it’s half-baked and fix it later, as long as no one will die when it flakes out. And because it’s software, iterate early and often. And, there’s no need to worry about what it will do to the brand, because you haven’t created it yet. But if you’re a hardware startup, be careful not to launch before it’s ready because you won’t be able to move quickly and you’ll be stuck with your entrepreneurial work for longer than you want. Maybe, even long enough to sink the brand before it ever learned to swim. Developing hardware is slow. And developing robust hardware-software systems is far slower.

If you’re an established company with an established brand, tread lightly with that Lean Startup thing, even when it’s just software. An entrepreneurial software product that works poorly can take down the brand, if, of course, your brand stands for robust, predictable, value and safety. And if the entrepreneurial product relies on new hardware, be doubly careful. If it goes belly-up, it will be slow to go away and will put a lot of pressure on that wonderful brand you took so long to build.

If you’re an established brand, it may be best to buy your entrepreneurial products and services from the startups that took the risk and made it happen. That way you can buy their successful track record and stand it on the shoulders of your hard-won brand.

Image credit – simpleinsomnia

How to Choose the Best Idea

We have too many ideas, but too few great ones. We don’t need more ideas, we need a way to choose the best one or two ideas and run them to ground.

We have too many ideas, but too few great ones. We don’t need more ideas, we need a way to choose the best one or two ideas and run them to ground.

Before creating more ideas, make a list of the ones you already have. Put them in two boxes. In Box 1, list the ideas without a video of a functional prototype in action. In Box 2, list the ideas that have a video showing a functional prototype demonstrating the idea in action. For those ideas with a functional prototype and no video, put them in Box 1.

Next, throw away Box 1. If it’s not important enough to make a crude physical prototype and create a simple video, the idea isn’t worth a damn. If someone isn’t willing to carve out the time to make a physical prototype, there’s no emotional energy behind the idea and it should be left to die. And when people complain that it’s unfair to throw away all those good ideas in Box 1, tell them it’s unfair to spend valuable resources talking about ideas that aren’t worthy. And suggest, if they want to have a discussion about an idea, they should build a physical prototype and send you the video. Box 2, or bust.

Next, get the band together and watch the short videos in Box 2, and, as a group, put them in two boxes. In Box 3, put the videos without customers actively using the functional prototype. In Box 4, put the videos with customers actively using the functional prototype.

Next, throw way Box 3. If it’s not important enough to make a trip to an important customer and create a short video, the idea isn’t worth a damn. If you’re not willing to put yourself out there and take the idea to an important customer, the idea is all fizzle and no sizzle. Meaningful ideas take immense personal energy to run through the gauntlet, and without a video of a customer using the functional prototype, there’s not enough energy behind it. And when everyone argues that Box 3 ideas are worth pursuing, tell them to pursue a video showing a most important customer demonstrating the functional prototype.

Next, get the band back together to watch the Box 4 videos. Again, put the videos in two boxes. In Box 5 put the videos where the customer didn’t say what they liked and how they’d use it. In Box 6, put the videos where the customer enthusiastically said what they liked and how they’ll use it.

Next, throw away Box 5. If the customer doesn’t think enough about the prototype to tell you how they’ll use it, it’s because they don’t think much of the idea. And when the group says the customer is wrong or the customer doesn’t understand what the prototype is all about, suggest they create a video where a customer enthusiastically explains how they’d use it.

Next, get the band back in the room and watch the Box 6 videos. Put them in two boxes. In Box 7, put the videos that won’t radically grow the top line. In Box 8, put the videos that will radically grow the top line. Throw away Box 7.

For the videos in Box 8, rank them by the amount of top line growth they will create. Put all the videos back into Box 8, except the video that will create the most top line growth. Do NOT throw away Box 8.

The video in your hand IS your company’s best idea. Immediately charter a project to commercialize the idea. Staff it fully. Add resources until adding resources doesn’t no longer pulls in the launch. Only after the project is fully staffed do you put your hand back into Box 8 to select the next best idea.

Continually evaluate Boxes 1 through 8. Continually throw out the boxes without the right videos. Continually choose the best idea from Box 8. And continually staff the projects fully, or don’t start them.

Image credit – joiseyshowaa

For top line growth, think no-to-yes.

Bottom line growth is good, but top line growth is better. But if you want to grow the bottom line, ignore labor costs and reduce material costs. Labor cost is only 5-10% of product cost. Stop chasing it, and, instead, teach your design community to simplify the product so it uses fewer parts and design out the highest cost elements.

Bottom line growth is good, but top line growth is better. But if you want to grow the bottom line, ignore labor costs and reduce material costs. Labor cost is only 5-10% of product cost. Stop chasing it, and, instead, teach your design community to simplify the product so it uses fewer parts and design out the highest cost elements.

Where the factory creates bottom line growth, top line growth is generated in the market/customer domain. The best way I know to grow the top line is to broaden the applicability of your products and services. But, before you can broaden applicability, you’ve got to define applicability as it is. Define the limits of what your product can do – how much it can lift, how fast it can run a calculation and where it can be used. And for your service, define who can use it, where it can be used and what elements without customer involvement. And with the limits defined, you know where top line growth won’t come from.

Radical top line growth comes only when your products and services can be used in new applications. Sure, you can train your sales force to sell more of what you already have, but that runs out of gas soon enough. But, real top line growth comes when your services serve new customers in new ways. By definition, if you’re not trying to make your product work in new ways, you’re not going to achieve meaningful top line growth. And by definition, if you’re not creating new functionality for your services, you might as well be focusing on bottom line growth.

If your product couldn’t do it and now it can, you’re doing it right. If your service couldn’t be used by people that speak Chinese and now it can, you’re on your way. If your product couldn’t be used in applications without electricity and now it can, you’re on to something. If your service couldn’t run on a smartphone and now it can, well, you get the idea.

For the acid test, think no-to-yes.

If your product can’t work in application A, you can’t sell it to people who do that work. If your service can’t be used by visually impaired people, you’re not delivering value to them and they won’t buy it. Turning can’t into can is a big deal. But you’ve got to define can’t before you can turn it into can. If you want top line growth, take the time to define the limits of applicability.

No-to-yes is powerful because it creates clarity. It’s easy to know when a project will create no-to-yes functionality and when it won’t. And that makes it easy to stop projects that don’t deliver no-to-yes value and start projects that do.

No-to-yes is the key element of a compete-with-no-one approach to business.

image credit – liebeslakritze

With novelty, less can be more.

When it’s time to create something new, most people try to imagine the future and then put a plan together to make it happen. There’s lots of talk about the idealize future state, cries for a clean slate design or an edict for a greenfield solution. Truth is, that’s a recipe for disaster. Truth is, there is no such thing as a clean slate or green field. And because there are an infinite number of future states, it’s highly improbable your idealized future state is the one the universe will choose to make real.

When it’s time to create something new, most people try to imagine the future and then put a plan together to make it happen. There’s lots of talk about the idealize future state, cries for a clean slate design or an edict for a greenfield solution. Truth is, that’s a recipe for disaster. Truth is, there is no such thing as a clean slate or green field. And because there are an infinite number of future states, it’s highly improbable your idealized future state is the one the universe will choose to make real.

To create something new, don’t look to the future. Instead, sit in the present and understand the system as it is. Define the major elements and what they do. Define connections among the elements. Create a functional diagram using blocks for the major elements, using a noun to name each block, and use arrows to define the interactions between the elements, using a verb to label each arrow. This sounds like a complete waste of time because it’s assumed that everyone knows how the current state system behaves. The system has been the backbone of our success, of course everyone knows the inputs, the outputs, who does what and why they do it.

I have created countless functional models of as-is systems and never has everyone agreed on how it works. More strongly, most of the time the group of experts can’t even create a complete model of the as-is system without doing some digging. And even after three iterations of the model, some think it’s complete, some think it’s incomplete and others think it’s wrong. And, sometimes, the team must run experiments to determine how things work. How can you imagine an idealized future state when you don’t understand the system as it is? The short answer – you can’t.

And once there’s a common understanding of the system as it is, if there’s a call for a clean sheet design, run away. A call for a clean sheet design is sure fire sign that company leadership doesn’t know what they’re doing. When creating something new it’s best to inject the minimum level of novelty and reuse the rest (of the system as it is). If you can get away with 1% novelty and 99% reuse, do it. Novelty, by definition, hasn’t been done before. And things that have never been done before don’t happen quickly, if they happen at all. There’s no extra credit for maximizing novelty. Think of novelty like ghost pepper sauce – a little goes a long way. If you want to know how to handle novelty, imagine a clean sheet design and do the opposite.

Greenfield designs should be avoided like the plague. The existing system has coevolved with its end users so that the system satisfies the right needs, the users know how to use the system and they know what to expect from it. In a hand-in-glove way, the as-is system is comfortable for end users because it fits them. And that’s a big deal. Any deviation from baseline design (novelty) will create discomfort and stress for end users, even if that novelty is responsible for the enhancement you’re trying to deliver. Novelty violates customer expectations and violating customer expectations is a dangerous game. Again, when you think novelty, think ghost peppers. If you want to know how to handle novelty, imagine a green field and do the opposite.

This approach is not incrementalism. Where you need novelty, inject it. And where you don’t need it, reuse. Design the system to maximize new value but do it with minimum novelty. Or, better still, offer less with far less. Think 90% of the value with 10% of the cost.

Image credit – Laurie Rantala

A Barometer for Uncertainty

Novelty, or newness, can be a great way to assess the status of things. The level of novelty is a barometer for the level of uncertainty and unpredictability. If you haven’t done it before, it’s novel and you should expect the work to be uncertain and unpredictable. If you’ve done it before, it’s not novel and you should expect the work to go as it did last time. But like the barometer that measures a range of atmospheric pressures and gives an indication of the weather over the next hours, novelty ranges from high to low in small increments and so does the associated weather conditions.

Novelty, or newness, can be a great way to assess the status of things. The level of novelty is a barometer for the level of uncertainty and unpredictability. If you haven’t done it before, it’s novel and you should expect the work to be uncertain and unpredictable. If you’ve done it before, it’s not novel and you should expect the work to go as it did last time. But like the barometer that measures a range of atmospheric pressures and gives an indication of the weather over the next hours, novelty ranges from high to low in small increments and so does the associated weather conditions.

Barometers have a standard scale that measures pressure. When the summer air is clear and there are no clouds, the atmospheric pressure is high and on the rise and you should put on sun screen. When it’s hurricane season and super-low system approaches, the drops to the floor and you should evacuate. The nice thing about barometers is they are objective. On all continents, they can objectively measure the pressure and display it. No judgement, just read the scale. And regardless of the level of pressure and the number of times they measure it, the needle matches the pressure. No Kentucky windage. But novelty isn’t like that.

The only way to predict how things will go based on the level of novelty is to use judgement. There is no universal scale for novelty that works on all projects and all continents. Evaluating the level of novelty and predicting how the projects will go requires good judgement. And the only way to develop good judgment is to use bad judgment until it gets better.

All novelty isn’t created equal. And that’s the trouble. Some novelty has a big impact on the weather and some doesn’t. The trick is to know the difference. And how to tell the difference? If when you make a change in one part of the system (add novelty) and the novelty causes a big change in the function or operation of the system, that novelty is important. The system is telling you to use a light hand on the tiller. If the novelty doesn’t make much difference in system performance, drive on. The trick is to test early and often – simple tests that give thumbs-up or thumbs-down results. And if you try to run a test and you can’t get the test to run at all, there’s a hurricane is on the horizon.

When the work is new, you don’t really know which novelty will bite you. But there’s one rule: all novelty will bite you until proven otherwise. Make a list of the novel elements of the and test them crudely and quickly.

Additive Manufacturing’s Holy Grail

The holy grail of Additive Manufacturing (AM) is high volume manufacturing. And the reason is profit. Here’s the governing equation:

The holy grail of Additive Manufacturing (AM) is high volume manufacturing. And the reason is profit. Here’s the governing equation:

(Price – Cost) x Volume = Profit

The idea is to sell products for more than the cost to make them and sell a lot of them. It’s an intoxicatingly simple proposition. And as long as you look only at the volume – the number of products sold per year – life is good. Just sell more and profits increase. But for a couple reasons, it’s not that simple. First, volume is a result. Customers buy products only when those products deliver goodness at a reasonable price. And second, volume delivers profit only when the cost is less than the price. And there’s the rub with AM.

Here’s a rule – as volume increases, the cost of AM is increasingly higher than traditional manufacturing. This is doubly bad news for AM. Not only is AM more expensive, its profit disadvantage is particularly troubling at high volumes. Here’s another rule – if you’re looking to AM to reduce the cost of a part, look elsewhere. AM is not a bottom-feeder technology.

If you want to create profits with AM, use it to increase price. Use it to develop products that do more and sell for more. The magic of AM is that it can create novel shapes that cannot be made with traditional technologies. And these novel shapes can create products with increased function that demand a higher price. For example, AM can create parts with internal features like serpentine cooling channels with fine-scale turbulators to remove more heat and enable smaller products or products that weigh less. Lighter automobiles get better fuel mileage and customers will pay more. And parts that reduce automobile weight are more valuable. And real estate under the hood is at a premium, and a smaller part creates room for other parts (more function) or frees up design space for new styling, both of which demand a higher price.

Now, back to cost. There’s one exception to cost rule. AM can reduce total product cost if it is used to eliminate high cost parts or consolidate multiple parts into a single AM part. This is difficult to do, but it can be done. But it takes some non-trivial cost analysis to make the case. And, because the technology is relatively new, there’s some aversion to adopting AM. An AM conversion can require a lot of testing and a significant cost reduction to take the risk and make the change.

To win with AM, think more function AND consolidation. More (or new) function to support a higher price (and increase volume) and reduced cost to increase profit per part. Don’t do one or the other. Do both. That’s what GE did with its AM fuel nozzle in their new aircraft engines. They combined 20 parts into a single unit which weighed 25 percent less than a traditional nozzle and was more than five times as durable. And it reduced fuel consumption (more function, higher price).

AM is well-established in prototyping and becoming more established in low-volume manufacturing. The holy grail for AM – high volume manufacturing – will become a broad reality as engineers learn how to design products to take advantage of AM’s unique ability to make previously un-makeable shapes and learn to design for radical part consolidation.

More function AND radical part consolidation. Do both.

Image credit – Les Haines

The Three Rs of Innovation – Risk, Reward, and Resources

Is it innovation or continuous improvement or is it innovation? Is it regular innovation or disruptive innovation? Is it new enough or too new? These questions are worse than meaningless as they suck emotional energy from the organization and divert emotional energy from the business objective.

Is it innovation or continuous improvement or is it innovation? Is it regular innovation or disruptive innovation? Is it new enough or too new? These questions are worse than meaningless as they suck emotional energy from the organization and divert emotional energy from the business objective.

With every initiative, there are risks, rewards, and resources. Risk generally tracks with newness, reward usually tracks with incremental customer goodness and resources are governed by the work. Risk is about the probability of tackling the newness, reward is about the size of the prize and resources are about how the work is done. There is no best amount of risk as sometimes the right amount is none and other times it’s more than everyone prefers. And there’s no best amount of reward as it depends on the company’s goals. And there’s no right amount of resources because there’s no right scope. For all three – risk, reward and resources – the right amount depends on the context.

For bottom line projects, it’s about maintaining product functionality while eliminating waste. And while there’s no right amount of risk, reward and resources, three filters (people, process, tools) can help get everyone on the same page.

Here are the escalating categories for people – no new people, move people from group A to group B, hire more people like the ones we have, hire new people with skills we don’t have. And for categories for process – no new processes, eliminate steps of existing processes, add steps to existing processes, create a process that’s new to the facility, create a process that’s new to the company, create process that’s new to the industry, create a process that’s new to the world. And for tools – no new tools, modify existing tools, buy new tools, create new tools from scratch.

There are no right answers, but if you’ve got to hire people you’ve never hired, create processes that are new-to-world, and invent new tools, it’s clear to everyone the project is pushing the envelope. And if the reward is significant and resources are plentiful, it could be a good way to go. And if there are no new hires, no new processes, and no new tools, don’t expect extravagant rewards. It’s not an exact science, but categorizing the newness in people, process, and tools and then comparing with the reward (payoff) makes clear any mismatches. And when mismatches are clear they can be managed. Resources can be added, the scope can be reduced and reward can be revisited.

For top line projects, it’s about providing novel usefulness to customers at a reasonable cost. And while risk, reward, and resources must be balanced, the filters are different. For top line, the filters are breadth of applicability, competition, is/isn’t.

Here are the escalating categories for breadth of applicability – same customer in the same application, same customers in a new application, new customers in a new market, new customers in different industry, new customers in an industry created by the project. For competition – many competitors in the same industry, fewer competitors in the same industry, fewer competitors in a different industry, no competitors (compete with no one.) And for is/isn’t – improve what is, radically improve what is, create what isn’t.

Again, no right answers. But the plan is to sell to the same customers into markets with the same powerful competitors with only a slight improvement to the existing product, don’t expect radical rewards and don’t run a project that consumes significant resources. And, if the plan is to create a whole new industry where there are no competitors and it requires an entirely new service that doesn’t yet exist, the potential reward should be spectacular, expect to allocate a boatload of resources and prepare for the project to take longer than expected or to be cancelled before completion.

Balancing risk, reward and resources is not an exact science. And the only way to get good at it is to calibrate new projects based on previous projects. To start the calibration process, try the process on your most recent completed projects. Categorize the projects with the relevant filters and define the resources consumed and the realized rewards. And when planning the next project, categorize with the filters and define the resource plan and planned rewards and see how they compare with the completed projects. And if there are mismatches, reconcile them with the realities of the previous projects.

Image credit – Ian Sane

Learn in small batches, rinse and repeat.

When the work is new, it can’t be defined and managed like work that has been done before.

When the work is new, it can’t be defined and managed like work that has been done before.

Sometimes there’s a tendency to spend months to define the market, the detailed specification and the project timeline and release the package as a tidal wave that floods the organization with new work. Instead, start with a high-level description of the market, a rough specification and the major project milestones, all of which will morph, grow and inform each other as the team learns. Instead of a big batch, think bite-sized installments that build on each other. Think straw-man that gets its flesh as the various organizations define their learning objectives and learn them.

Instead of target customer segments and idealized personas, define how the customers will interact with the new product or service. Use the storyboard format to capture sequence of events (what they do), the questions they ask themselves and how they know they’ve done it right. Make a storyboard for the top three to five most important activities the customers must do. There’s good learning just trying to decide on the top three to five activities, never mind the deep learning that comes when you try to capture real activities of real customers. [Hint – the best people to capture real customer activities are real customers.]

Instead of a detailed list of inputs and outputs, fill in the details of the storyboards. Create close-ups of the user interfaces and label the dials, buttons and screens. When done well, the required inputs and outputs bubble to the surface. And define the customer’s navigation path, as it defines the sequence of things and where the various inputs come to be and the various outputs need to be. What’s nice is learning by iteration can be done quickly since its done in the domain of whiteboards and markers.

Instead of defining everything, just define what’s new and declare everything else is the same as last time.

The specification for the first prototypes is to bring the storyboards to life and to show the prototypes to real customers. Refine and revise based on the learning, and rinse and repeat, as needed.

As the design migrates toward customer value and confidence builds, it’s then time to layer on the details and do a deep dive into the details – specs, test protocols, manufacturing, sales and distribution.

At early stages of innovation work, progress isn’t defined by activity, it’s defined by learning. And it can look like nothing meaningful is happening as there is a lot of thinking and quiet time mixed in with infrequent bursts active activity. But that’s what it takes to answer the big questions of the front end.

When in doubt, answer the big questions at the expense of the details. And to stay on track, revisit and refine the learning objectives. And to improve confidence, show it to real customers.

And rinse and repeat, as needed.

Image credit – Jason Samfield

How To Create Eye-Watering Ideas

With creativity, the leading thinking says the most important thing is to create many of ideas. When asked to generate many of ideas, the thinking goes, the team lets go of their inhibitions and good ideas slip through their mental filters. I’ve found that thinking misleading. I’ve found that creating many ideas results in many ideas, but that’s it. Before the session to create new ideas, you already had a pile of ideas you weren’t working on, and after the session is bigger, but not better.

With creativity, the leading thinking says the most important thing is to create many of ideas. When asked to generate many of ideas, the thinking goes, the team lets go of their inhibitions and good ideas slip through their mental filters. I’ve found that thinking misleading. I’ve found that creating many ideas results in many ideas, but that’s it. Before the session to create new ideas, you already had a pile of ideas you weren’t working on, and after the session is bigger, but not better.

What’s needed is several outlandish ideas that make your hair stand on end. The ideas should be so different that they cause you to chuckle to mask your discomfort. These ideas should be borderline unbelievable and just south of impossible. The ideas should have the possibility to change the game and tip your industry on its head.

The “many ideas” thinking has the right intent – to loosen the team’s thinking so they generate good ideas, but the approach is insufficient. To force the team to generated outlandish ideas they must be turned inside-out and put on the rack. Heretical ideas don’t come easily and drastic measures are needed. The team must be systematically stripped of the emotional constraints of their success using the Innovation Burst Event (IBE) method.

To prepare for the IBE, a reward-looking analysis is done to identify traditional lines of customer goodness (for example, miles per gallon for automobiles) and define how that goodness has changed over time (position it on the S-curve.) If the improvement has been flat, it’s time for a new line of customer goodness, and if the goodness is still steadily increasing, it’s time to create a new technology that will provide the next level of improvement. With this analysis the disposition of the system is defined and potentially fertile design space is identified. And within this design space, design challenges are created that force the team to exercise the highly fertile design space during the IBE.

Everything about the IBE is designed to strip the team of its old thinking. The IBE is held at an offsite location to change the scenery and eliminate reminders of traditional thinking and good food is served to help the team feel the day is special. But the big medicine is the design challenges. They are crafted to outlaw traditional thinking and push the team toward new thinking. The context is personal (not corporate) and the scale of the challenge is purposefully small to help the team let go of adjacent concerns. And, lastly, the team is given an unreasonably short time (five to ten minutes) to solve the problem and build a thinking prototype (a prototype that stands for an idea, not at functional prototype.)

Everything about the IBE helps the team let go of their emotional constraints and emit eye-watering solutions. The design challenges force them to solve problems in a new design space in a way and does not give them a chance to limit their thinking in any way. The unrealistic time limit is all-powerful.

Four design challenges is about all team can handle in the one-day IBE. With the IBE they come up with magical ideas clustered around four new areas, new areas that have the potential to flip your industry on its head. In one day, a team can define market-changing ideas that obsolete your best products and even your business model. Not bad for one day.

It may be popular wisdom that it’s best to create many new ideas, but it’s not the best way. And it contradicts popular belief that a team can create three or four game-changing ideas in a single day. But the IBEs work as advertised.

Don’t waste time creating a pile of ideas. Spend the time to identify fertile design space and hold a one-day IBE to come up with ideas that will create your future.

Image credit – moonjazz

Mike Shipulski

Mike Shipulski