Posts Tagged ‘Design for Assembly’

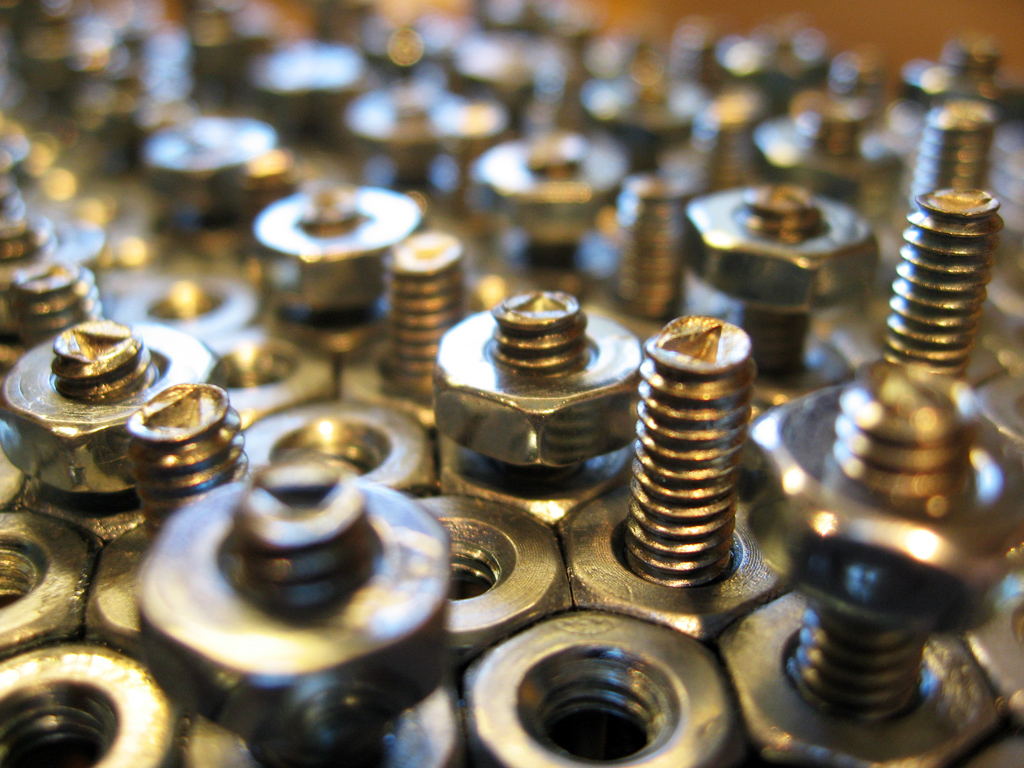

Fasteners Can Consume 20-50% of Assembly Labor

The data-driven people in our lives tell us that you can’t improve what you can’t measure. I believe that. And it’s no different with product cost. Before improving product cost, before designing it out, you have to know where it is. However, it can be difficult to know what really creates cost. Not all parts and features are created equal; some create more cost than others, and it’s often unclear which are the heavy hitters. Sometimes the heavy hitters don’t look heavy, and often are buried deeply within the hidden factory.

The data-driven people in our lives tell us that you can’t improve what you can’t measure. I believe that. And it’s no different with product cost. Before improving product cost, before designing it out, you have to know where it is. However, it can be difficult to know what really creates cost. Not all parts and features are created equal; some create more cost than others, and it’s often unclear which are the heavy hitters. Sometimes the heavy hitters don’t look heavy, and often are buried deeply within the hidden factory.

Measure, measure, measure. That’s what the black belts say. However, it’s difficult to do well with product cost since our costing methods are hosed up and our measurement systems are limited. What do I mean? Consider fasteners (e.g., nuts, bolts, screws, and washers), the product’s most basic life form. Because fasteners are not on the BOM, they’re not part of product cost. Here’s the party line: it’s overhead to be shared evenly across all the products in a socialist way. That’s not a big deal, right? Wrong. Although fasteners don’t cost much in ones and twos, they do add up. 300-500 pieces per unit times the number of units per year makes for a lot of unallocated and untracked cost. However, a more significant issue with those little buggers is they take a lot of time attach to the product. For example, using standard time data from DFMA software, assembly of a 1/4″ nut with a bolt, locktite, a lockwasher, and cleanup takes 50 seconds. That’s a lot of time. You should be asking yourself what that translates to in your product. To figure it out, multiply the number nut/bolt/washer groupings by 50 seconds and multiply the result by the number of units per year. Actually, never mind. You can’t do the calculation because you don’t know the number of nut/bolt/washer combinations that are in your product. You could try to query your BOMs, but the information is likely not there. Remember, fasteners are overhead and not allocated to product. Have you ever tried to do a cost reduction project on overhead? It’s impossible. Because overhead inflicts pain evenly to all, no one is responsible to reduce it.

With fasteners, it’s like death by a thousand cuts.

The time to attach them can be as much as 20-50% of labor. That’s right, up to 50%. That’s like paying 20-50% of your folks to attach fasteners all day. That should make you sick. But it’s actually worse than that. From Line Design 101, the number of assembly stations is proportional to demand times labor time. Since fasteners inflate labor time, they also inflate the number of assembly stations, which, in turn, inflates the factory floor space needed to meet demand. Would you rather design out fasteners or add 15% to your floor space? I know you can get good deals on factory floor space due to the recession, but I’d still rather design out fasteners.

Even with the amount of assembly labor consumed by fasteners, our thinking and computer systems are blind to them and the associated follow-on costs. And because of our vision problems, the design community cannot be held accountable to design out those costs. We’ve given them the opportunity to play dumb and say things like, “Those fastener things are free. I’m not going to spend time worrying about that. It’s not part of the product cost.” Clearly not an enlightened statement, but it’s difficult to overcome without cost allocation data for the fasteners.

The work-around for our ailing thinking and computer-based cost tracking systems is simple: get the design engineers out to the production floor to build the product. Have them experience first hand how much waste is in the product. They’ll come back with a deep-in-the-gut understanding of how things really are. Then, have them use DFMA software to score the existing design, part-by-part, feature-by-feature. I guarantee everyone will know where the cost is after that. And once they know where the cost is, it will be easy for them to design it out.

I have data to support my assertion that fasteners can make up 20-50% of labor time, but don’t take my word for it. Go out to the factory floor, shut your eyes and listen. You’ll likely hear the never ending song of the nut runners. With each chirp, another nut is fastened to its bolt and washer, and another small bit of labor and factory floor space is consumed by the lowly fastener.

DFA and Lean – A Most Powerful One-Two Punch

Lean is all about parts. Don’t think so? What do your manufacturing processes make? Parts. What do your suppliers ship you? Parts. What do you put into inventory? Parts. What do your shelves hold? Parts. What is your supply chain all about? Parts.

Lean is all about parts. Don’t think so? What do your manufacturing processes make? Parts. What do your suppliers ship you? Parts. What do you put into inventory? Parts. What do your shelves hold? Parts. What is your supply chain all about? Parts.

Still not convinced parts are the key? Take a look at the seven wastes and add “of parts” to the end of each one. Here is what it looks like:

- Waste of overproduction (of parts)

- Waste of time on hand – waiting (for parts)

- Waste in transportation (of parts)

- Waste of processing itself (of parts)

- Waste of stock on hand – inventory (of parts)

- Waste of movement (from parts)

- Waste of making defective products (made of parts)

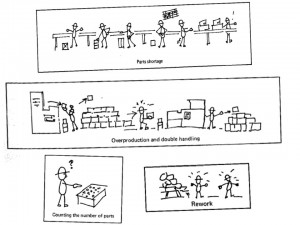

And look at Suzaki’s cartoons. (Click them to enlarge.) What do you see? Parts.

Take out the parts and the waste is not reduced, it’s eliminated. Let’s do a thought experiment, and pretend your product had 50% fewer parts. (I know it’s a stretch.) What would your factory look like? How about your supply chain? There would be: fewer parts to ship, fewer to receive, fewer to move, fewer to store, fewer to handle, fewer opportunities to wait for late parts, and fewer opportunities for incorrect assembly. Loosen your thinking a bit more, and the benefits broaden: fewer suppliers, fewer supplier qualifications, fewer late payments; fewer supplier quality issues, and fewer expensive black belt projects. Most importantly, however, may be the reduction in the transactions, e.g., work in process tracking, labor reporting, material cost tracking, inventory control and valuation, BOMs, routings, backflushing, work orders, and engineering changes.

However, there is a big problem with the thought experiment — there is no one to design out the parts. Since company leadership does not thrust greatness on the design community, design engineers do not have to participate in lean. No one makes them do DFA-driven part count reduction to compliment lean. Don’t think you need the design community? Ask your best manufacturing engineer to write an engineering change to eliminates parts, and see where it goes — nowhere. No design engineer, no design change. No design change, no part elimination.

It’s staggering to think of the savings that would be achieved with the powerful pairing of DFA and lean. It would go like this: The design community would create a low waste design on which the lean community would squeeze out the remaining waste. It’s like the thought experiment; a new product with 50% fewer parts is given to the lean folks, and they lean out the low waste value stream from there. DFA and lean make such a powerful one-two punch because they hit both sides of the waste equation.

DFA eliminates parts, and lean reduces waste from the ones that remain.

There are no technical reasons that prevent DFA and lean from being done together, but there are real failure modes that get in the way. The failure modes are emotional, organizational, and cultural in nature, and are all about people. For example, shared responsibility for design and manufacturing typically resides in the organizational stratosphere – above the VP or Senior VP levels. And because of the failure modes’ nature (organizational, cultural), the countermeasures are largely company-specific.

What’s in the way of your company making the DFA/lean thought experiment a reality?

DFA Saves More than Six Sigma and Lean

I can’t believe everyone isn’t doing Design for Assembly (DFA), especially in these tough economic times. It’s almost like CEOs really don’t want to grow stock price. DFA, where the product design is changed to reduce the cost of putting things together, routinely achieves savings of 20-50% in material cost, and the same for labor cost. And the beauty of the material savings is that it falls right to the bottom line. For a product that costs $1000 with 60% material cost ($600) and 10% profit margin ($100), a 10% reduction in material cost increases bottom line contribution by 60% (from $100 to $160). That sounds pretty good to me. But, remember, DFA can reduce material cost by 50%. Do that math and, when you get up off the floor, read on.

Unfortunately for DFA, the savings are a problem – they’re too big to be believed. That’s right, I said too big. Here’s how it goes. An engineer (usually an older one who doesn’t mind getting fired, or a young one who doesn’t know any better) brings up DFA in a meeting and says something like, “There’s this crazy guy on the web writing about DFA who says we can design out 20-50% of our material cost. That’s just what we need.” A pained silence floods the room. One of the leaders says something like, “Listen, kid, the only part you got right is calling that guy crazy. We’re the world leaders in our field. Don’t you think we would have done that already if it was possible? We struggle to take out 2-3% material cost per year. Don’t talk about 20-50% because is not possible.” DFA is down for the count.

Also unfortunate is the name – DFA. You’ve got to admit DFA doesn’t roll off the tongue like six sigma which also happens to sound like sex sigma, where DFA does not. I think we should follow the lean sigma trend and glom some letters onto DFA so it can ride the coat tails of the better known methodologies. Here are some letters that could help:

Lean DFA; DFA Lean; Six Sigma DFA; Six DFA Sigma (this one doesn’t work for me); Lean DFA Sigma

Its pedigree is also a problem – it’s not from Toyota, so it can’t be worth a damn. Maybe we should make up a story that Deming brought it to Japan because no one in the west would listen to him, and it’s the real secret behind Toyota’s success. Or, we can call it Toyota DFA. That may work.

Though there is some truth to the previous paragraphs, the main reason no one is doing DFA is simple:

No one is asking the design community to do DFA.

Here is the rationalization: The design community is busy and behind schedule (late product launches). If we bother them with DFA, they may rebel and the product will never launch. If we leave them alone and cross our fingers, maybe things will be all right. That is a decision made in fear, which, by definition, is a mistake.

The design community needs greatness thrust upon them. It’s the only way.

Just as the manufacturing community was given no choice about doing six sigma and lean, so should the design community be given no choice about doing DFA.

No way around it, the first DFA effort is a leap of faith. The only way to get it off the ground is for a leader in the organization to stand up and say “I want to do DFA.” and then rally the troops to make it happen.

I urge you to think about DFA in the same light as six sigma or lean: If your company had a lean or six sigma project that would save you 20-50% on your product cost, would you do it? I think so.

Who in your organization is going to stand up and make it happen?

Successful Design For Assembly

Successful Design For Assembly

Each company works with design for assembly (DFA) methods for different reasons. Some companies want to take cost out of their products, some want to make more products in their factories, and some want to simplify the product to increase quality and reliability.

In a growing market, a company wants to reduce labor content to get more products through the factory and to meet demand without adding assembly workers. In a growing market, a company also wants to reduce the floor space required to meet demand without building another factory. Read the rest of this entry »

Six Lessons Learned from a Successful Design For Assembly Program

Six Lessons Learned DFA paper for May 2006 DFMA Forum.pdf (8 pages)

Each company works with Design for Assembly (DFA) methods for different reasons. Some companies want to take cost out of their products, some want to make more products in their factories, and some want to simplify the product to increase quality and reliability. In a growing market a company wants to reduce labor content to get more products through the factory to meet demand without adding assembly workers. And, in a growing market a company wants to reduce the required floor space required to meet demand without building another factory. Remarkably, the goals are similar for Read the rest of this entry »

Mike Shipulski

Mike Shipulski